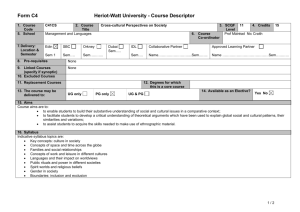

Heriot-Watt University

advertisement

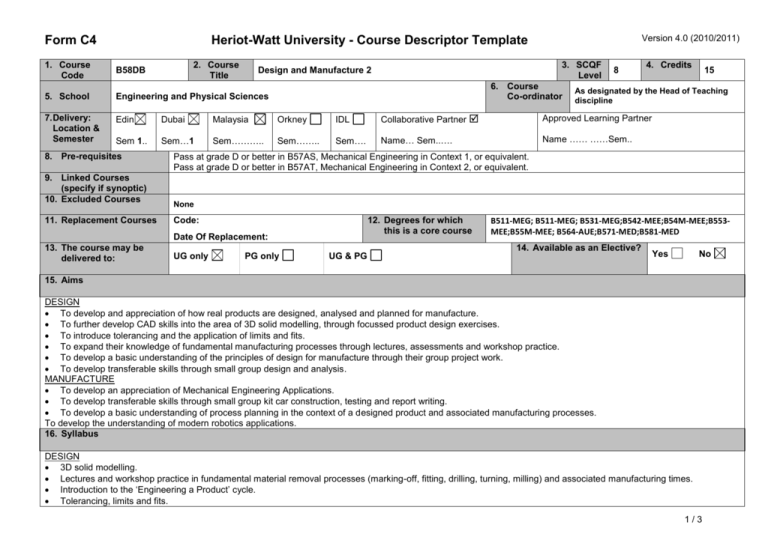

Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template 1. Course Code B58DB 5. School Engineering and Physical Sciences 7. Delivery: Location & Semester Edin Dubai Malaysia Orkney IDL Collaborative Partner Approved Learning Partner Sem 1.. Sem…1 Sem……….. Sem…….. Sem…. Name… Sem..…. Name …… ……Sem.. 8. Pre-requisites 9. Linked Courses (specify if synoptic) 10. Excluded Courses 11. Replacement Courses 2. Course Title 6. Course Co-ordinator 8 4. Credits 15 As designated by the Head of Teaching discipline Pass at grade D or better in B57AS, Mechanical Engineering in Context 1, or equivalent. Pass at grade D or better in B57AT, Mechanical Engineering in Context 2, or equivalent. None Code: 12. Degrees for which this is a core course Date Of Replacement: 13. The course may be delivered to: 3. SCQF Level Design and Manufacture 2 UG only PG only UG & PG B511-MEG; B511-MEG; B531-MEG;B542-MEE;B54M-MEE;B553MEE;B55M-MEE; B564-AUE;B571-MED;B581-MED 14. Available as an Elective? Yes No 15. Aims DESIGN To develop and appreciation of how real products are designed, analysed and planned for manufacture. To further develop CAD skills into the area of 3D solid modelling, through focussed product design exercises. To introduce tolerancing and the application of limits and fits. To expand their knowledge of fundamental manufacturing processes through lectures, assessments and workshop practice. To develop a basic understanding of the principles of design for manufacture through their group project work. To develop transferable skills through small group design and analysis. MANUFACTURE To develop an appreciation of Mechanical Engineering Applications. To develop transferable skills through small group kit car construction, testing and report writing. To develop a basic understanding of process planning in the context of a designed product and associated manufacturing processes. To develop the understanding of modern robotics applications. 16. Syllabus DESIGN 3D solid modelling. Lectures and workshop practice in fundamental material removal processes (marking-off, fitting, drilling, turning, milling) and associated manufacturing times. Introduction to the ‘Engineering a Product’ cycle. Tolerancing, limits and fits. 1/3 Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Engineering applications individual and group project design work (2 projects, one fabricated assembly and another small mechanical assembly). MANUFACTURE Kit car construction, analysis and testing. Process Planning and the ‘Engineering a Product’ cycle. GENERAL IMechE EA Logbook preparation, organisation and submission. 17. Learning Outcomes (HWU Core Skills: Employability and Professional Career Readiness) Subject Mastery Personal Abilities Understanding, Knowledge and Cognitive Scholarship, Enquiry and Research (Research-Informed Learning) Skills Demonstrate knowledge and understanding of product design and manufacture through design projects. To appreciate tolerancing in the context of designed components and assemblies and apply these accordingly. Develop basic understanding of manufacturing fundamental manufacturing processes and the limitations they impose on designed parts and assemblies in terms of features manufactured, cost and time. Develop advanced CAD 3D modelling skills to a level to be applied in project work. To carry out fundamental analysis as part of the design process. To appreciate the importance of keeping a professional record of engineering experience. To develop further knowledge and understanding of robotics through structured laboratories. Industrial, Commercial & Professional Practice Autonomy, Accountability & Working with Others Communication, Numeracy & ICT Development and application of the cognitive skills associated with the creative product design process and to be prepared to make important, compromise decisions. Apply analytical skills to manufacturing processes. Ability to apply acquired skills to problem solving processes, e.g. DFM, DFA, process awareness. Development of generic sketching and CAD skills applicable to any creative engineering design task. Develop awareness of the process of engineering products through project-based and workshop-based learning. General awareness of engineering workshop practice. Develop practical engineering skills and method planning skills through process planning, kit car construction, analysis and testing. Develop transferable skills through work in groups, analysis and presentation of results in Lab reports. Develop design skills through design, building and testing of an engineered component. Develop understanding of modern robotics and its practical applications. Awareness of CEng requirements regarding academic and industrial experience through logbook activities. 18. Assessment Methods 19. Re-assessment Methods Method Duration of Exam Weighting (%) Synoptic courses? Method (if applicable) Continuous assessment Design Manufacture Logbook 20. Date and Version Duration of Exam Diet(s) (if applicable) 100 (45) (45) (10) Remedial Work Examination 2 hours (OPEN BOOK) 3 2/3 Form C4 Date of Proposal Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Date of Approval by School Committee Date of Implementation Reworked Nov 14 (SH) Version Number 3/3 V1