Instructions Sent With Kits

advertisement

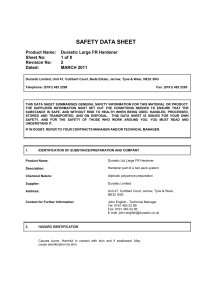

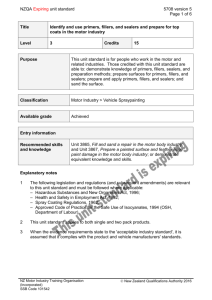

Instructions Mixing ratio….. Budget mix 2% Hardener – You work this out by dividing the paint quantity by 100, then multiplying that figure by 2… For example 250ml /100 = 2.5 x 2 = 5… So for 250ml of solution you add 5ml of hardener. Premium mix – 5:1 Ratio…. This means, 5 parts solution, 1 part hardener – These kits are already mixed unlike the budget, so you just mix the two parts together – Simple! The Obvious… I shouldn’t need to state the obvious, but because there is always less hardener than solution, with both kit ranges, there is no need to worry thinking one of the containers has somehow leaked. I have had several eBay members asking why one container is less than the other, who struggle to grasp a ratio. Also all the kits are hand mixed, so from time to time, there may be a bit of paint on the cans, or a sticky residue here and there… It’s nothing to worry about! I do my best to make sure all paint containers / cans are clean, but some do slip through. Simple Instructions… The broken down instructions are here, for more in depth instructions please see the website (data sheets & pictures all available online – www.rustypaint.com) Prepare the surface you are painting, key the surface with some sand paper (320 grit or higher) and fully degrease. Next mix the premium paint & premium clear liquid together (see mixing instructions above if you are using a budget kit). If the premium clear liquid has turned to a gel (due to temperature), you will need to agitate it by violently shaking the bottle, and then can either warm the bottle up to turn the gel into liquid, or directly add the paint to the clear liquid (hardener), and shake the bottle thoroughly. You need to make sure the kit is thoroughly mixed, so take your time on this step!! Next you want to apply your paint to the surface, this can be done with a paintbrush, roller or normal spray gun. Leave to dry, and once fully cured, sand/scotchbrite the areas you want the rusting to come through. Make sure you sand (using 320 grit or lower) until you have a nice solid silver sheen of specs, (not just a few here and there) remember, the more silver specs the quicker it will start rusting!! Once you are happy with your sanding, wash the surface thoroughly with some warm soapy water to remove any sanding residue, and leave to dry. If you want to kick start the rusting process, you can mix white vinegar & bleach together on a 1:1 ratio, spraying on the surface and adding salt. DO NOT inhale the vinegar & bleach mix - Wear goggles, gloves and a mask! If you have any issues with the product not rusting, it will be either the item is not sanded enough, or you have not cleaned it thoroughly after sanding, and there is some sanding residue causing a barrier. This product is for professional use only. The information given on the site and in this leaflet is for guidance only. Any person using this product without first making further enquiries as to the stability of the product for the intended purpose does so at his own risk. We can accept no liability for the performance of the product for any loss or damage (other than death or personal injury resulting from our negligence) arising out of such use. The information contained on the site and this sheet is liable to modification from time to time in the light of our experience and our policy of continuous development. Drying times quoted are average times at 20c. Film thickness, humidity and shop temperature can all effect drying times. Hardeners do have the ability to set, so should be used expeditiously.