Electrodeposition - People - Rochester Institute of Technology

advertisement

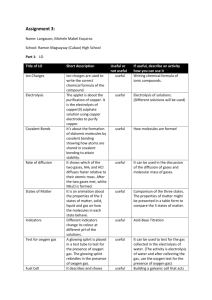

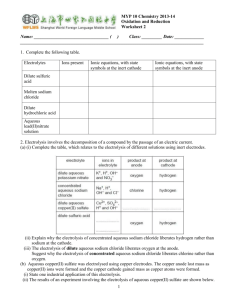

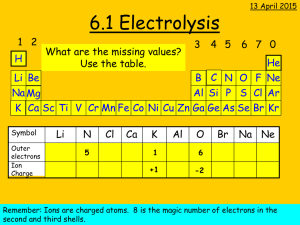

ELECTROGRAVIMETRIC ANALYSIS OF COPPER INTRODUCTION Most copper-containing compounds can be electrolyzed in acidic solutions, with quantitative deposition of Copper (Cu) at the cathode. Sections 17-1 and 17-2 of Quantitative Chemical Analysis by Daniel C. Harris discuss this technique. When a Platinum (Pt) anode and cathode are placed in solution of Cu2+, and an electric current is passed through, a deposit of copper metal will occur on the cathode and Oxygen (O2) will be liberated from the anode. Deposition occurs with the following reaction: ↔ Cathode: 2Cu2+ + 2e- Anode: H2O ↔ ½ O2(g) + 2H+ + 2e-----------------------------------------------------------H2O + Cu2+ ↔ Cu(s) + ½ O2(g) + 2H+ Net reaction: (17-1)1 Cu(s) In electrogravimetric analysis, the electrode is carefully weighed before and after deposition and the increase in mass tells how much analyte was deposited. Various percentages of copper ore are provided as the unknown. There are three ways to observe completeness of the deposition. The first is to observe the disappearance of the color of the solution. This is seen because the colored species is the Cu2+, which is a light blue in color. The second observation is to expose most of the surface of the cathode to the solution during electrolysis by then adding water to the solution and seeing if more copper is deposited on the previously uncovered Pt. This is the method used in this lab. Alternately, remove a drop of solution and perform a qualitative test for copper. The samples must be free of chloride and nitrous acid.2 Copper oxide unknown (soluble in acid) are available from Thorn Smith.3 The apparatus shown in Figure 17-5 of the textbook uses any 6–12 V direct-current power supply. Figure 1. Experimental Set up for Deposition of Copper1 SCHA 262 (4/11/2005) Electrodeposition of Copper Page 1 of 4 Figure 1 shows the experimental setup for this experiment, showing the positioning of the electrodes as well as the current path setup. General safety equipment is needed for this experiment. Remember to always wear gloves, goggles, and a lab apron or coat. All procedures for this experiment should be performed in a fume hood. MATERIALS NEEDED 250mL beaker 100mL graduated cylinder Pt gauze cathode Pt spiral or gauze anode Magnetic stirring bar 2 ring stands Hot/stirring plate Direct-current power supply Analytical Balance Fume hood Desiccator CHEMICALS NEEDED 8M HNO3 Copper unknown sample Distilled water Ethanol SAMPLE PREPARATION 1. Obtain unknown sample and record unknown number in lab notebook. 2. Weigh one gram of unknown sample on an analytical balance and transfer completely to a 250mL beaker. 3. Add about 30mL of 8M HNO3 and heat on a hot plate to dissolve the sample into solution. Warning: Great care should be taken in the handling of nitric acid. Nitric acid can cause potentially severe chemical burns that result in the skin turning yellow and flaking off. 4. When the solid has dissolved, add distilled water for a final volume of 150mL. CLEAN THE ELECTRODE 1. Handle the Pt gauze with a kimwipe. SCHA 262 (4/11/2005) Electrodeposition of Copper Page 2 of 4 Caution: When handling the Pt gauze cathode, only touch the thick stem and not the gauze. This could result in contamination or transfer of fingerprints or damaging the cathode. 2. 3. 4. 5. 6. Immerse the electrode in hot 8M HNO3 to remove previous deposits. Rinse with distilled water. Rinse with Ethanol. Dry in 105°C oven for 5 min, cool in desiccator for 5min. Weigh accurately using analytical balance and record weight. Note: If the electrode contains grease or any material that does not come off in nitric acid, it can be heated to red heat over a burner after the treatment above4. SET UP THE ELECTROLYSIS SYSTEM 1. Set up the electrolysis system as seen in figure 2. Figure 2. Diagram of Electrolysis system5 2. Position the cathode so that the top 5mm are above the liquid level after magnetic stirring has begun. 3. Adjust current to 2 A, which should require 3-4 V. Warning: The required current needed is enough to kill an adult human. Do not touch the connector pins while the direct-power supply is in operation, at the risk of severe electric shock. 4. Add some distilled water when the blue color of Cu(II) has almost disappeared so that new Pt surface is exposed. SCHA 262 (4/11/2005) Electrodeposition of Copper Page 3 of 4 Note: If no further deposition of Cu occurs on fresh surface in 15 min, the electrolysis is complete. If deposition is observed, continue electrolysis and test the reaction for completeness again. DETERMINE AMOUNT OF COPPER 1. Without turning off the power, lower the beaker while washing the electrode with distilled water. 2. Turn the current off. Caution: If current is disconnected before removing the cathode from the liquid and rinsing off the acid, some Cu could redissolve and electrolysis will have to be repeated. 3. Wash cathode gently with water and alcohol. 4. Dry at 105°C for 3 min, cool in a desiccator for 5 min, and weigh. 5. Record final mass. CONCLUSION Determine the amount of copper present in your ore sample. It will contain between 5 and 20 percent. This experiment will be preformed twice to increase the accuracy of the readings and obtain a smaller margin of error. 1 Harris, Daniel C. Quantitative Chemical Analysis. 6th ed. W.H. Freeman and Co., NY. 2003. pp.373-379 J. F. Owen, C. S. Patterson, and G. S. Rice, Anal. Chem. 1983, 55, 990, describes simple procedures for the removal of chloride from Cu, Ni, and Co samples prior to electrogravimetric analysis. 3 Thorn Smith Inc., 7755 Narrow Gauge Road, Beulah, MI 49617. Phone: 231-882-4672; E-mail: www.thornsmithlabs.com. 4 Some metals, such as Zn, Ga, and Bi, form alloys with Pt and should not be deposited directly on the Pt surface. The electrode should be coated first with Cu, dried, and then used. Alternatively, Ag can be used in place of Pt for depositing these metals. Platinum anodes are attacked by Cl 2 formed by electrolysis of Clsolutions. To prevent chlorine attack, 1–3 g of a hydrazinium salt (per 100mL of solution) can be used as an + anodic depolarizer, because hydrazine is more readily oxidized than Cl -: N2H4 2 + 4H + 4e . 5 Kohn, Julia. Hand drawing, 2 SCHA 262 (4/11/2005) Electrodeposition of Copper Page 4 of 4