Innovations in agro processing for poor farmer and

advertisement

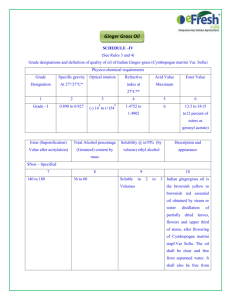

Innovations in agro processing for poor farmer and cultivator communities in hilly regions-project by NIIST, Trivandrum and implemented by the agro processing group with scientists like Dr.C.Arumughan,M.M.Sreekumar and aDr.A.Sundaresan in the lead, and involving scientists and technical staff in the group-details for this entry being prepared by S.Sureshkumar,scientist and Advisor to Director,NIIST ,on behalf of the agency, in consultation The project ,which was initiated as a technology incubation effort with governmental support, based on a novel process for value added products from fresh spices, really received a boost when MATA an NGO under the aegis of Rishang Keishing foundation approached the laboratory,NIIST[formerly RRL],Trivandrum ,under the CSIR ,a public funded research agency, for implementing a pilot project in the hilly regions of Manipur ,in the North –East where ginger was being cultivated, by poor farming communities. Their income was limited due to the difficulties on account of wet weather conditions affecting drying operations coupled with the handicaps in transport and haulage that the difficult mountainous terrain provided. This often lead to the crop being spoiled, since further processing for value additions elsewhere were based on drying as the first step. There was no viable process for oils and oleoresins from fresh ginger, which would ameliorate the difficulties of the farmer community in the region besides ensuring adequate returns and increased income from further processing, for value addition, as above. M.M.Sreekumar, scientist of NIIST with the help of N.Sudhilal technical assistant had developed at the laboratory scale a process for extracting oils and oleoresins as value added products from fresh ginger, which also ensured better yield and quality profiles, in the laboratory trials. This was made part of a project proposal that S.Sureshkumar and M.M.Sreekumar, scientist, NIIST, submitted to DSIR for governmental/departmental special funding support under a technology business incubator facility program, which was mooted, in alliance with Spices Board and the laboratory. Some pilot processing facilities could be built up under the leadership of Dr.C.Arumughan, Head of the group and Dr.A.Sundaresan scientist, in addition to the above team. Dr.A.D.Damodaran, Director of the laboratory at that time gave all the institutional support for the pilot project, with funds from CSIR. Around this time MATA an NGO under the aegis of Rishang Keishing foundation approached the laboratory through DSIR, with funding support under the PATSER Scheme for innovations and their industrial implementation, as risk capital coverage. Scientists M.M.Sreekumar and Dr.A.Sundaresan visited the location to assess the logistics and feasibility for project implementation as a Demonstration and industrial scale operation, for benefiting the poor farmer communities of the region. If found successful this can diffuse in the North-East with special funding support from government and technical support from the laboratory and execution support from project engineering companies, involving interested agencies, in the private, voluntary and governmental, as well as research sectors. The project could be successfully implemented overcoming all the logistical and technical as well as administrative difficulties in time ,and the viability of the project established through product trial marketing, which showed the superior aroma profile of the products from fresh ginger. The team could also use the facility after trials at the laboratory scale and bench scale, to prove the process and its applications for other fresh spices like turmeric and pepper, thus increasing the profitability and viability of the project as well as its attractiveness for the farming communities and the industrial entrepreneurship options. Taking to such economic activities based on post harvest technology increased the farmer community stakes in cultivation attracting more people to turn to such profitable activities, including the youth and adult population, alike. This was a perfect example of national integration through technology, as pointed out by the then DG of CSIR, who used to refer often to the phrase `from guns to gunny bags` to emphasize the scope for solving the problems of unrest and violence in the region through technology, and innovations based on science, involving different sectors effectively, as above. The diffusion of the technology was also facilitated by this success in the pilot stage, so that in the subsequent phases it has spread to Meghalaya and Sikkim, based on a strategy plan for technology diffusion, where the projects are being implemented, involving stakeholders, as above, for the benefit of farmer communities in hilly regions, based on innovations in agro processing. In later stages there are also plans to develop the scope of the project further by down streaming of technology aimed at more value added products like extracts and fractions for food, health and nutraceutical applications, from spices, with possible extension to other natural products of the region, which has a scope for cultivation and processing for value additions, locally,in these and other similar high altitude locations. Some studies on sea buckthorn grown in Tibetan mountains have been carried out earlier as part of an overall strategy in this context. Presently the laboratory is undertaking research studies as part of a suprainstitutional project in the group, with CSIR support, and involving scientists and technical staff from relevant disciplines and divisions, for nutraceutical from natural products. Some of the findings of which will be developed further as bench scale and demonstration scale processes to be engineered at demonstration and industrial scales as above, eventually. As per the strategy, a basket of processes will be aimed at technogical innovations for farmer communities in rural/high altitude regions. An observation from the principal innovator based on a news story about the pilot project-the story tells a tale about the externalities of the technology diffusion process benefiting poor communities Sometime in early 2000, Litan 40 km off Imphal, Manipur, India was just like any other village in NE with ladies sitting on the road side trying to sell small quantities of ginger they harvested the previous day. Most men, faced with starvation and dragged to drugs and liquor, huddle in front of the small shops and work hard to kill time. But setting of the ginger processing facility by end of December 2000 made a drastic change in the small town. For the erection of the plant and machinery, skilled labor from the main land was brought in. They started staying in the processing plant and to cater to the need of these people, small tea shops started functioning which later transformed into lunch homes and later to full time hotels. Soon other shops started coming up in the region, a video shop, a barber shop, several shops selling consumer goods, woolen clothing etc. It became a major bus terminal and people started carrying gunny bags of ginger to the processing facility . The plant started buying from the local farmers 20 tons of ginger per day and soon message spread to other villages and the farmers started feeding their produce to the factory. In a couple of months most of the buses plying in the route were unloading bags of ginger at Litan and the traffic increased. The change was visible in the way people lived and the way the small bus stop was transformed into a major trading centre. M.M.Sree Kumar Scientist "F" National Institute for Interdisciplinary Science & Technology (NIIST) (formerly Regional Research Laboratory ) Trivandrum - 695 019 INDIA Phone ( O): 91- 471 - 2515 273 Fax: 91- 471-2495050 SURESHKUMAR.S SCIENTIST AND ADVISER TO DIRECTOR, NIIST PH-91-471-1515333