retrofit to agrium`s special standard surge bin improves

advertisement

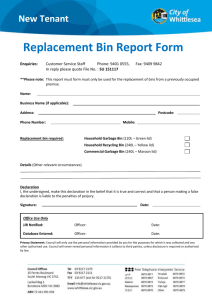

RETROFIT TO AGRIUM’S SPECIAL STANDARD SURGE BIN IMPROVES: RELIABILITY, SAFETY, & LIFE CYCLE COST T Holmes1, S Davison2 1. Jenike & Johanson Ltd. Toronto, ON, Canada tracyh@jenike.com 2. Agrium Inc. Vanscoy, SK, Canada Shawn.Davison@agrium.com ABSTRACT The Special Standard Surge bin at Agrium’s Vanscoy Potash Operations has been plagued with flow, wear, and corrosion issues for it’s entire working life. Investigation showed that the carbon steel construction, bin geometry, and resultant funnel-flow pattern were directly responsible for production losses and disproportionate maintenance and capital costs. Potash enters this bin at 160°C, but the stagnant potash outside the active flow channel was much cooler and moisture migrated toward the outer regions, which caused corrosion of the walls and reduced live capacity as the potash in this area hardened and built up on the walls over time. A 2013 inspection revealed holes and paper-thin wall sections in the cone. The only thing preventing major leaks and potentially even a catastrophic failure was the buildup of stagnant hardened product on the cone walls. Conclusion: “The cone had reached the end of its life and required replacement”. Agrium’s original plan was to replace the cone in kind; however, a failure-mode and bin performance investigation combined with a life-cycle-cost analysis indicated it would be better to redesign the hopper. For success in retrofit projects, it is essential at the design stage to consider the bulk solid flow properties and the operating environment involved.. Because education in this area is not offered at a university level, engineers often do not fully appreciate the effects of the flow properties of bulk solids on bulk material handling equipment. After the modifications, Agrium’s Surge bin provides safer, more reliable operation with a much longer predicted working life. Using this retrofit as an example, we aim to provide a general understanding of bulk solids flow theory and highlight the importance of customizing the design to the appropriate flow properties in the cost effectiveness, reliability, and safety of a bulk material handling system. KEYWORDS bulk material handling, retrofit, cost effective, safety, reliable flow, solids flow theory, flow properties, failure