Cell Sorter Lone Working Risk Assessment

advertisement

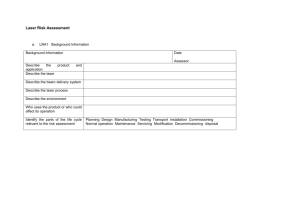

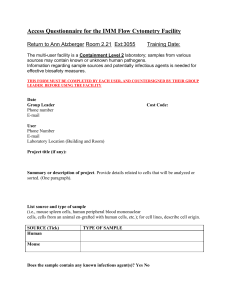

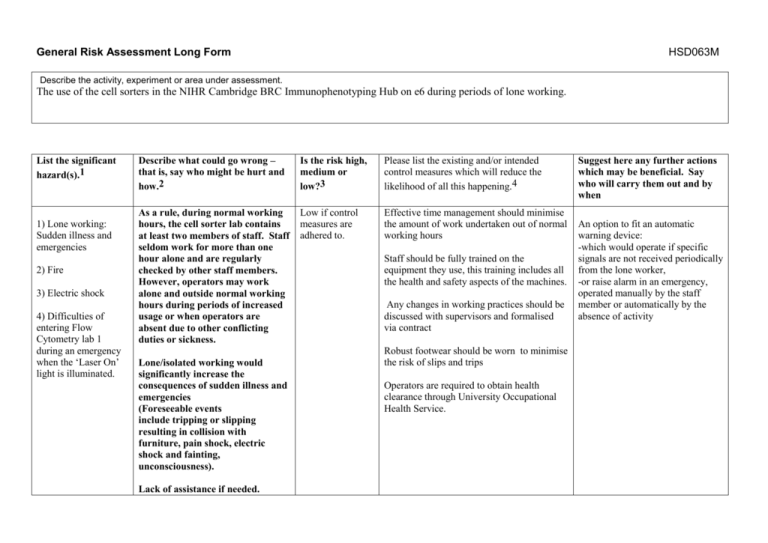

General Risk Assessment Long Form HSD063M Describe the activity, experiment or area under assessment. The use of the cell sorters in the NIHR Cambridge BRC Immunophenotyping Hub on e6 during periods of lone working. List the significant hazard(s).1 i) ii) iii) iv) v) vi) vii) viii) ix) 1) Lone working: Sudden illness and emergencies 2) Fire 3) Electric shock 4) Difficulties of entering Flow Cytometry lab 1 during an emergency when the ‘Laser On’ light is illuminated. Describe what could go wrong – that is, say who might be hurt and how.2 Is the risk high, medium or low?3 Please list the existing and/or intended control measures which will reduce the likelihood of all this happening.4 As a rule, during normal working hours, the cell sorter lab contains at least two members of staff. Staff seldom work for more than one hour alone and are regularly checked by other staff members. However, operators may work alone and outside normal working hours during periods of increased usage or when operators are absent due to other conflicting duties or sickness. Low if control measures are adhered to. Effective time management should minimise the amount of work undertaken out of normal working hours Lone/isolated working would significantly increase the consequences of sudden illness and emergencies (Foreseeable events include tripping or slipping resulting in collision with furniture, pain shock, electric shock and fainting, unconsciousness). Lack of assistance if needed. Staff should be fully trained on the equipment they use, this training includes all the health and safety aspects of the machines. Any changes in working practices should be discussed with supervisors and formalised via contract Robust footwear should be worn to minimise the risk of slips and trips Operators are required to obtain health clearance through University Occupational Health Service. Suggest here any further actions which may be beneficial. Say who will carry them out and by when An option to fit an automatic warning device: -which would operate if specific signals are not received periodically from the lone worker, -or raise alarm in an emergency, operated manually by the staff member or automatically by the absence of activity Inadequate provision of first aid (failing to provide medical help as the person has not been missed/noticed due to isolated working) Flow cytometry Personnel x) Fire risk, lone working may increase the chance of a fire being unnoticed and overcoming the operator before an alarm could be raised. Low if control measures are adhered to. There is a smoke detector connected to the building’s fire alarm that would alert Reception/Security of the presence of fire. All staff must receive fire safety training Flow cytometry Personnel xi) Electric shock: caused through faulty equipment or whilst handling high voltage plates when trying to rescue a cell sample during breakdown of cell sorting machines. Low if control measures are adhered to. As written down in the standard operating procedures the plates should only be handled when the voltage is off. Flow Cytometry Personnel xii) Difficulties of entry into Flow Cytometry lab 1 for personnel responding to emergency. During an emergency access to the Flow Cytometry lab 1 is hindered by local rules, where no personnel are allowed access if the ‘laser light’ warning light is illuminated. Security Staff, Laboratory Managers, Fire Brigade Medium unless new control measures are introduced. A contingency plan should be prepared in case the lone worker falls ill, there is an accident, or there is an emergency such as a fire or chemical spillage. This plan should include provision for entry into the Flow Cytometry lab 1 when the ‘laser on’ light is illuminated, indicating the laser is in use. This should incorporate an ‘emergency power off’ switch to be located outside the door. The switch should be covered and locked during normal working hours and keys held in reception and with laboratory manager for immediate access to operators. Outside normal working hrs the switch should not be locked Simon McCallum will discuss this plan and lone worker policy with Alan Brownlee in first instance and obtain information/quotation how much such a switch would cost and whether department or group would be charged In the event of an alarm being raised or failure of personnel to respond, If ‘Laser On’ sign is illuminated, Security staff/Lab Management/Fire brigade should 1) Call x30149 2) If no response; knock on the door 3) If no response; turn off the power using the emergency power off switch and gain access. If the ‘Laser on’ light is out enter without delay. Important! It is essential to check regularly that control measures specified in this risk assessment document are actually being used in practice. Any specialist emergency or first aid procedures should be specified here. Emergency procedures: First Aid: Electric shock: In the event of an accident phone 62322 and seek assistance from a first aider. Switch off power, if safe to do so. Secure release from contact. Send for a doctor or ambulance. Place the casualty in the recovery position. If casualty not breathing, commence respiratory resuscitation immediately. Biological Agent: Wash any contaminated skin, conjunctivae or mucous membrane immediately. In the event of a wound, it should be allowed to bleed by vigorous irrigation under running water. Seek medical Advice and contact University Occupational Health Service immediately. Spillage: All spillages and surface contamination must be immediately cleaned up and removed including decontamination with a suitable validated disinfectant, such as 10% solution of Trigene. Chemical spill: Eyes: Wash with copious amount of water for at least 15 minutes, phone 62322 and seek assistance from a first aider and seek medical attention. Skin: Wash with copious amount of water, remove contaminated clothing, phone 62322 and seek assistance from a first aider and seek medical attention. Inhalation: If inhaled, phone 62322 and seek assistance from a first aider and seek medical attention. Remove victim to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. If any Standard Operating Procedure (SOP) is required, please specify it here or attach it to this form. Any specialist training required should also be specified here. Attached Is special monitoring (e.g. hearing test, eye test, health surveillance) required? If so, please enter details and also contact the University Occupational Health Service. What personal protective equipment (PPE) is required (e.g. overalls, gloves, respiratory protection, eye protection)? You must ensure that any PPE specified is suitable for the purpose. None Gloves Safety Glasses Please complete this section to confirm that this constitutes a suitable and sufficient assessment of risk. Name of assessor: Signature: Date: Name of supervisor: Signature: Date: Anna Petrunkina010915 Harrison/ Simon McCallum This assessment should be reviewed regularly (usually every 12 months), or earlier if there is a material change to the process, the equipment, location or relevant safety technologies. It should also be reviewed when new people are involved, or after an accident or incident has taken place. Reviewed by (name) Signature Date Indicate changes here5 1 A list of hazards is provided below to help you, but this may not be exhaustive. If any of these hazards can be eliminated altogether, or can be reduced at source by making an inherent change then we must consider doing so. Hazards in bold will also need an additional, more technical assessment on a specialist form - please ask your Departmental Safety Officer or the University Health and Safety Office for further advice. High or low temperatures High pressures Chemical hazards Biological hazards Genetically Modified Organisms Ionising radiations Lasers Sharp objects Dusts Work at heights Animal houses Magnetic fields Machinery hazards Electricity Manual Handling Noise Vibration Falling objects Collapsing structures Flooding Slips, trips and falls Asphyxiant gases Flammable gases 2 Please explain how an accident, incident or health condition could arise. We must consider all events which are reasonably foreseeable. 3 Please see the health and safety risk assessment handbook for further guidance on levels of risk. 4 When deciding on suitable control measures, you should ensure that you are complying with all relevant University policy and guidance documents, and that you have considered the hierarchy of control measures. In order to comply with legislation, we must also take all steps which are ‘reasonably practicable’ to reduce risk. This means that we should take all steps which are (in terms of time, cost and trouble) reasonable in relation to the reduction of risk achieved. 5 If changes are extensive, you will need to complete a whole new form, or attach a written amendment. If there are no changes say so