View/Open - University of Johannesburg

advertisement

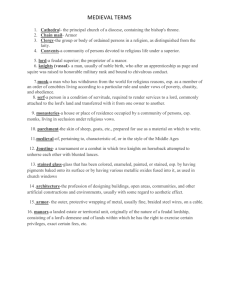

Preparation and Characterization of Polypropylene carbonate Bio-filler (Egg shell powder) Composite Films Ye Feng 1, B.Ashok 2, K.Madhukar 2, Jinming Zhang 1 Jun Zhang 1, K. Obi Reddy 3* and A. Varada Rajulu 2 1 CAS Key Lab of Engineering Plastics, Institute of Chemistry, Chinese Academy of Sciences (CAS), Beijing, 100190, China. 2 3 Department of Physics, Osmania University, Hyderabad – 500 007, India. Department of Chemical Engineering Technology, Doornfontein Campus, University of Johannesburg, Johannesburg, South Africa ABSTRACT In recent years, biodegradable polymer composites have attracted considerable attention, due to the inadequate and depleting petroleum resources and to replace non-biodegradable synthetic polymers posing environment problems. In the present work, biodegradable composites based on polypropylene carbonate (PPC)/egg shell powder (ESP) were prepared by solution casting method using chloroform as the solvent. Polypropylene carbonate was loaded with 1 to 5 wt% of egg shell powder (particle size <40µm). Characterization of the composites was accomplished by Fourier Transform Infrared (FTIR) spectroscopy, thermogravimetric analysis (TGA) and X-ray diffraction (XRD) analysis, and the morphological studies were carried out by optical microscopy (OM) and scanning electronic microcopy (SEM). The tensile properties of the composite films were found to be higher than those of neat PPC matrix and increased with ESP content up to 4 wt.% and then decreased. This work offers an easy path to manufacture eco-friendly PPC/egg shell powder composite films with improved properties, and in some cases, reducing the demand for petroleum based plastics such as polyolefins. Keywords: Polypropylene carbonate; Egg shell powder; Biocomposites; Tensile properties; Thermal degradation; Fractographs. *Corresponding author: K. Obi Reddy, Department of Chemical Engineering Technology, Doornfontein Campus, P.O. Box 17011, University of Johannesburg, Johannesburg-2028, South Africa. E-mail: obireddyk80@gmail.com & obik@uj.ac.za INTRODUCTION Recently, much endeavor has been committed to develop biodegradable and renewable resource-derived polymers because of the worldwide environment concerns and sustainability problems resulting from petroleum-based polymers.[1-2] There is a mounting importance in using renewable resources to develop biodegradable materials-based packaging in order to facilitate integrated waste management approaches.[3-5] Many renewable resource-based biopolymers such as cellulose plastics,[6] starch plastics,[7] polylactides, polyhydroxyalkanoates (bacterial polyesters),[8] and soy-based plastics[9] have been deliberated to alternate conventional non-degradable or incompletely degrading synthetic polymers (e.g. polyolefin’s) in the application scopes of one-off materials.[10] Polypropylene carbonate is a novel biodegradable aliphatic polycarbonate, derived from carbon dioxide (CO2) and propylene oxide and is one such polymer attracting enormous research and industrial attention. The consumption of CO2 as one of the synthetic monomers can largely diminish the dependence on petroleum resources and the release of CO2 contributing to the greenhouse effect.[11, 12] PPC shows reasonable melt processing, excellent tensile toughness, high transparency, and outstanding biodegradability.[13] Generally, this polymer can be used as adhesives, solid electrolytes, polyols, photoresists, barrier materials, flexibilizers and plasticizers.[14] However, certain drawbacks of polypropylene carbonate such as inferior tensile strength, low glass transition temperature and low decomposition temperature limited its commercial applications as a replacement for conventional plastics but makes it attractive as an expiatory material.[15, 16] At the same time as a result, PPC is modified in many ways to develop materials with suitable assets profiles, among others by plasticization, impact modification, and the introduction of fillers or fibers, particularly for industrial applications. [17-19] A preferred solution, blending PPC with low-cost renewable fillers and bio-based toughening agents, is mainly considered in producing environmentally friendly composite materials with improved properties. Egg shell is an important waste material byproduct of poultry industries and domestic dissipate. The egg shell contributes 11% of the total weight of egg. Currently, throughout the world egg production is 65.5 million metric tons by annum with Asia as a key contributor to global egg output growth.[20] By taking 11% of the weight, nearly 7.2 million tons of eggshell waste is created every year. These residue materials if unutilized create a potential pollution problem. Therefore, a resourceful utilization of this waste is of great importance not only for reducing the environmental collision, but also for gaining a higher profit. Eggshell is a natural bio-ceramic composite with a unique chemical composition of high inorganic (~ 95% of calcium carbonate in the form of calcite) and ~5% of organic (type X collagen, sulfated polysaccharides) components.[21] The characteristic structure of eggshell combined with the substantial availability makes eggshells a potential source of bio-fillers that can be efficiently used for polymer composites. Many investigators have studied the effect of fillers on mechanical properties of polymers and the new usage of egg shell powder in the industrial applications. [21-26] The aim of this work was to improve the properties of PPC, reduce its cost by using inexpensive bio-filler and add value to the waste filler. To our best knowledge, no reference has recommended a useful methodology for strength improvement of PPC/egg shell powder composite by the simple solvent film casting method. The present work involved the preparation of biodegradable polymer composite films with bio-filler based on polypropylene and egg shell powder. The composite films were characterized by FTIR spectroscopy, X-Ray diffraction, Thermogravimetric analysis, optical microscopy, electron microscopy and tensile testing techniques. MATERIALS AND METHODS Materials PPC (Mn=50000) was supplied by Tianguan Enterprise Group Company (Henan, China) and used as received. Waste egg shells were washed thoroughly with distilled water several times and dried in the open for several days. The cleaned and dried shells were made into powder using a kitchen grinder-mixer and sieved. The ESP which passed through 40 μm sieve was used as the filler. Analytical grade chloroform (S.D. fine chemicals, India) was used. Preparation of PPC/ESP composite films PPC was dissolved in chloroform to make 10 wt.% solution. Dried ESP was added to this solution at 1 to 5 wt.% and stirred well with a mechanical stirrer. Films of PPC and PPC/ESP composite films were made by the film-casting method. The dried films were separated from the glass plates and stored in a dessicator for prior to further testing. Tensile Testing Rectangular PPC and PPC/ESP composite film strips, 100mm X 10mm with 50 µm thickness, were tested for tensile properties using an Instron 3365 Universal Testing Machine, maintaining a gauge length of 50 mm at a strain rate of 100 mm min-1. For each set, 10 specimens were tested and the average values reported. Microscopic Analysis Optical micrographs of the surface of PPC/ESP composite films were recorded using a Leica DMLP polarized optical microscope. The fractographs of the brittle fractured and gold sputtered composite films were recorded using a JSM 6700 F scanning electron microscope. FTIR Spectral Analysis The FTIR spectra of PPC, ESP and PPC/ESP composite films were recorded in the wave number range of 4000 - 600 cm-1 using an Analect RTF-65A spectrometer in the reflection mode. Thermogravimetric Analysis Primary thermograms of PPC and PPC/ESP composite films were recorded using a thermogravimetric analyzer (PerkinElmer TGA-7). Samples with approximately 10 mg weight were loaded in platinum pans and heated from 30 to 600 oC at a heating rate of 10 oC min-1 under nitrogen dynamic flow (100 mL min-1). RESULTS AND DISCUSSION The composite films produced from PPC with egg shell powder had excellent processability during the solvent-casting method, and they showed good flexibility and no apparent cracks. The tensile parameters (strength, modulus and elongation at break) of the PPC/egg shell powder composite films, determined as a function of filler loading are presented in Table 1. The stress-strain curves of PPC and PPC/ESP composite films are shown in Figure 1. From Table 1, it can be observed that the tensile strength and modulus increased with filler content up to 4 wt.% and decreased thereafter. This behavior could be attributed to better dispersion and filler-matrix interaction between the polymer matrix and finer egg shell powder due to larger surface area associated with the finer filler particles. However, it can be observed that the tensile strength and modulus decreased with filler content more than 5 wt%. This discontinuity could be attributed to increased filler quantity leading to weaker filler-matrix interface and agglomeration of filler particles, which consequently decreased the strength and modulus. Moreover, in all cases, the tensile strength and modulus of the composite films were found to be higher than those of the matrix. At the composition of 4 wt.% filler, tensile strength and modulus of the composite films were found to be 23.2 and 1378 MPa respectively. The increase in tensile strength and modulus of composite films over the matrix was 81 and 67% respectively. It can be seen from Figure 1 and Table that the elongation at break of PPC/egg shell powder composite decreased with increase in filler content. The increase of the filler content in the PPC matrix resulted in the hardening and stiffening of the composite which reduced its ductility, and escorted to lower elongation property. In order to assess the performance of the composite films, their surface adhesion was investigated using an optical and scanning electron microscopy. The surface of the composites films was investigated using an optical microscope. The optical micrographs of PPC/ESP composite films with 1 to 5 wt% ESP are presented in Figure 2. From these micrographs, it is evident that the ESP particles were dispersed uniformly in the composites. This may be due to effective bonding between the matrix and ESP. Further, observation of the morphology of composite films was performed by scanning electron microscopy. Figure 3 shows the micrographs of the brittle fractured composite films with different filler loadings. From Figures 3(a)–3(d), it is evident that ESP particles were distributed uniformly and individually in the PPC/ESP composite films with 1 to 4 wt.% ESP content. However, from Figure 3(e), it can be observed that the ESP particles were agglomerated at some places when the ESP content was 5 wt.%. Further, voids do not appear in the composite films because the solvent completely evaporated in the composite films during the film casting. Also, no gaps appeared between the ESP and PPC due a common carbonate a groups and such a bonding is expected. In order to further investigate the interactions between ESP and PPC in the PPC/ESP composite films, FT-IR spectra were recorded. FTIR spectra of pure PPC, ESP and composite films are shown in Figure 4. The main characteristics of the PPC spectrum are briefly discussed first: In the spectrum of PPC, According to Fei et al.,[27] the wide-ranging absorption band at 3000 cm−1 was due to C-H bond stretching in the propylene units. A strong and spiky absorption band at 1746 cm−1 was attributed to the stretching vibration of carbonyl (C=O) groups. A small absorption band at 1545 cm−1, which might correspond to carboxylate groups present at the ends of the polymer chains. The absorption band in the range of 1470-1380 cm−1 was result of the scissoring and bending of the C-H bonds. The broad and intense absorption band at 1235 cm−1 was assigned to the C-O bond of the carbonate groups. The absorption band at 1167 cm−1 was due to the -CH-O- group. The absorption band at 1065 cm−1 was attributed to the and –O-C=O group. The absorption band at 976 cm−1 was result of the C-C bending of methyl groups. The absorption band at 860 cm–1 was assigned to the –C–C– stretching of the single bond. A strong absorption band at 779 cm–1 was further assigned to the deformation vibration of methylene (-CH2-) groups. FTIR analysis of egg shell powder was performed and is shown in Figures 4. According to Engin et al.,[28] the major absorption bands occurred at 1415, 879, and 700 cm-1, which were attributed to asymmetric stretch, out-of plane bend and in-plane bend vibration modes, respectively, for (CO3)2- molecules. Also broad band of low intensity in the range 3700–3060 cm-1 was attributed to traces of water, together with the very weak, broad band around 1650 cm-1 of hydroxyl (H–O–H) groups bending mode. The spectra of PPC/Egg shell powder composite films are shown in Figure 4 and then the spectra became complicated and it is difficult to reveal the direct interaction according to the changes in band position and band shape. Maybe as the interaction between C=O groups of ESP and CH3 groups of PPC is considered to be the main contribution to the compatibility between ESP and PPC. Also specific intermolecular interactions between PPC and ESP, such as C=O…….O=C dipoledipole interaction, such as a weak hydrogen bonding in between of PPC and ESP to favor the compatibility. Otherwise, no new characteristic absorption bands appeared in the PPC/ESP composite films spectra. From Figure 5, it is evident that PPC because of its predominant amorphous nature showed a broad halo whereas ESP because of the main component of CaCO3 showed crystalline nature. The main and strong peak of ESP appeared at 2θ = 29.3o resulting from (211) plane.[29] However because of overlapping of crystalline peaks of ESP and the amorphous halo of PPC, the peaks of the PPC/ESP composite films could not be identified correctly. In order to observe the filler peaks in the composite films, the diffractograms of ESP and the PPC/ESP composite films were expanded in the 2θ = 29 to 31o and presented in Figure 6. From Figure 6, the crystalline peak corresponding to ESP and ESP in the composite films can be clearly viewed in and around 29.5o. The intensity of the ESP had arbitrary units of 2248 whereas the peaks corresponding to the composite films showed comparatively lower values. The Intensity values of the composite films are also presented in Table 1. From the Table, it is evident that the order of the intensities of the composite films is similar to the order of tensile strength and modulus. Thus the increase in the crystallinity of the composite films due to the inclusion of ESP may also be responsible for the increase in tensile properties. In order to study the effect of ESP content on the thermal stability of PPC/ESP biocomposite films, the thermogravimetric analysis was carried. The primary thermograms of PPC and PPC/ESP composite films are presented in Figure 7. From Figure 7, it is evident that the composite films had higher thermal stability than the matrix. This is as predictable since ESP, due to its major constituent of crystalline calcite, has higher thermal stability than the amorphous PPC. CONCLUSIONS PPC and PPC/ESP composite films with 1 to 5 wt% ESP were prepared by solution casting method using chloroform as the solvent. The tensile strength and modulus of the composite films were found to be higher than for the matrix. At the same time, the %elongation at break of the composite films was lowered by the ESP. The tensile strength and modulus of PPC increased for ESP content up to 4 wt%. The FTIR spectra indicated dipole-dipole interactions between C=O common groups in PPC and ESP. The X-Ray diffractograms indicated increase in the crystallinity of PPC by the incorporation of ESP. The micrographs indicated agglomeration of ESP particles in the composite when the filler content was 5 wt%. The composite films possessed higher thermal stability than the matrix. The completely biodegradable PPC/ESP biocomposites films can be considered for packaging purposes. ACKNOWLEDGEMENTS KOR sincerely acknowledges the Faculty of Engineering and Built Environment, University of Johannesburg, South Africa, for the award of Postdoctoral Research Fellowship. The author AVR thanks the Council of Scientific and Industrial Research of India for the award of an Emeritus Scientist, Scheme [21(0842)11/EMR-II dt:10-05-2011]. REFERENCES 1. Thakur, V. K., A. S. Singha, and I. K. Mehta. 2010. Renewable resource-based green polymer composites: Analysis and characterization. Int. J. Polym. Anal. Charact. 15(3): 137-146. 2. Chen, G. Q., & M. K. Patel. 2011. Plastics derived from biological sources: present and future: a technical and environmental review. Chem. Rev. 112(4): 2082-2099. 3. Davis, G., and J. H. Song. 2006. Biodegradable packaging based on raw materials from crops and their impact on waste management. Indus. Crops Produ. 23(2): 147-161. 4. Thakur, V. K., A. S. Singha, and M. K. Thakur. 2012. Green composite films from natural fibers: Mechanical and chemical aging properties. Int. J. Polym. Anal. Charact. 17(6): 401407. 5. Guerrero, P., T. Garrido, I. Leceta, & K. de la Caba. 2013. Films based on proteins and polysaccharides: Preparation and physical–chemical characterization. Europ. Polym. J. 49(11): 3713-3721. 6. Thakur, V. K., M. K. Thakur, and R. K. Gupta. 2014. Review: raw natural fiber-based polymer composites. Int. J. Polym. Anal. Charact. 19(3): 256-271. 7. Xie, F., E. Pollet, P. J. Halley, and L. Averous. 2013. Starch-based nano-biocomposites. Prog. Polym. Sci. 38(10):1590-1628. 8. Pantazaki, A. A., M. G. Tambaka, V. Langlois, P. Guerin, and D. A. Kyriakidis. 2003. Polyhydroxyalkanoate (PHA) biosynthesis in Thermus thermophilus: purification and biochemical properties of PHA synthase. Molecul. Cellul. Biochem. 254(1-2): 173-183. 9. Swain, S. N., S. M. Biswal, P. K. Nanda, and P. L. Nayak. 2004. Biodegradable soy-based plastics: opportunities and challenges. J. Polym. Environ. 12(1): 35-42. 10. Reddy, M. M., S. Vivekanandhan, M. Misra, S. K. Bhatia, and A. K. Mohanty. 2013. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 38(10): 1653-1689. 11. Chisholm, M. H., and Z. Zhou. 2004. Concerning the mechanism of the ring opening of propylene oxide in the copolymerization of propylene oxide and carbon dioxide to give poly (propylene carbonate). J. Amer. Chem. Soc. 126(35): 11030-11039. 12. Sugimoto, H., and S. Inoue. 2006. Recent progress in the synthesis of polymers based on carbon dioxide. Pure Appl. Chem. 78(10): 1823-1834. 13. Ge, X. C., Y. Xu, Y. Z. Meng, and R. K. Y. Li. 2005. Thermal and mechanical properties of biodegradable composites of poly (propylene carbonate) and starch–poly (methyl acrylate) graft copolymer. Compos. Sci. Technol. 65(14): 2219-2225. 14. Chen S. M., L. Tan, F. R. Qiu, X. L. Jiang, M. Wang, and H. D. Zhang. 2004. The study of poly(styrene-co-p-(hexafluoro-2-hydroxylisopropyl)-α-methyl-styrene)/poly(propylene carbonate) blends by ESR spin probe and Raman. Polymer 45(9): 3045–3053. 15. Yu, T., Y. Zhou, Y. Zhao, K. Liu, E. Chen, D. Wang, and F. Wang. 2008. Hydrogenbonded thermostable liquid crystalline complex formed by biodegradable polymer and amphiphilic molecules. Macromolecules 41(9): 3175-3180. 16. Qin, Y., L. Chen, X. Wang, X. Zhao, and F. Wang. 2011. Enhanced mechanical performance of poly (propylene carbonate) via hydrogen bonding interaction with olauroyl chitosan. Carbohydr. Polym. 84(1): 329-334. 17. Peng, S., Y. An, C. Chen, B. Fei, Y. Zhuang, and L. Dong. 2003. Thermal degradation kinetics of uncapped and end-capped poly (propylene carbonate). Polym. Degrada. Stabil. 80(1): 141-147. 18. Huang, Y., J. Wang, B. Liao, M. Chen, and G. Cong. 1997. Epoxy resins toughened by poly (propylene carbonate). J. Appl. Polym. Sci. 64(12): 2457-2465. 19. Li, Y., and H. Shimizu. 2009. Compatibilization by homopolymer: significant improvements in the modulus and tensile strength of PPC/PMMA blends by the addition of a small amount of PVAc. ACS Appl. Mater. Interfac. 1(8): 1650-1655. 20. Global poultry trends: Asia is key to global Egg Output Growth. It is available in Google Online [http://www.thepoultrysite.com/articles/2735/global-poultry-trends-asia-is-key-toglobal-egg-output-growth] 21. Hassan, S. B., V. S. Aigbodion, and S. N. Patrick. 2012. Development of polyester/egg shell particulate composites. Tribol. Indus. 34(4): 217-225. 22. Ghani S. A., and H. C. Young, 2010. Conductive polymer based on polyaniline-egg shell powder (PANI-ESP) composites. J. Phys. Sci. 21(2): 81-97. 23. Mohammed M. R., and A. N. Hadi. 2012. Effect of egg shell powder on some mechanical and physical properties of natural rubber (NR). Iraqi J. Mech. Mater. Eng. 12(3): 446458. 24. Lin, Z., Z. Zhang, and K. Mai. 2012. Preparation and properties of eggshell/β‐poly Propylene bio‐composites. J. Appl. Polym. Sci. 125(1): 61-66. 25. Sutapun, W., P. Pakdeechote, N. Suppakarn, and Y. Ruksakulpiwat. 2013. Application of calcined eggshell powder as functional filler for high density polyethylene. Polym. Plast. Technol. Engineer. 52(10): 1025-1033. 26. Ashok, B., S. Naresh, K. O. Reddy, K. Madhukar, J. Cai, L. Zhang, and A. V. Rajulu. (2014). Tensile and thermal properties of poly (lactic acid)/egg shell powder composite films. Int. J. Polym. Anal. Charact. 19(3): 245–255. 27. Fei, B., C. Chen, S. Peng, X. Zhao, X. Wang, and L. Dong. 2004. FTIR study of poly (propylene carbonate)/bisphenol A blends. Polym. Inter. 53(12): 2092-2098. 28. Engin, B., H. Demirtaş, and M. Eken. 2006. Temperature effects on egg shells investigated by XRD, IR and ESR techniques. Radia. Phy. Chem. 75(2): 268-277. 29. Krithiga, G., and T. P. Sastry. 2011. Preparation and characterization of a novel bone graft composite containing bone ash and egg shell powder. Bullet. Mater. Sci. 34(1): 177181. CAPTIONS FOR FIGURES Figure 1. Stress-Strain curves of PPC and PPC/ESP composite films with 1 to 5 wt% ESP content. Figure 2. Optical micrographs of PPC/ESP composite films with different ESP contents (a) 1 wt%; (b) 2 wt%; (c) 3 wt%; (d) 4 wt% and (e) 5wt%. Figure 3. Scanning electron micrographs of PPC/ESP composite films with different ESP contents – (a) 1 wt%; (b) 2 wt%; (c) 3 wt%; (d) 4 wt% and (e) 5wt%. Figure 4. FTIR spectra of PPC, ESP and PPC/ESP composite films with 1 to 5 wt.% ESP content Figure 5. X-ray diffractograms of PPC, ESP and PPC/ESP composites films with 1 to 5 wt.% ESP content Figure 6. X -ray Diffractograms of ESP and ESP/PPC composites films in the 2θ=29 to 31o range. Figure 7. Primary thermograms of PPC and PPC/ESP composite films with 1 to 5 wt.% ESP content. Table 1. Tensile properties and X-ray diffraction intensities of PPC/ESP composite films with different ESP content. ESP (%) Tensile Strength (MPa) Tensile Modulus (MPa) Elongation at Break (%) Intensity of (211) peak (Arbitrary Units) 0 12.8±0.5 823±50 821±38 ---- 1 13.1±0.4 974±65 705±26 423 2 14.2±0.5 1008±67 619±21 558 3 17.6±1.2 1206±74 586±17 803 4 23.2±2.5 1378±81 525±19 1006 5 13.8±0.6 983±62 785±15 558 Figure 1. Stress-Strain curves of PPC and PPC/ESP composite films with 1 to 5 wt% ESP content Figure 2. Optical micrographs of PPC/ESP composite films with different ESP contents (a) 1 wt%; (b) 2 wt%; (c) 3 wt%; (d) 4 wt% and (e) 5wt% Figure 3. Scanning electron micrographs of PPC/ESP composite films with different ESP contents – (a) 1 wt%; (b) 2 wt%; (c) 3 wt%; (d) 4 wt% and (e) 5wt% Figure 4. FTIR spectra of PPC, ESP and PPC/ESP composite films with 1 to 5 wt.% ESP content Figure 5. X-ray diffractograms of PPC, ESP and PPC/ESP composites films with 1 to 5 wt.% ESP content Figure 6. X -ray Diffractograms of ESP and ESP/PPC composites films in the 2θ=29 to 31o range Figure 7. Primary thermograms of PPC and PPC/ESP composite films with 1 to 5 wt.% ESP content