Technical specification for the O2 analyzer

advertisement

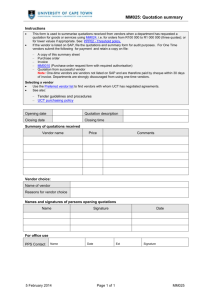

Technical description for procurement of the O2 measurement system. General information about Enefit-140 technology Eesti Energia's oil and gas company (Narva Oil Plant) uses the two Enefit140 units to refine around 1.6 million tons of oil shale per year and produce more than one million barrels of various shale oil fractions. The schematic description of Enefit-140 unit is given on the Fig. 1. Fig. 1. Schematic description of Enefit140 unit. Oil shale crushed to the size <25 mm is fed into the drier (2) where drying and preheating of oil shale are realized in the flow of hot (700– 750 °C) stack gas. Dry preheated to 150-160 °C oil shale is separated from stack gas in the dry oil shale cyclone (3) and fed to the mixer (4), where it is mixed with an 1.9–2.1-fold quantity of hot solid heat carrier (ash of spent oil shale). The mixture is fed into the rotary drum reactor (5) where in the course of 15–20 min over 80% of organic substance of oil shale is converted into liquid and gaseous products. The mixture of spent oil shale and heat carrier from the reactor is separated from the vapor-gas mixture in the dust separator (6) and fed by the screw-conveyor to aero-fountain furnace (7) to produce the ash (solid heat carrier) with temperature of 800 oC. Ash residue from the aero-fountain furnace is transported together with stack gas through the system of cyclones. In the heat carrier cyclones (9) relatively coarse granulometric fraction of ash is separated from the flow of stack gas and directed through the mixer (4) together with oil shale back to the reactor. Excess ash is removed from stack gas in ash cyclones (10). Stack gas is cleaned in the electrostatic precipitator (ESP) (12) before outlet to the open air. Vapor-gas mixture (VGM) produced in the reactor is sent to the condensation section through the dust separator (6), where by means of connected cyclones volatile products are separated from the mixture of spent oil shale and heat carrier. To provide the safety operation of the Enefit140 the content of the oxygen in the stack gases should be in the range of 0-2 vol-%. In this case the ESP is switched to operation. If the oxygen content in the stack gases is over 2 vol-% the ESP is switched to the stand-by mode. The interlock of the ESP operation mode is connected to the measurement of oxygen in the stack gases. Continuous Emission Monitoring System (CEMS). To monitor the composition of stack gases and to see changes in the technological process it was installed Continuous Emission Monitoring System (CEMS). The scheme of the CEMS is attached in the Appendix 1. The system has the gas sample probe (JES 301), heated sampling lines and a container with analytical equipment. Each Enefit140 unit has independent CEMS. CEMS depends on the ESP operation. If the ESP is in operation CEMS is on, when ESP is out of operation CEMS goes automatically to the purging mode. The stack diameter is 1 400 mm. Purpose of the procurement To purchase the system to measure the oxygen content in the stack gases at the startup of Enefit140 units to put into operation the ESP as earlier as possible. The oxygen measurement system should have a low response time. Requirements for the oxygen measurement system The system could be integrated to the existing equipment of CEMS or could be independently installed after ESP. The tenderer should design a system. A type of a measurement system, the location of installation should be approved by Customer. The system should have reliable operation at extremely bad conditions, when the ESP is out operation and the flow contents a high concentration of dust, humidity and aggressive organic chemical compounds, that could cause the optic contamination of analyser. The oxygen measurement system should be connected with the interlocks of ESP and the equipment of existing CEMS. The content of oxygen in stack gases have to be displayed also in the control room. The analyzer measures exact oxygen content from process stream. The data is shown on this requisition. Measured results will be used in a control system for process control. Analyser: O2 analyzer/O2 analysing system Gas: Stack gas Measurement: Measurement principles: Diode laser spectroscopy (TDLS) or another type Measured values: O2 Measuring ranges: O2: 0 ... 5 Vol.-% Normal value: 0.2 Vol.-% Display units: %-vol Repeatability: ± 1 % of the measurement range or better Linearity: ± 1 % of the measurement range or better Accuracy: ± 1 % of the measurement range or better Process temperature: up to +180 C Over pressure in the gas inlet: 0…0.005 bar Ambient temperature: -30…+35 C Device version: Ex-version. Area classification : ExII2GT3 Device version: Cross-duct version or another type of the system (should be approved by Customer) Electrical inputs & outputs: 4...20 mA DC, galvanically isolated. HART OPTION shall also be quoted if available Local display : The analyser system local display, as option Power supply - Voltage: 230 V 50 Hz or 24VDC - Consumption: Bidder to inform on his quotation. Electrical classification: Shall be suitable for installation in hazardous area, classification Zone 1, Group IIC (or IIB+H2), T3. ATEX (CENELEC) certificate is required Housing protection: IP 54 or better Calibration: The analyser calibration shall be carried out manually. All necessary equipment for the calibration of the analyser shall be included to the quotation. Sample gas preparation system Depends on design. If a sample gas preparation system is needed, it should be included to the quotation. Design should be agreed with customer. Utilities available from the purchaser For the analyser and sample handling system following utilities are available: Electricity - For heating : 230/400 V 1-phase 50 Hz and motors : 400 V 3-phase 50 Hz - For instruments: 230 V 50 Hz (preferred) 24 V DC (power supply should be included to the quotation) Dry air (instrumental air) with max pressure of 4 bar Nitrogen in bottle or from the stationary system with pressure of 4 bar. The pressure of nitrogen gas should be specified by Vendor. Other All required utilities shall be specified in the quotation with the quantity needed and any special requirements concerning their quality. If pressure regulators are needed to reduce pressures of the utilities suitable for the analyser, they shall be included in the sample handling system supplied by the vendor. In the case of controversy between these requirements and requirements on Estonia Energy procurement terms and conditioning, shall Estonian Energy conditions prevail. Quantity of measurement systems – 2 pcs. Pricing In the quotation every item shall have its own price. The same principle applies to the documentation, start-up, acceptance tests and training. Documentation See the last sheet of this purchase requisition. Spare parts Priced list of spare parts and maintenance supplies for the start-up and two years operation shall be included in the quotation. Start-up and personnel training The purchaser will take care of all installation activities at site according to installation instructions given by the vendor (equipment, piping, cabling). The vendor's representative shall supervise installations, check and accept the installation before the start-up. This checking means testing of the energised system to see that the supplied equipment is in full operating condition. The vendor's specialist shall carry out the start-up, calibration and training of the purchaser's personnel. Commissioning, start-up and calibration activities should be done with Customer’s engineers. Acceptance test The acceptance test period is 2 weeks without breakdowns caused by the vendor's equipment. During this time the analyser system shall fulfil all specifications as agreed upon the purchase. If the acceptance test run fails due to faults in the vendor's equipment, the acceptance test shall be restarted once they have been fixed. Application warranty The vendor shall give an application warranty for the analyser quoted including the sample handling system for the use specified in this purchase requisition. This means that the purchaser has the right to return the analyser system within 6 months after the start-up, if it does not work as specified in this requisition. In this case the vendor must return the sum paid. The application warranty time begins after accepted acceptance test. The vendor has the right to check and if needed repair the analyser system prior to its return. If the purchaser causes the malfunction (for example the process conditions has been altered or the analyser has been misused) the purchaser and the vendor shall make an agreement on further course of action. Warranty The vendor shall warrant all quoted equipment for a period of 24 months from the date of shipment or 18 months from the date of acceptance test, whichever occurs first. Inspection and testing at factory The purchaser reserves possibility to check the analyser system before the shipment. The vendor has to inform the purchaser four (4) weeks in advance when the analyser system is ready for inspection. Inspection shall include, but not being limited to the following requirements: Visual inspection Leak test for analyser and sample handling system Complete functional test of analyser system hardware and software Eight (8) hours repeatability test run with a gas sample Documentation checking Training The bidder shall include to his quotation training course options covering full scope of system description, documentation description, maintenance, programming, calibration, troubleshooting for Purchaser’s personal. Reference list A reference list of similar deliveries shall be enclosed in the quotation. The bidder shall include to his quotation contact data of some similar reference delivery: Plant, contact person name, phone number and email address. Requirements for documents General requirements The purchase order number, the requisition number and the tag number of equipment shall be marked on all documents and drawings. The equipment shall be marked with the tag number for identification. Documents which will be produced for the delivery in question should be suitable for editing. It’s shall be prepared using MS Office program tools. Drawings shall be prepared using AUTOCAD or MICROSTATION drawing tool. Documents shall be delivered in original data format. Standard documents shall be delivered in PDF format. SI units shall be used. Language of documents All documents in quotation shall be in English and Russian. Documents required for quotation 3 sets (paper and CD’s) of the following documents shall be enclosed with the quotation: General arrangement drawings with main dimensions Price list of spare parts and maintenance supplies for start-up and for one year's operation. ATEX (CENELEC) certification of electrical classification, complete with annexes Documents required after order date for installation To be approved by purchaser Final issue Certified drawings showing Within 6 weeks from 4 paper copies within 4 weeks from overall mounting dimensions and order date as PDF file by purchaser's acceptance. Also one set as installation instructions. email preferred. AUTOCAD 2002 or MICROSTATION dgn files. Complete internal wiring diagram Within 6 weeks from showing required voltage supply order date as PDF file by cable connections, signal output email preferred. etc 4 paper copies within 4 weeks from purchaser's acceptance. Also one set as AUTOCAD 2002 or MICROSTATION dgn files Schematic diagram, lay-out and Within 6 weeks from 4 paper copies within 4 weeks from part list of sample handling system order date as PDF file by purchaser's acceptance. Also one set as email preferred. AUTOCAD 2002 or MICROSTATION dgn files Manufacturing data book (Data sheets of equipment, brochures, certificates) 4 paper copies at the same time with analyser package Instruction manual in English 4 paper copies within 6 weeks from order date Recommendation of calibration mixture 4 paper copies within 6 weeks from order date The vendor shall deliver two CDROM where all documents of current order has been stored: As built drawings as AUTOCAD 2002 or MICROSTATION dgn files, Application Data sheets and instruction manuals as WORD or PDF files. AS-built documentation As-built documentation should include all changes, which was appear during installation and commissioning. The minimum list documentation shall be provided: Technical data and specifications from original vendors for all components for the system Detailed list of full scope instruments, components and spare parts with detailed specification from original vendors. Detailed operating and periodic maintenance instructions with periodic table. Detailed troubleshooting instructions Hook-up’s or instrument’s installation details Electrical, grounding and connection diagrams Cable list Instrument’s location plans Process and system description from project vendor Safety specifications Other type of documents shall be prepared on the Customer’s request Gas composition: O2: 0.2 vol-% H2O: 35-45 vol-% CO2: 13.6 vol-% N2: 56 vol-% CO: 2.56-6 vol-% H2: 0.2-2.81 vol-% CH4: 0.5-1.9 vol-% H2S: 2.9 g/nm3 Dust content: up to 50g/nm3 Gas flow rate: 45 m3/s Appendix 1