Lab 1

advertisement

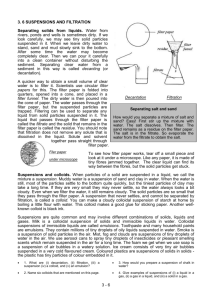

Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I LABORATORY 1: Preparation of suspensions and selection of stabilizers 1. LABORATORY OBJECTIVES a) To learn the preparation methods of suspensions. b) To know the definition of sedimentation volume and familiarize with the measurement method. c) To learn how to select stabilizers based on the properties of the drug substances. 2. INTRODUCTION Suspensions are defined as preparations containing finely divided drug particles (the suspensoid) dispersed uniformly in a liquid medium in which the drug exhibits limited solubility. In most stable pharmaceutical suspensions, the particle diameter is about 1 to 50 µm. There are many factors to be considered when developing and preparing a pharmaceutically elegant suspension. In addition to the therapeutic efficacy, chemical stability of the formulation components, and esthetic appearance of the preparation, a properly prepared pharmaceutical suspension should settle slowly and be readily resuspended upon gentle shaking without the formation of a solid cake on standing. Furthermore, the particle size of the suspensoid should remain unchanged in the vehicle throughout the product shelf-life and an accurate dose should be readily withdrawn from the container either by pouring or by means of a syringe. The various factors governing the rate of settling of a particle in a suspension are described by the Stokes’ equation which is presented as: 2 r 2 ( 1 2 ) g V 9 where V is the rate of settling, r is the particle radius, ρ1 is the density of the particle, ρ2 is the density of the medium, g is the gravitational constant, and η is the viscosity of the medium. A number of factors can be adjusted to enhance the physical stability of a suspension, including the diameter of the particles, the density, and the viscosity of the medium. From the Stokes’ equation, it is apparent that the velocity of sedimentation of a particle is faster for larger particles than smaller particles when all other factors remain constant. Reducing the particle size of the dispersed phase can result in a slower rate of settling of the particles. Also, the greater the density of the particles, the faster is the rate of sedimentation when the density of the vehicle is kept constant. The rate of sedimentation may be significantly 1 Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I reduced by increasing the viscosity of the dispersion medium and this approach has shown some success in formulating suspension products. In commercial suspension formulations, suspending agents such as carboxymethylcellulose, methylcellulose, tragacanth, and xanthan gum are often added to enhance the viscosity of the dispersion medium. The wetting of the suspensoid is a primary concern in the preparation of suspensions. Hydrophilic substances are readily wetted by water or other polar liquids because of low interfacial tension and the resultant small contact angles. A hydrophobic substance is often difficult to disperse and the powder may just float on the surface of the liquid despite its higher density. To improve the wetting characteristics of a hydrophobic drug powder, anionic or nonionic surfactants are often used. Fine particles have a tendency to form a compact cake upon settling to the bottom of the container. The cake is very difficult to breakup upon shaking. To avoid the formation of a cake, it is necessary to prevent aggregation of particles giving rise to non-dispersable large aggregates. One common method of preventing aggregation of particles of a suspension is via the formation of a less rigid or loose agglomerates of particles held together by comparatively weak inter-particle forces. Such an agglomeration process of particles is termed the formation of a floc or a floccule, within which particles are loosely linked through van der Waals forces. Although flocs settle more rapidly than small individual particles, the presence of dispersion medium within the settling flocs makes them less prone to compaction as compared to deflocculated particles. The flocs settle to form a higher sediment volume than the deflocculated particles. The loosely linked structures of the flocculated particles allow the easy break up and redispersion of the particles upon gentle agitation. The zeta potential is a measurable parameter which indicates the electrical charges associated with particles in the dispersion medium. When the zeta potential is relatively high, the repulsive forces between particles usually exceed the inter-particle attractive forces. When the particles are individually dispersed, they are said to be in the deflocculated state. Thus, deflocculated particles settle separately and the rate of sedimentation is governed by the Stokes’ equation. The supernatant remains cloudy during the sedimentation process and the resultant sediment is very difficult to resuspend. There are several methods for the preparation of flocculated suspensions. Electrolytes can act as a flocculating agent which reduces the electrostatic repulsion between the particles and facilitates the linking between particles via attractive forces. The addition of an appropriate concentration of nonionic or ionic surface-active agents can also induce flocculation of particles in a suspension leading to a higher sedimentation volume. Suspensions can be prepared by the dispersing method or the coaggregation method. In the dispersing method, if the drug particles tend to clump together or float on the surface of the vehicle, the powder must first be wetted to facilitate the dispersion of the particles in the liquid medium. Alcohol, glycerin, propylene glycol, and other polar liquids can be employed as the wetting agent when the dispersion medium is an aqueous vehicle. Once 2 Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I the powder is wetted properly, the dispersion medium is added in portions to the powder and the mixture is thoroughly mixed before the additional portions of vehicle are added. The last portion of the vehicle is used to rinse the mixing equipment and to bring the suspension to the final volume. The final product is then passed through a colloid mill or other dispersion or mixing equipment to ensure even dispersion of the finished product. In the coaggregation methods, drug substance existing in the ionic or molecular state are converted into microparticles by using physical or chemical method. The microparticles are subsequently dispersed in the liquid medium to form a uniform suspension. Suspensions are generally evaluated with respect to their particle-size distribution, electrokinetic properties (zeta potential), and rheological characteristics. A number of evaluating methods can be applied to a suspension product such as sedimentation volume, resuspendability, and specific gravity measurements. The sedimentation volume (F) of a suspension can be determined using a graduate cylinder. It is defined as the ratio of the equilibrium volume of the sediment to the total volume of the suspension. The greater the value of F, the more stable is the product. On the label of a suspension product, “Shake Before Use” is stated to ensure uniform dispersion of the solid particles prior to the withdrawal of the desired dose. For the dosing accuracy concerns, the suspension dosage form is not recommended for drugs with a very narrow therapeutic window. 3. METHODS 3.1 Preparation of suspensions of hydrophilic drugs and measurement of sedimentation volume 3.1.1 Formulations Table 1 Formulations of zinc oxide suspensions No. 1 2 3 4 Zinc oxide (g) 0.5 0.5 0.5 0.5 50% glycerin (mL) — 6.0 — — Methylcellulose (g) — — 0.1 — Tragacanth (g) — — — 0.1 Distilled water to (mL) 10 10 10 10 3.1.2 Procedures (a) Preparation of formulation 1 and 2 Weigh the designated amount of zinc oxide and transfer it to a mortar. Add 0.3 mL of distilled water or glycerin and levigate the mixture to form a paste. Add the remaining glycerin and continue mixing. Further dilute the suspension with 80% of the remaining distilled water, transfer the suspension to a 10 mL graduate cylinder, and add distilled water to volume (10 mL). 3 Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I (b) Preparation of formulation 3 Weigh 0.1 g of methylcellulose and transfer to a mortar. Add distilled water and mix until a solution is formed. To this solution, add zinc oxide and levigate to form a paste. Add 80% of the remaining distilled water and continue mixing until a uniform suspension is formed. Transfer the suspension to a 10 mL graduate cylinder and add distilled water to volume (10 mL). (c) Preparation of formulation 4 Weigh 0.1 g of tragacanth, transfer to a mortar, and then add several drops of alcohol as the wetting agent. Add a small amount of distilled water to the mixture and levigate to form a paste. Add zinc oxide and follow the procedures as described in (b). (d) Measurement of sedimentation volume Agitate the four suspensions contained in the stoppered graduate cylinders by turning it upside down for five times and let the samples stand. Measure the height of the sediments (mL) at 1, 5, 10, 30, 60, 90 and 120 min after shaking and calculate the sedimentation volume. Record the results in Table 3 and plot the sedimentation volume vs. different formulations. 3.1.3 Experimental notes a) When preparing the suspension, keep the volume of the solution added, time of mixing, and intensity of levigation the same for all formulations evaluated in this experiment. b) Use stoppered graduate cylinders with the same diameter for the measurement of sedimentation volume. c) The mortar should be rinsed with a small amount of distilled water to achieve complete transfer of the suspension into the graduate cylinder. 3.2 Influence of flocculating agents on the redispersion of suspensions 3.2.1 Formulations (1) 1.0 g Bismuth subnitrate (碱式硝酸铋) Distilled water, q.s. 10 mL (2) Bismuth subnitrate 1% sodium citrate solution Distilled water q.s. 3.2.2 Procedures (a) Preparation of suspensions 4 1.0 g 1.0 mL 10 mL Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I Weigh 2.0 g of Bismuch subnitrate and transfer to a mortar. Add 0.5 mL of distilled water and levigate to form a paste. Add the remaining distilled water in small portions and mix to give a uniform suspension. Tranfer the suspension into a 10 mL graduate cylinder. After shaking, divide the suspension into two equal parts. One part is diluted with distilled water to 10 mL as formulation (1). To the second part, 4 mL of distilled water and 1.0 mL of 1% sodium citrate solution are added to give formulation (2). Shake both suspensions in the graduate cylinders and let the samples stand for 2 hours prior to evaluations. (b) Examine the appearance of the sediment Visually examine the suspension with respect to the appearance of the supernatant and sediment. Turn the graduate cylinder upside down and observe the ease of redispersion of the sediment. Record the state of redispersion of the sediment as a function of the number of upside down turns of the graduate cylinder. (c) Experimental notes When shaking the graduate cylinders upside down, use the same intensity and avoid vigorous shaking since this many obscure the subtle different in dispersion state of the suspension. 3.3. Preparation of suspensions with hydrophobic drugs and comparison of different wetting agents. 3.3. 1 Formulations The composition of different sulfur suspensions are listed in Table 2. 3.3.2 Procedures Weigh 0.2 g of refined sulfur and transfer in a mortar. Add the appropriate amount of distilled water, alcohol, glycerin, soft soap or Tween 80 (with small amount of distilled water) and levigate. Add the remaining amounts of distilled water by small portions and mixed until a uniform suspension is formed. After shaking, note the dispersion state of the sulfur particles and record the observation. Table 2. Composition of different sulfur suspensions No 1 2 3 Refined sulfur (g) 0.2 0.2 0.2 4 0.2 Alcohol (mL) 50% glycerin (mL) Soft soap (mL) — — — 2.0 2.0 — — — 1 — — — Tween-80(g) Distilled water to (mL) — 10 — 10 — 10 0.03 10 5 Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I 3.3.3 Experimental notes (a) Weigh the same amount of the sulfur for all formulations in order to ensure meaningful measurement for comparison purposes. (b) The suspension prepared in the mortar should be transferred to the graduate cylinders without any loss. 3.4 Preparation of the sulfur suspension by coaggregation method Add 5 mL of 4%(W/V)hydrochloric acid and 5 mL of 20%(W/V)hyposulphite in a 10 mL graduated cylinder. After shaking, observe the dispersion state of the sulfur and record your observation. . 4. RESULTS AND DISCUSSION 4.1 Fill in the sedimentation volume results in Table 3. Table 3. The change in sedimentation volume as a function of time Time Formulation No. (min) 1 2 3 4 Hu Hu/H0 Hu Hu/H0 Hu Hu/H0 Hu Hu/H0 5 10 30 60 90 120 Note:H0 is the height of suspension;Hu is the height of the sediment. 4.2 Based on the data in Table 3, plot the sedimentation curve using Hu/H0 as the Y-axis and time as the X axis and compare the suspending capacity of different suspending agents. 4.3 Record the appearance of the supernatant and sediment of the Bismuth subnitrate suspensions 2 hours after preparation and the numbers of upside down turn required to resuspend the sediment. 4.4 Record the appearance of the supernatant and sediment of different sulfur suspensions and discuss the stabilizing effect of different wetting agents. 4.5 Record the appearance of the supernatant and sediment of the sulfur suspensions prepared by the dispersing method and that prepared by the coaggregation method. Discuss the impact of preparation methods on the dispersion state and physical stability of the suspensions. 6 Shenyang Pharmaceutical University LAB 1: SUSPENSIONS PHARMACEUTICS I 5. QUESTIONS a) Explain the differences between zinc oxide suspension and sulfur suspension with respect to their formulation and method of preparation. b) To improve the stability of the following formulation, what stabilizers should you select? Please describe the function of each ingredient in the formulation and the method of preparation. Formulation Zinc oxide 6.0 g Liquid phenol 1.0 mL Glycerin 2.0 mL Limewater q.s. Total 100 mL c) What is the difference between a suspension prepared by the dispersing method and that prepared by the coaggregation method in terms of product appearance and physical stability ? References [1] H. C. Ansel, N. G. Popovich and L. V. Allen, Jr. Pharmaceutical Dosage Forms and Drug Delivery Systems, 8th ed., Williams and Wilkins, Baltimore, 2005. [2] M.E. Aulton. Pharmaceutics: The science of dosage form design. 1988. (Shirui MAO) 7