Experiment: Dry Oxidation

advertisement

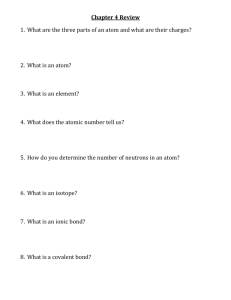

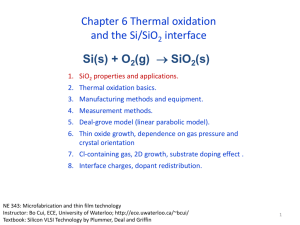

Experiment 1: Dry Oxidation (SiO2) Process Objective: 1. To understand the basic principle of dry oxidation process. 2. To determine the growth rate of the oxide. Introduction Oxidation is one of the most important thermal processes. It is an adding process, which adds oxygen to a silicon wafer to form silicon dioxide to a silicon surface. Oxidation reaction occurs on the surface of silicon when in contact with oxygen. Initially, the reaction occurs quickly, however as the oxide layer on the surface grow, the oxygen must diffuse through the oxide before it reaches the silicon and reacts. The diffusion of the oxygen (or water vapor) is the oxidation rate-determining factor. The oxidation rate is controlled by four conditions: temperature, pressure, humidity, and crystal orientation. Generally, the crystal orientation of the surface determines how many silicon atoms are exposed to oxygen in order for initial reaction to occur. The closest packed plane, in case of silicon is (111) will react fastest because it has the most atoms on the surface. Increased humidity increases the reaction rate. In this study, we used the <100> orientation silicon wafer. The oxidation process can be carried out through wet or dry conditions. Dry oxidation simply flow oxygen gas over the silicon and the reaction that occurs is: Si + O2 SiO2 Wet condition produces the fastest reaction rate. Wet condition can be developed by flowing oxygen through water so the oxygen carries it with water vapor. The reaction that occurs is: Si + 2H2O SiO2 + 2H2 The reaction of pure oxygen occurs simultaneously with the reaction with water vapor; however the latter occurs much more rapidly and causes the reaction with pure oxygen to become insignificant. Equipment / Chemicals i. Gas N2 and O2 ii. Quartz boat iii. Quartz Rod iv. Timer v. Wet Oxidation Furnace vi. Spectrophotometer vii. Four point probe viii. Optical Microscope Methodology Parameter List down all the parameters and settings Temperature, T = 1000°C N2 level = 1l/min O2 level = 1l/min Oxidation Time = 30 min 1. Turn on furnace. Ramp up to T = 500°C 2. Scribe wafer accordingly. 3. Load 2 wafers into furnace tube. 4. Start N2 flow for purging. 5. Set the temperature. 6. When T reaches the temperature, slowly open O2 valve and close N2 valve. 7. Start the timer. 8. Run oxidation process for desired time, e.g. t = 30 min. 9. When oxidation complete, close O2 valve, open N2 valve. 10. Ramp down the furnace to T = 500°C 11. Unload and cool the wafer to the ambient temperature. 12. Close N2 valve. 13. Measure and record the oxide thickness in Table 2.3.1. Take at least 5 readings at different point. 14. Observe wafer under optical microscope. Characterization/Testing 1. Thickness measurement 2. Particle/defect/color inspection Results Table 2.3.1: Wet Oxidation Oxidation time: 30 min 1 2 3 4 5 Thickness, A Colour Oxidation time, t n = __________ min Initial oxide thickness, OxTi = __________ Å After oxide thickness, O x Tn = __________ Å Growth rate, OGR = OxTn OxTi = ___________ Å/min tn Discussion 1. Calculate the growth rate of the oxidation process. Avg Std Uni 2. Why Hydrofluoric dip is necessary before oxide growth? 3. What are the parameters affecting oxidation rate? 4. Recognize the colour different of the oxide after each etching steps. Use colour code to estimate the oxide thickness and compare the result with spectrophotometer measurement. 5. What are the advantages and disadvantages of wet oxidation over dry oxidation? Conclusion Based on your understanding, please conclude the experiment result. Reference 1. 2. http://www.guajara.com/wiki/en/wikipedia/e/el/electrical_resistivity.html Peter Van Zant. 2000. Microchip Fabrication: A Practical Guide to Semiconductor Processing 4th Edition. McGraw Hill Co.