Heat Treatment 1 ex 5

advertisement

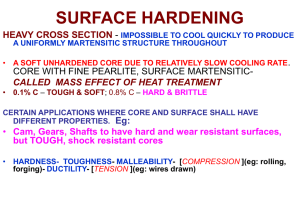

Motivation Stapler (~HK$ 5) Approx. 15 components - How do we select the best material for each component? - How are each of these manufactured? Car: ~ 15,000 parts; Boeing 747 plane: ~6 million parts Intel core 2 duo processor: 65 nm feature size, 291 million transistors Properties of materials Steels are heat treated for one of the following reasons: Mechanical properties of materials Strength, Toughness, Hardness, Ductility, Elasticity, Fatigue and Creep Physical properties Density, Specific heat, Melting and boiling point, Thermal expansion and conductivity, Electrical and magnetic properties Chemical properties Oxidation, Corrosion, Flammability, Toxicity, … Materials Ferrous metals: carbon-, alloy-, stainless-, tool-and-die steels Non-ferrous metals: aluminum, magnesium, copper, nickel, titanium, super alloys, refractory metals, beryllium, zirconium, low-melting alloys, gold, silver, platinum, … Plastics: thermoplastics (acrylic, nylon, polyethylene, ABS,…) thermosets (epoxies, Polymides, Phenolics, …) elastomers (rubbers, silicones, polyurethanes, …) Ceramics, Glasses, Graphite, Diamond, Cubic Boron Nitride Composites: reinforced plastics, metal-, ceramic matrix composites Nanomaterials, shape-memory alloys, superconductors, … Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat Treatment is often associated with increasing the strength of material, but it can also be used to alter certain manufacturability objectives such as improve machining, improve formability, restore ductility. Heat Treatment A: Definition "Hardening is the process of heating a piece of steel to a temperature within or above its critical range and than cooling it rapidly" (Begeman, M.L. - Manufacturing processes - 1977) B: Definition "Hardening is that property of a material that enables it to resist plastic deformation, penetration, indentation, scratching" (Lindberg, R. A. - Material & Manufacturing Technology 1968) Hardening: Hardening of steel is done to increase the strenth and wear properties. One of the pre- requisites for hardening is sufficient carbon and alloy content Softening: Softening is done to reduce strength or hardness, remove residual stresses, improve tough-ness, restore ductility, refine grain size or change the electromagnetic properties of the steel. Material Modification: Heat treatment is used to modify properties of materials in addition to hardening and softening. These processes modify the behavior of the steels in a beneficial manner to maximize service life, e.g., stress relieving Tempering Tempering is a process done subsequent to quench hardening. Quench-hardened parts are often too brittle. This brittleness is removed by tempering. Tempering results in a desired combination of: Hardness, Ductility, Toughness, Strength, structural stability QUENCHING Cooling alloy fast enough to retain a supersaturated solid solution of alloying constituents without introducing adverse metallurgical or mechanical conditions; water is most common quenching media (immersion or spray); other media include air blasts, soap solutions, ind hot oil. HARDNESS TESTING ROCKWELL TEST Measures the difference in penetration between a minor and major load Minor load 10 Kg Major load 60(a), 100 (B), 150 ( c) kg A= Diamond, B= 1/16 in. ball, C= diamond Rockwell scale runs to 130 bur only useful in range 20 -100 SURFACE HARDENING l. Carburizing or Case Hardening Steel is heated in contact with some carbonaceous material in solid, liquid, or gas form; the steel absorbs carbon, which is gradually diffused into the interior of the part. Pack carburizing (.030 to .160 thick); it employs packing parts in charcoal or coke. Gas carburizing (.005 to .030 thick); it employs hydrocarbon fuels. Liquid carburizing (up to .250 thick); it employs a cyanide salt bath FLAME HARDENING: Heating by oxyacetylene flame to above critical temperature; heated part immediately quenched by water spray; produces hard surface with ductile backing.