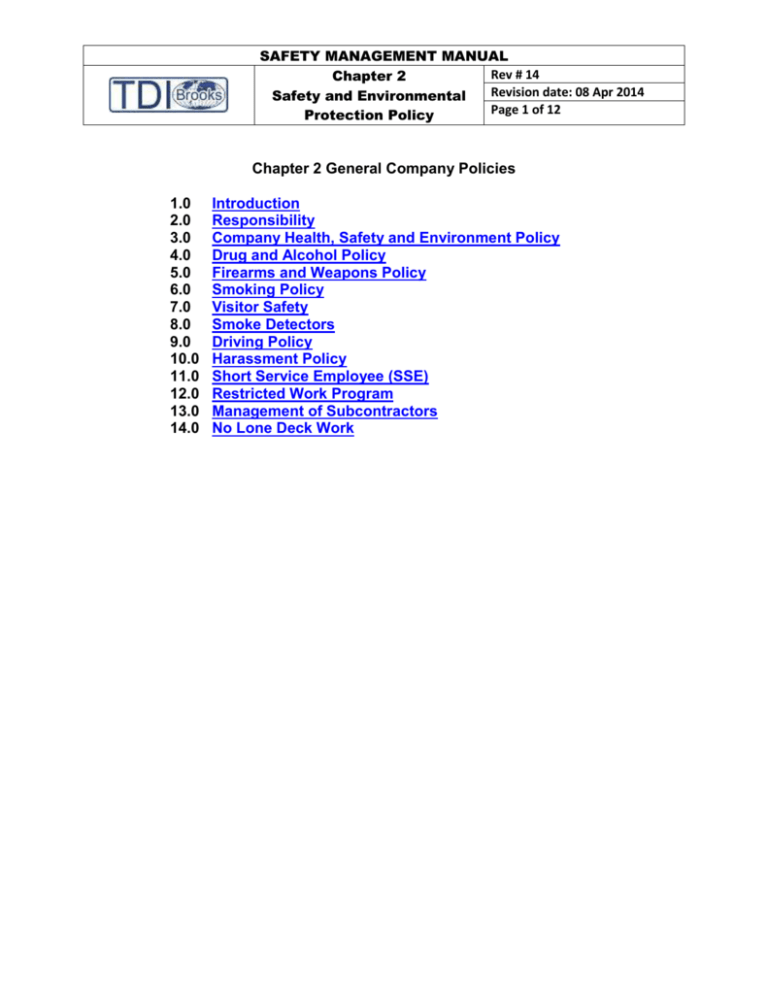

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 1 of 12

Protection Policy

Chapter 2 General Company Policies

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

Introduction

Responsibility

Company Health, Safety and Environment Policy

Drug and Alcohol Policy

Firearms and Weapons Policy

Smoking Policy

Visitor Safety

Smoke Detectors

Driving Policy

Harassment Policy

Short Service Employee (SSE)

Restricted Work Program

Management of Subcontractors

No Lone Deck Work

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 2 of 12

Protection Policy

Revision/ Review Log

Revision Date

Approved by

Reviewed by

11 January 2010

Dr. Jim Brooks

HSE Manager:

Sue McDonald

Dr. Jim Brooks

Dr. Bernie Bernard

HSE Manager:

Russell Putt

Dr. Jim Brooks

Dr. Bernie Bernard

Port Captain:

Capt. Pat Fallwell

Dr. Jim Brooks

Dr. Bernie Bernard

Dr. Jim Brooks

Dr. Bernie Bernard

Dr. Jim Brooks

Dr. Bernie Bernard

Goal of zero accidents and no

harm to personnel or environment

added to HSE statement

Dr. Jim Brooks

Dr. Bernie Bernard

Dr. Jim Brooks

Dr. Roger Fay

Capt. Pat Fallwell

Reasonable cause testing form to

be completed before testing

Dr. Jim Brooks

Dr. Bernie Bernard

Dr. Jim Brooks

Dr. Roger Fay

Capt. Pat Fallwell

Dr. Jim Brooks

Ms. Gail Mills

Ms. Kathleen Nease

Dr. Jim Brooks

Mr. Pete Tatro

Dr. James Howell

Dr. Jim Brooks

Mr. Pete Tatro

Dr. James Howell

Annual drug test requirement

removed, random testing for all

employees, including non-US

citizens

Drug and alcohol policies in

Employee Manual and SMM

merged. All new and offshore

employees must sign an

acknowledgement and release of

drug and alcohol testing results

No one may work alone on deck

Dr. Jim Brooks

Mr. Pete Tatro

Dr. Jim Brooks

Mr. Pete Tatro

Charlie Emerson

Drug and alcohol policy modified

to incorporate Vanuatu

requirements

Dr. Jim Brooks

Mr. Pete Tatro

Dr. Jim Brooks

Mr. Pete Tatro

Bloodborne pathogens moved to

new SOP

Revision #5

15 October 2010

Revision Details/ Proposal

Notes

Changed to electronic format

Revision #6

20 May 2011

Revision #7

12 Aug 2011

Revision #8

03 May 2012

Revision #9

03 May 2012

Revision #10

27 August 2012

Revision #11

12 February 2014

Revision #12

28 March 2014

Revision #13

08 April 2014

Revision #14

Bloodborne pathogens and

subcontractor evaluation sections

added.

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 3 of 12

Protection Policy

1.0

Introduction

This chapter describes Company policies for TDI-Brooks’ vessels. These vessels

operate in compliance with applicable international, Vanuatu and U.S. Coast Guard

guidelines as well as best practices.

2.0

Responsibility

The president of TDI-Brooks is ultimately responsible for the safety, and health of his

employees and the protection of the environment. All managers and supervisors must

take an active role in TDI-Brooks’ safety and environmental programs by initiating

preventive measures to control hazards associated with TDI-Brooks activities. However,

safety is the responsibility of all TDI-Brooks employees.

3.0

Company Health, Safety, and Environment Policy (HSE)

TDI-Brooks is committed to providing its employees, contractors, clients, and visitors a

safe environment in which to work. TDI-Brooks is also committed to the protection of the

environment and strives to meet environmental compliance (see the following policy

statement).

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 4 of 12

Protection Policy

TDI-Brooks International’s

Commitment to the Health and Safety of Employees

and Protection of the Environment

It is the goal of TDI-Brooks International to conduct each project with zero accidents and no

harm to personnel or the environment.

TDI-Brooks International is committed to providing its employees, contractors, clients, and

visitors a safe environment in which to work. Safety is the business and responsibility of every

employee and can be better achieved through proper engineering, education, training, protective

equipment, and enforcement of safety rules. TDI-Brooks International is responsible for providing the

proper equipment, tools, training, supervision, and policies to their employees to meet the Company’s

commitment to a safe work environment. Every employee is responsible for understanding and

practicing appropriate safety procedures for their own protection, as well as others. TDI-Brooks

International is also committed to the protection of the environment.

In order to meet this commitment, TDI-Brooks International follows U.S. and international

standards and fosters an attitude consistent with the goals of safe and healthy operations, as well as

environmental preservation. TDI-Brooks International also maintains a Health, Safety and

Environment (HSE) system within its organization. The HSE system includes extensive policy and

guideline documentation based on industry standard guidelines, training opportunities, adequate

equipment and supplies, and trained HSE personnel. The main objectives of the HSE system include:

safety and loss prevention; mitigating occupational hazards; trained personnel; ensuring that

employees are provided with appropriate personal protective equipment (PPE); a safe, comfortable

working environment; negligible adverse environmental impact; and a system of investigating

accidents and taking corrective actions.

TDI-Brooks International also has a strict “zero tolerance” policy for the possession or use of

any controlled substance, as well as alcohol, while aboard their vessels. The Company has a

drug/alcohol-testing program that includes random testing.

TDI-Brooks International is committed to providing a safe working environment for its

employees, contractors, and clients. We are open to comments and suggestions from our employees,

contractors, and clients in order to improve our HSE system. The HSE system is designed to be

flexible in order to meet the needs of our employees, contractors, and clients.

President

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 5 of 12

Protection Policy

4.0

Drug and Alcohol Policy

It is the policy of this company to maintain a work environment that is safe for employees and

conducive to attaining high work standards. As part of this policy, no intoxicating beverages,

illegal drugs, paraphernalia or equipment related to illegal drug use are allowed aboard vessels,

in offices or other work locations of the company.

In accordance with U.S. Coast Guard and the Vanuatu Administration, TDI-Brooks has a "ZERO

TOLERANCE" for possession or use of any illegal drugs. The policies of these organizations are

very similar. In instances where they overlap, the stricter of the two shall apply.

TDI-Brooks International prohibits alcohol/ illegal drug possession and consumption while

onboard a vessel. Any crewman or other TDI-Brooks employee found in possession of alcohol/

illegal drugs is subject to immediate termination.

4.1 Definitions

Chemical Test- means a scientifically recognized test, which analyzes an individual’s

breath, blood, urine, saliva, bodily fluids, or tissues for evidence of dangerous drug or

alcohol use.

Crew member- means an individual who is on board a vessel acting under the authority

of a license, certificate of Registry, or merchant mariner’s document issued by the flag

state.

Dangerous Drug- means a narcotic drug, controlled substance, and marijuana.

Non-crew member- scientific personnel, surveyors and all personnel not required to

hold an STCW certificate who are working on board the vessel.

4.2 Pre-Employment and Random Testing

Crew members and all other TDI-Brooks employees are required to pass a pre-employment

drug and alcohol test before working offshore.

Crew members and all other TDI-Brooks employees are subject to random testing based on the

flag state requirements. The current testing rates of 25% of crew for US flagged vessels will

be increased to match the 50% rate for Vanuatu flagged vessels. Random testing will be

done by geographic locations of the vessel operations using appropriate random selections

methods. (VMB #115 Sec 2.2)

4.3 Reasonable Cause Testing

Reasonable cause testing will be undertaken whenever a supervisor determines that there is a

reasonable cause to believe that an employee is under the influence of drugs or alcohol. The

supervisor will base their decision on physical, behavioral, and performance issues. Any nearmisses, accidents, or suspicious behavior can trigger a drug and alcohol test.

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 6 of 12

Protection Policy

The employee’s direct supervisor will complete the Reasonable Cause Testing form before the

test is performed. The Reasonable Cause Testing form is located on the ship web pages on the

SMM Forms Only page.

The fact that a reasonable cause test was conducted and any refusals to test must be

entered into the vessel’s official logbook. If an employee refuses to comply with reasonable

cause testing, that employee will be immediately removed from any safety sensitive position and

may face termination.

If the crew/vessel is in a location that an employee cannot be transported to an approved clinic

or hospital for testing, reasonable cause testing may be conducted aboard the vessel and must

be administered by a DOT certified collector. However, the testing may not be conducted by the

person requesting it. Shore based employees will be transported to the nearest approved

testing facility.

The HSE Manager is responsible for decisions regarding drug and alcohol testing policies and

procedures. On vessels at sea, the Party Chief or the HSE Officer on board may make the

decision whether or not to conduct offshore testing for reasonable cause.

The Designated Employee Representative of TDI-Brooks is responsible for managing drug and

alcohol testing for all TDI-Brooks employees. Any reasonable cause testing will be reported to

the DER and upper management as soon as possible. TDI-Brooks has contracted the services

of an off-site Medical Review Officer to review all drug test results.

4.4

If a Drug Test is Positive

Vanuatu Administration’s drug and alcohol policy is documented in the following:

Vanuatu Maritime Act CAP 131 Sec 137 Drunkenness, Neglect of Duty

Vanuatu Shipping Articles Item 12 Possession of dangerous weapons, narcotics,

contraband articles or alcoholic beverages

Vanuatu Maritime Bulletin (VMB) #115 Use of Drug Testing Consortiums for

Mandatory Testing

If the results of a drug test for a crew member are verified positive, the employee will be

immediately removed from performing safety-sensitive functions and may not return to safety

sensitive functions without completing the return to duty process.

Return to Duty:

USA- 49 CFR Part 40.23(a) and 40.305

Vanuatu- VMB #115 Sec 2.5

The positive results of crew members must be reported to the appropriate Maritime

Administration. If an MRO verifies a lab confirmed positive report, the MRO shall report the

positive test result to the vessel operator and to Vanuatu Maritime Services Ltd. (VMB #115 Sec

3.2)

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 7 of 12

Protection Policy

The employer is responsible for reporting positive results of crew members to the USCG. (46

CFR Part 16 16.201(c)).

4.5 Searches

Entry into or upon any vessel, office or other work location of the company is conditioned upon

the company's right to search the person, personal effects and vehicle of any entrant for illegal

drugs, intoxicating beverages, firearms, or possession of unauthorized property or equipment.

From time to time and without prior warning, searches by authorized company representatives

may be made of anyone entering or on company premises, including vessels, or company

vehicles and such searches may be made of employees as well as employees of contractors

having business with the company. This search may include lockers and rooms if appropriate.

Searches on US Flagged vessels are conducted according to 33 CFR 104.265(e)(2) and 33

CFR 105(e)(2).

When appropriate, such items discovered through these company searches may be taken into

custody and may be turned over to the proper authorities. Violation of the above policy or

refusal to submit to a search will be cause for disciplinary action up to and including immediate

termination.

4.6 Testing Facilities

Only certified facilities will be used to analyze all drug and alcohol tests. Should a test need to

be administered in a foreign country, every effort will be made to assure that standard chain-ofcustody protocols are followed to ensure the integrity of the tests.

4.7 Acknowledgement and Release Form

All employees who work offshore are required to sign a copy of the Acknowledgement and

Release Form regarding the Drug and Alcohol Policy as a condition of employment.

4.8

Resources for Rehabilitation

At request of the employee, information on resources may be provided for the recovery of drug

and alcohol abuse. Please contact the Quality Management Representative if you are interested

in these resources.

5.0

Firearms and Weapons Policy

Firearms or any other type of weapons are not permitted aboard the vessel. The exception to

this policy is if the vessel is in a region of the world that the threat of violence necessitates the

presence of armed guards.

6.0

Smoking Policy

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 8 of 12

Protection Policy

Smoking is permitted only in designated exterior areas. The Master defines the designated

areas. Smoking is not permitted in the interior of the vessel.

7.0

Visitor Safety

No visitors are permitted on the vessel without permission of the Master or officer on watch. All

visitors will receive a safety orientation, vessel tour, and an identification badge.

Visitors are not permitted to roam about the vessel without an escort.

8.0

Smoke Detectors

Tampering with smoke detectors on the vessel is not permitted. Doing so may result in

immediate dismissal.

9.0

Driving Policy

All drivers operating a vehicle for TDI-Brooks business must have a valid driver license and

obey state, county, and city traffic regulations. Drivers also shall not abuse the vehicle. They

should plan trips so that appropriate schedules can be maintained, exhibit courtesy in all driving

operations, yield right-of-way when in doubt, and keep right to allow faster traffic to pass.

Supervisors shall not schedule runs nor permit or require the operations of any motor vehicle

between locations in such a period of time that will require the vehicle to be operated at speeds

greater than those prescribed by the laws in the area in which the vehicle is being operated. The

following are the Company’s driving policies and apply to company vehicles and personal

vehicles used for company business.

Only company employees or persons authorized by the supervisor will be permitted to

ride in TDI-Brooks vehicles.

All state, local, and company speed limits shall be observed when operating a

company vehicle.

Regardless of legal speed limits, company vehicles may not exceed the posted limits

or the following maximum speed limits:

o Interstate and state highways, 65 mph or legal limit

o County highways, 55 mph or legal limit

o Gravel or dirt roads, 45 mph

The driver and passengers must use seat belts when in company vehicles.

Drivers will not drive under the influence of alcohol, illegal drugs, or legal drugs that

impair alertness.

Alcohol, illegal drugs, firearms, or contraband items are not permitted in company

vehicles.

The use of cell phones while driving is not permitted. Safely pull off the road to talk on cell

phones.

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 9 of 12

Protection Policy

10.0

Harassment Policy

It is the Company’s position that employees should be able to work in an environment free of

sexual harassment. Sexual harassment is a form of misconduct that undermines the

employment relationship. No employee, either male or female, should be subjected verbally or

physically to unsolicited and unwelcome sexual overtures or conduct.

Sexual harassment refers to behavior that is not welcome, personally offensive, and debilitates.

Behavior that amounts to sexual harassment will result in disciplinary action, including

dismissal.

10.1

Definition

TDI-Brooks has adopted, and its policy is based on, the definition of sexual harassment set forth

by the Equal Employment Opportunity Commission (EEOC). The EEOC defines sexual

harassment as unwelcome sexual advances, requests for sexual favors, and other verbal or

physical conduct of a sexual nature when:

Submission to such conduct is made either explicitly or implicitly a term or condition of

your employment;

Submission to or rejection of such conduct by you is used as the basis for employment

decisions affecting you; and /or

Such conduct has the purpose or effect of unreasonably interfering with your work

performance or creating an intimidating, hostile, or offensive working environment.

10.2

Company’s Responsibility

TDI-Brooks wants its employees to have a work environment free of sexual harassment by

management personnel, coworkers, and others with whom an employee must interact in the

course of their work. Sexual harassment is specifically prohibited as unlawful and as a violation

of Company policy. TDI-Brooks is responsible for preventing sexual harassment in the

workplace, taking immediate corrective action to stop sexual harassment in the workplace, and

promptly investigating any allegation of work-related sexual harassment.

10.3

Compliant Procedure

Any suspicions of sexual harassment in the workplace should be reported immediately to the

HSE Manager or to any other member of the Company’s management. All allegations of sexual

harassment will be quickly investigated. Confidentiality of all individuals involved will be

protected against unnecessary disclosure. When the investigation has been completed, the

affected employees will be informed of the outcome of that investigation.

10.4

Retaliation Prohibited

TDI-Brooks will permit no employment-based retaliation against anyone who brings a complaint

of sexual harassment or who speaks as a witness in the investigation of a complaint of sexual

harassment.

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 10 of 12

Protection Policy

11.0

Short-Service Employee (SSE)

Due to the nature of the work undertaken by TDI-Brooks, short-service employees (SSEs) are

frequently hired based upon the needs of a particular work effort. Consequently, TDI-Brooks has

developed a Short Work Service Program to address the issues associated with the safety and

health of SSEs. This program assures that SSEs receive the necessary training that will ensure

their health and safety, as well as the health and safety of those working with SSEs.

An SSE is an individual who (1) has not worked more than six (6) months of service with

TDI-Brooks or (2) has not worked more than twelve (12) months of appropriate

experience that ended within the previous 12 months.

The TDI-Brooks SSE program includes the following:

An SSE will work with a qualified mentor (a current employee who is fully trained and

qualified with respect to their job and HSE issues). This mentor will ensure that the

SSE is only performing tasks for which they have received the proper training.

The mentor and a supervisor will evaluate the performance and progress of the SSE

and decide when the SSE is fully qualified for the job.

An SSE will be clearly identified to the crew, either by wearing a different colored hard

hat or a hard hat that is marked to differentiate him as a SSE in PPE required zones.

SSE personnel are required to attend and participate in the TDI-Brooks orientation

program described in Section 6.4 of this document.

SSE personnel will also receive training required by all crew members on the vessel

(i.e., Sea Survival Training, basic first aid and CPR).

SSE personnel will not be assigned supervisory duties or placed in a safety sensitive

position until adequate training and experience has been achieved.

An employee designated as an SSE will remain so for a minimum of six (6) months,

depending upon the nature of the job and individual performance.

12.0

Restricted Work Program

TDI-Brooks’ policy is to assure its employees that every effort will be made to protect their

employment should they suffer an illness or injury. This policy will make provisions with injured

or ill employees so that they can either work in their original position on a modified schedule or

an alternate position with the same restrictions to their work hours, volume, and /or tasks. An

injured/ill employee will be allowed to participate in a modified or alternate work program for

seven (7) days. After the initial seven (7) day period, a seven (7) day extension may be

requested in writing to the vessel’s HSE representative or the TDI-Brooks HSE Manager.

As defined in this manual, modified or alternate work duty is: Any job, task or function or some

combination which are meaningful and productive and can be performed by a worker who has

suffered from a diminished capacity, temporarily or permanently due to a work related accident,

and without risk or re-injury to themselves or others.

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 11 of 12

Protection Policy

13.0

Management of Subcontractors

The purpose of this policy is to provide guidance on HSE requirements to sub-contractors.

A sub-contractor who works on TDI-Brooks’ property or under TDI-Brooks’ prevailing influence

must conduct their activities in a manner that is consistent with safe, healthy, and

environmentally friendly operating practices and in accordance with all the applicable health,

safety, and environmental rules and regulations.

This policy applies to all sub-contractors who are expected to perform work or provide services

for TDI-Brooks.

13.1

Requirements

The HSE program and record of each sub-contractor will be considered by TDI-Brooks’ during

the selection process. At TDI-Brooks’ request, subcontractors may be required to provide their

current HSE incident rates and/or other information as determined. It is the primary

responsibility of each sub-contractor to provide a safe and healthy workplace for their

employees. All sub-contractors must perform their work in accordance with all applicable local

and national government regulations, as well as with the HSE policies and procedures of TDIBrooks or TDI-Brooks’ clients. All sub-contractors will provide their employees with appropriate

medical examinations, drug screening, personal protective equipment (PPE), and survival at

sea training before beginning work.

All sub-contractors are responsible for ensuring that their equipment is in proper working

condition and that any unsafe conditions will be corrected as soon as possible.

All sub-contractors will conduct safety meetings for their employees or have their employees

attend TDI-Brooks safety meetings, as well as monitor their work activities to help ensure safe

working practices and conditions. The sub-contractor must document each safety meeting,

stating the time, place, and subject discussed, and include each employee’s signature. All subcontractors will notify a TDI-Brooks supervisor immediately about all accidents involving their

employees on TDI-Brooks’ property or under TDI-Brooks’ prevailing influence. All subcontractors will comply with TDI-Brooks’ alcohol and drug policy when performing work for TDIBrooks or its clients. All sub-contractors must comply with TDI-Brooks’ policy for sub-contractors

and communicate it to their employees.

TDI-Brooks reserves the right to audit/ inspect the sub-contractors’ HSE program,

equipment, and operations before and during performance of the work.

13.2 Subcontractor Evaluation

TDI-Brooks International will evaluate subcontractors based on their responses to our

subcontractor survey.

13.3 Implementation

SAFETY MANAGEMENT MANUAL

Rev # 14

Chapter 2

Revision date: 08 Apr 2014

Safety and Environmental

Page 12 of 12

Protection Policy

Local TDI-Brooks management is responsible for implementing this policy for each of its

subcontractors. If a sub-contractor violates this policy, then the sub-contractor will take prompt

action to correct such violation to the satisfaction of TDI-Brooks management.

Violation of TDI-Brooks’ policy for sub-contractors, or any applicable policy of a TDI-Brooks

client, or any applicable government law or regulation may be cause for immediate removal and

revocation of access by the offending person to any TDI-Brooks or client property.

14.0

No Lone Deck Work

During normal deck operations, there are several people observing and participating in the

work. However, some tasks must be performed off hours.

When performing deck operations during these times, the worker must have a buddy go with

him and they must have radio communication with the bridge.