1st Quarter Report - University of Florida

advertisement

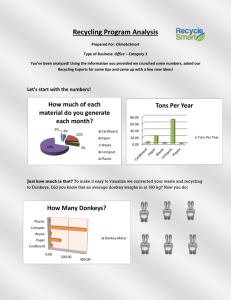

QUARTERLY PROGRESS REPORT August 1st, 2008 – October 31st, 2008 PROJECT TITLE: Impact Analysis of LEED Based Design and Construction on Construction Waste PRINCIPAL INVESTIGATOR(S): James G. Sullivan, PhD. and (Co-PI)Charles J. Kibert, PhD. AFFILIATION: University of Florida COMPLETION DATE: August 2009 PHONE NUMBER: (352) 273-1154 Work accomplished during this reporting period: Background 1. Explain the current construction waste problem. Provide figures exemplifying the problem in the relevant area (Alachua County/Central Florida/Florida). 2. Explain the goal of Waste Management/Diversion. Include definitions of terms that may be unclear: “recycling,” “diversion,” “waste,” etc. 3. Clarify who is responsible for making this goal possible. 4. Bring LEED into the picture. Explain the value of the LEED Rating System. 5. Illustrate the LEED credits that can be obtained through Waste Management/Diversion (MRc2.1 & 2.2). Provide the Intent and Requirements each of these credits require. 6. Discuss UF’s successes using LEED and Waste Management. 7. Provide Definitions. Process 1. Explain the basic process/phases of a construction project. 2. Explain the importance of the preconstruction phase for planning how and when to utilize Waste Diversion strategies. Explain the strategies fully: purchasing materials, subcontractor requirements, architectural considerations (designing for deconstruction), etc. 3. Break down the materials present on a jobsite a. How to purchase effectively b. How to use most efficiently (value, handling, constructing, etc.) c. Where/How to recycle d. How to document the diverted waste 4. Other steps/ideas for Waste Management/Diversion before, during, and post construction. Information Dissemination Activities: To be scheduled Spring 2009. TAG meetings: Informal meetings ongoing. Formal meetings scheduled for Spring 2009. Summation of work accomplished during this reporting period: BACKGROUND Construction and Demolition Debris (C&D) is defined in Florida Statute 403.703 as “discarded materials generally considered to be not water-soluble and nonhazardous in nature, including, but not limited to, steel, glass, brick, concrete, asphalt roofing material, pipe, gypsum wallboard, and lumber, from the construction or destruction of a structure as part of a construction or demolition project or from the renovation of a structure, and includes rocks, soils, tree remains, trees, and other vegetative matter that normally results from land clearing or land development operations for a construction project, including such debris from construction of structures at a site remote from the construction or demolition project site.” Currently, the United States Environmental Protection Agency (EPA) estimates more than 136 million tons of debris is generated annually by building-related construction and demolition. This value indicates that over 40% of the Construction and Demolition and municipal solid wastestream is a direct result of the construction industry (U.S. EPA). Obvious demand for a change in waste procedures in the construction industry. Brought about Waste Diversion and Waste Management Plans. There are a number of methods utilized to divert waste. All of these methods aim to limit the amount of waste transported from a construction or demolition project to a landfill. Waste management practices are also seen in the USGBC’s LEED rating systems. The USGBC, or United States Green Building Council, has been highly effective in changing the environmental ethics of construction. The USGBC aims to improve conventional construction methods by implementing a series of LEED rating systems. LEED (especially MRc2.1 and 2.2) Utilizing LEED and Waste Management practices has proven to be successful for the University of Florida, located in Alachua County, Florida. Before the USGBC and LEED movement, there was little influencing contractor’s requirements to recycle. Until 1997, Florida had minimal requirements for C&D recycling. A 1988 legislation established C&D recycling goals for each county, but it wasn’t until 1997 that this C&D disposal legislation was reinforced. The stricter disposal requirements resulted in increased desire to recycle C&D debris. For additional legislative and regulatory background read C&D Debris Recycling Study: Final Report. In Alachua County, this stronger legislature may have been the cause for the lower percentage of C&D waste in 1998. The Florida Department of Environmental Protection recognized C&D waste as 17% in 1998, while the percentage of C&D waste in 1996, 1997, 1999, and 2000 were between 23% and 29%. These figures remained steady both before and after the drop in 1998. It wasn’t until 2004 that a decrease was seen again. In 2004, The Florida Department of Environmental Protection credited C&D Waste for 14% of the total waste generated in Alachua County. It was also in 2004 that the first LEED certified building was built on the University of Florida campus. This figure is down drastically from 29% in 2000. This may be a result of the University of Florida’s efforts to build highly efficient buildings. With use of the USGBC’s LEED rating systems, the University of Florida has constructed fourteen certified buildings to date. There are currently fifteen other projects in the early phases of construction which will all be LEED certified. All new construction at the University of Florida is required by the college to achieve a LEED certification. Since the university currently requires high standards for building efficiency, reaching certification does not require much additional cost or effort. The university has a number of methods in place to ensure the success of all construction projects. One of the methods utilized is the University of Florida Solid Waste Reduction Program. This program offers recycling of paper products, cardboard, plastics, batteries, scrap metal, yard debris, glass, lumber, and a variety of other materials. This program, in conjunction with the contractors’ Waste Management Plans has allowed approximately 76% of the waste produced on a project attaining a MRc2.1 or 2.2 credit to be diverted from landfills. (See spreadsheet) The success of UF’s Recycling and Waste Management Plans may be responsible for the drastic decrease in C&D waste in Alachua County. The following document provides guidelines for creating a successful Waste Management Plan specific for every construction project. Following these guidelines, the Waste Management Plan implemented should be capable of getting all parties motivated, purchasing appropriate materials, limiting C&D waste, and ultimately attaining LEED MRc2.1 and 2.2. MATERIAL SELECTION CRITERIA/PROCESS (Sustainable Building Technical Manual) Public Technology Inc. and the USGBC have created a resource efficiency document presented in the Sustainable Building Technical Manual. Included in the “materials” chapter is a checklist of suggested practices for material selection. The Material Selection Criteria discusses resource quantity, reused materials, recycled content, rapidly renewable resources, local content and reduced transportation, regionally appropriate materials, life cycle cost and maintenance requirements, resource recovery and recycling. Some of these conditions apply to waste diversion and will be discussed further in depth. Resource Quantity o Objective: Since the overall aim of waste management is to limit the amount of waste produced, material purchasing would be the root of the goal. By purchasing less of a material, the resource will be used in smaller amounts and more efficiently. Ultimately, there will be less waste. o Strategy: In order to achieve this task, a capable material estimation technique should be utilized. This method should be evaluated at the conclusion of each project to ensure the method is up-to-date and capable of outputting acceptable quantities. Purchasing materials in a series, as opposed to in bulk, may also cut down on resource quantity. During the last purchase only what is needed will be ordered. This will also limit the amount of materials onsite, and the materials exposure to weather and other damaging factors. Reused Materials o Objective: There are a number of products and materials that can be easily reused. Some of these products include doors, glass, and metals. Though deconstructing to be sure products are reusable might cause additional effort, the cost savings of using a salvaged material can be considerable. The goal is to keep these useful materials and products away from a landfill. o Strategy: Contact a salvage company. The salvage company can assist by coming on-site and removing valuables or by providing the project with valuable products for reuse. Either way, the materials will avoid becoming waste. Utilizing enough of these materials can provide up to two LEED credits: Materials and Resources credit 3.1 and 3.2. Recycled Content o Objective: Utilizing materials with recycled content limits negative effects on the natural environment in two ways: fewer resources must be extracted from the environment and the recycled material used for replacing the resources is diverted from a landfill (waste diversion). o Strategy: Purchase materials with high percentage of recycled content. Recycle all waste capable of being used in creating a recyclable product. Utilizing enough of these materials can provide up to two LEED credits: Materials and Resources credit 4.1 and 4.2. Life Cycle Cost o Objective: Selecting a product or material based on the Life Cycle Cost is advantageous for the future of the building. Some materials will not outlast the life of the building, for this reason they will have to be replaced and may end up in a landfill. o Strategy: Select products based on the Life Cycle Cost to ensure the products will not need to be replaced in the near future. By expanding the life of the product, it will not need to be replaced as often. Replacing a product less will ultimately result in less products failing and ending up in a landfill. Therefore selecting materials with a longer life span will ultimately divert waste. Not necessarily related to waste diversion, the following are other suggestions to consider when selecting and purchasing materials. Rapidly Renewable Resources o Objective: The USGBC defines a rapidly renewable resource as a material or product “made from plants that are typically harvested within a ten-year cycle or shorter.” The goal of utilizing these resources is to limit the use of materials that are not as easily renewable. o Strategy: Purchase and use rapidly renewable resources to replace other resources not capable of quick renewability. These materials may include bamboo, cotton insulation, or cork. If enough rapidly renewable resources are used, it can provide an addition LEED credit: Materials and Resources credit 6. Life Cycle Cost and Maintenance Indoor Air Quality Issues o Objective: The use of certain products or materials can cause poor indoor air quality, including volatile organic compounds (VOCs), fiber shed, and dust from finishing. o Strategy: The USGBC recommends reviewing the emission levels from the building products selected. A review should be performed for installation, duration of building life, and removal. Proper selection of these materials can result in four LEED credits for Indoor Environmental Quality: EQ 4.1 - 4.4. PROCESS DURING PRECONSTRUCTION 1. Develop main goals of the Waste Management Plan. GOAL 1: This project will generate the least amount of waste possible. GOAL 2: The majority of the waste created on this project will be recycled. GOAL 3: Work to guarantee full involvement in the plan. GOAL 4: Be knowledgeable of Waste Management Plan’s progress and efficiency. 2. Explore required materials. Run through project plans and specifications and determine what materials will be utilized on the project and may produce waste. Determine the amount of materials that will be sufficient yet produce the least waste. When purchasing materials consider the material selection criteria previously discussed: resource quantity, reused materials, recycled content, etc. Examine specifications for areas in which recycled materials can be used as an alternate to the materials selected by the architect or owner. Refer to Construction Material Purchasing and Planning Guide (Appendix 1) to ensure materials selected are as beneficial to environment as possible. Utilize the Waste Diversion Assessment Plan (Appendix 2) to estimate anticipated waste for materials on the project. Also using this document, determine which facilities in the area will divert the estimated waste and what diversion method will be used to ensure maximum recyclability (see Construction Material Purchasing and Planning Guide for additional help). Set the Project Diversion Goal at the bottom of the Diversion Assessment Plan. “This project will divert XX% (by weight) of the total waste generated.” 3. Select a Waste Management Coordinator Qualify and select a Waste Management Coordinator to ensure worker involvement and proper organization of the diversion process. Individual should posses a LEED AP certification and be knowledgeable in waste diversion practices. The Coordinator should contact the chosen recycling and waste facilities to inquire which materials are acceptable, acquire the necessary dumpsters and/or recycling receptacles, and organize collections and/or drop offs for the duration of the project. Be sure these facilities can provide proof of trash/recyclables weight and receipts tracking the transfers. The Coordinator should be aware and confident in the Project Diversion Goal. Coordinator should ensure each subcontractor is familiar with the LEED process, especially Material and Resource credits 2.1 and 2.2. Coordinator should present the Waste Management Plan, goals, and Project Diversion Goal to each subcontractor and key players on the project. These individuals must agree to the plan and sign-off on the goal sheet (be sure the goals and policies also exist in the Subcontractor’s contract with the General Contractor). Coordinator should assist management in organizing the project site. 4. Set up project for the success of the Waste Management Plan. a. Site: Determine how many bins and of what size will be required for this specific project. Depending on the type of building and project requirements, bins could be provided for all or some of the following: asphalt, cardboard, concrete/CMU/brick, glass, gypsum board, paper, plastic, metal, and wood. When selecting bins consider larger receptacles with multiple compartments. Also consider smaller bins to place in more locations for materials that will be recycled more frequently. Smaller bins with wheels are advantageous for end of the day collection into the larger bin. Set up a site plan that will designate the main location for waste and recycling containers, as well as locations for smaller bins. Smaller bins should be located by workspaces needing these bins. Be sure the dumpsters and recycling receptacles are easily accessible for pick-up. Be sure each dumpster or receptacle is marked to clearly identify which materials are acceptable: “Metal Only,” “Concrete/Rubble,” “Clean Wood,” etc. Mark areas for material storage to protect from weathering or other damage. Set up a mutual cutting area. This ensures reuse of materials before cutting of new ones. b. Office: Designate an area for the office or jobsite trailer to establish receptacles. Provide separate bins for recyclable materials: aluminum, plastic, paper, ink cartridges, etc. Assign a specific area for filing the Waste Management Plan, Goals, and all corresponding documents. DURING CONSTRUCTION 1. Materials Follow tips provided on Construction Material Purchasing and Planning Guide to ensure efficient use, proper handling, disposal methods and reuse strategies of specific materials. Carefully handle and store materials to ensure no materials are broken and materials can be reused where possible. Return any excess materials that are not used to the vendor. If they cannot be returned offer to the owner, workers, or donate the materials to a charity before considering it waste. Refer to Construction Material Purchasing and Planning Guide for material handling, disposal methods and reuse strategies. Coordinate material deliveries with schedule to minimize the amount of time materials are onsite and exposed to weathering or damage. Maintain construction equipment properly to guarantee maximum life. 2. Managing the Waste Diversion Process Management should monitor Waste Management Coordinator to make certain the following responsibilities are completed appropriately. The Coordinator must remind subcontractors of the goals and responsibilities for the Waste Management Plan. This should be done throughout the entire project duration. The Coordinator should also post the Waste Management Goals in a prominent location for all to view. The Coordinator should provide tours to all workers, ensuring their knowledge of proper waste sorting and placement. Coordinator should provide each subcontractor with a site plan clearly marking which areas are designated for storage, cutting, and recycling. Trash and recycle bins should be clearly marked with acceptable materials. The Coordinator should be present at safety or toolbox meetings to remind workers of their commitment to waste diversion. This is also in effort to keep workers motivated. Coordinator must monitor each subcontractor and worker’s actions to ensure the proper placement of recyclable materials. Subcontractors should aim to reuse their own materials on the project. If not possible, subcontractors can save their materials for a future project. Subcontractors should aim to keep their waste separate from other’s waste to ensure easy separation for recycling. If it is found that workers are not taking initiative to separate the materials, require them to pick through the trash they produced and hand separate the materials. This will limit contamination by workers in the future. Suppliers should be urged to use sturdy pallets and pick-up them up for reuse. Coordinator should periodically check receptacles and trash to make sure materials are not in the wrong bin. When a dumpster or recycling receptacle is full it is the Waste Diversion Coordinator’s duty to arrange a pick-up. The Coordinator must oversee proper procedure for all documentation of waste and diverted materials. 3. Documentation Upon dumpster or recycling bin removal, fill out a Jobsite C&D Debris Log (Appendix 3). Be sure this document is filled out fully with material descriptions, quantity of materials diverted and taken to the landfill, totals of these materials, and finally signed by the appropriate parties and filed correctly. Get verification from waste facilities of diverted and non-diverted waste. Any verification from the collection facility should be attached to the Jobsite C&D Debris Log. File these documents correctly. Utilize Jobsite C&D Debris Logs to create a monthly progress report to present to the owner, subs, and workers. Keep track of diversion costs and savings. Submit to appropriate department. Document plan with photographs throughout project duration. If possible keep a Photo Log. POST CONSTRUCTION 1. Documentation Examine and total all Jobsite C&D Debris Logs. Fill out final Jobsite C&D Debris Project Totals (Appendix 4). Determine the percentage of Overall Waste Diverted in pounds. Compile all necessary documentation for LEED MRc2.1 and 2.2 to turn into USGBC. Compare percentage of Overall Waste Diverted to the Project Diversion Goal. Determine how efficient the project has managed the waste and what can be done to improve the efficiency. Determine which materials had the largest amount of excess material and if the current material estimating strategy should be reassessed. For future use, document which facilities were most accommodating at diverting waste. 2. Awards In order to ensure future participation, provide Subcontractor’s who excelled in waste diversion with a symbol of appreciation.