AIM - Monash University

advertisement

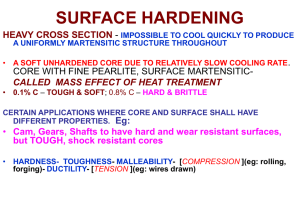

MONASH UNIVERSITY Department of Materials Engineering PRECIPITATION HARDENING OF Al-4Cu EXPERIMENT T9 AIM To demonstrate the change in microstructure and in tensile properties associated with the ageing of a precipitation hardening alloy - in particular, of Al-4 wt.% Cu. REFERENCES J.M. Silcock, T.J. Heal, H.K. Hardy, J. Inst. Metals, 82, 1953, p. 239. R.E. Smallman, "Modern Physical Metallurgy", Butterworths. J.W. Martin, “Precipitation Hardening”, 2nd Edn., Butterworth-Heinemann, 1998. D.A. Porter and K.E. Easterling, "Phase Transformations in Metals and Alloys", 2nd Edn., Chapman & Hall, 1993, pp 291-308. INTRODUCTION Structural features The sequence of precipitation in Al-Cu alloys depends on the degree of supersaturation of copper and the ageing temperature. When the copper content is high and ageing temperature is low, the sequence is: (i) G.P. Zones - discs of nearly pure copper on (100)Al, one atom plane thick and of the order of 10 nm diameter. (ii) " - coherent precipitates of the order of a few nm thick and 150 nm diameter. The structure is tetragonal and the composition is already CuA12. (iii) ' - coherent precipitates which only have weak long range strain fields since each precipitate is associated with a dislocation loop. (iv) - this is the equilibrium CuAl2 precipitate. Its structure is yet another tetragonal one and it is commonly regarded as incoherent. At sufficiently high temperatures or low copper content the sequence is only ' The limiting temperatures at which various intermediate phases can be found are March, 2007 conveniently indicated on a "metastable phase diagram" as, for example, a "G.P. zone solvus". The rate of precipitation is governed by the rates of diffusion. These in turn, are sensitive to the vacancy super-saturation, lattice strain and impurities. The last two of these are a function of the solution treatment temperature and the quench rate. Strengthening mechanisms In general, precipitates may be deformable or non-deformable. In the first case, the strength of the alloy depends on the structure and properties of the precipitate, whereas in the second case, the strength is controlled by the inter-particle spacing. Features of the precipitate which may be important to strength are: (a) coherency strains (b) order-disorder energies (c) differences in modulus between particle and matrix, and (d) chemical hardening due to the energy of newly created particle-matrix interface. The deformation mechanism has a marked effect on the work-hardening rate. If particles are cut by dislocations, then slip is planar and work-hardening slight: conversely, bypassing of particles causes turbulent slip and strong work-hardening. In the Al-Cu system, GP zones and " are generally deformable. The important feature contributing to strength is probably chemical hardening ((d) above). Small ' precipitates may also deform, but thicker ' are not cut by dislocations. usually precipitates in such a dispersion that it, too, is not cut by dislocations. The full precipitation sequence (i.e. at low ageing temperatures) gives rise to a threestage hardening sequence: hardening due to GP zones, additional hardening due to " followed by softening as ' and form. At higher temperatures, only ' and occur: there is then initial hardening due to the fine initial dispersion of ' followed by softening as the ' coarsens: also appears at or after peak hardness. EXPERIMENTAL PROCEDURE Examine the four transmission electron micrographs of Al-4%Cu, quenched from 525°C and aged at 160°C and 190°C for various times. Describe and comment on the March, 2007 microstructures shown in the micrographs provided. You are provided with 5 tensile samples of the same alloy, quenched from 525°C and aged for various times at 200°C as indicated. Prepare the as-quenched sample and a sample aged at 200°C for a time between 5-20 min., as determined by the group. (a) Measure the hardness of these samples using the Vickers hardness tester. Make five indents in each of the samples, average the readings and determine the hardness. Plot Vickers hardness number (VHN) vs (log) ageing time. (b) Electropolish the tensile samples in Lenoir’s solution Protect your eyes by wearing safety glasses. Wash your hands immediately with cold water if the solution comes into contact with your skin. (c) Wear gloves. Test the samples in the Instron machine to a strain of 10% using a load cell of 5 kN and speed of 5mm/min. Record the 0.2% proof stress and the initial rate of work hardening. Examine the surfaces of the deformed specimens with a microscope and make sketches of the main features you see. Using the tensile stress-strain curves obtained, plot (i)0.2% proof stress and (ii) initial work hardening rate vs (log) ageing time. Wear safety glasses to protect your eyes. Keep your hands away from the moving parts of the machine. (d) Continue the tests to failure and record the tensile strength and elongation to fracture. Plot tensile strength and elongation to failure vs (log) ageing time. REPORT Write a report of approximately 2000-3000 words with emphasis on the link between the precipitate microstructures, strengthening mechanisms and the measured March, 2007 mechanical properties. It worth 6% of total mark for the unit. ASSESSMENT Reports will be assessed both for technical content and for technical communication skills. March, 2007