Storage - Pesticide Safety

advertisement

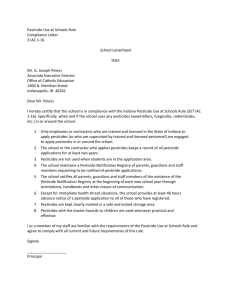

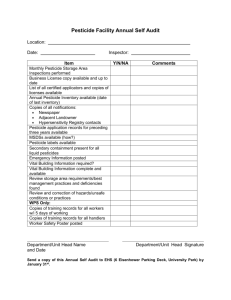

Introduction Pesticide Storage Storing pesticides properly protects human and animal health, safeguards wells and surface waters, and prevents unauthorized access to hazardous chemicals. Proper pesticide storage and inventory practices will prolong the shelf-life of pesticides and make it easier to track your pesticide usage so that you can plan purchases for future years. Reducing the amount of pesticide you store lowers the risk of chemical fires, explosions, or spills that contaminate well water, surface water or the soil. Make every effort to limit storage by buying only the amount of pesticide that you need for a specific job or for the current growing season. Purchase pesticides in refillable containers that can be returned if this can be arranged with your pesticide dealership. The pesticide label is the best guide to storage requirements for every product. The Material Safety Data Sheet (MSDS) provides additional information on normal appearance and odor as well as flash point, fire control recommendations, boiling point, and solubility. Labels and Material Safety Data Sheets for most pesticides are available on-line at http://www.cdms.net and http://www.greenbook.net REFERENCES CITED: Store Pesticides Safely, Pesticide Information Program Information Sheet, PIP37. R.G. Bellinger. Sept. 2001. Clemson University Cooperative Extension Service. http://entweb.clemson.edu/pesticid/saftyed/PIP37sto.pdf. Pesticide Storage Facilities, FS603. G. M. Ghidiu and G. C. Hamilton. Aug. 2001. Rutgers Cooperative Research & Extension. http://www.rcre.rutgers.edu/pubs/publication.asp?pid=FS603 Compiled Introduction Pesticide Storage Storing pesticides properly protects human and animal health, safeguards wells and surface waters, and prevents unauthorized access to hazardous chemicals. Proper pesticide storage and inventory practices will prolong the shelf-life of pesticides and make it easier to track your pesticide usage so that you can plan purchases for future years. Reducing the amount of pesticide you store lowers the risk of chemical fires, explosions, or spills that contaminate well water, surface water or the soil. Make every effort to limit storage by buying only the amount of pesticide that you need for a specific job or for the current growing season. Purchase pesticides in refillable containers that can be returned if this can be arranged with your pesticide dealership. The pesticide label is the best guide to storage requirements for every product. The Material Safety Data Sheet (MSDS) provides additional information on normal appearance and odor as well as flash point, fire control recommendations, boiling point, and solubility. Labels and Material Safety Data Sheets for most pesticides are available on-line at http://www.cdms.net and http://www.greenbook.net REFERENCES CITED: Store Pesticides Safely, Pesticide Information Program Information Sheet, PIP37. R.G. Bellinger. Sept. 2001. Clemson University Cooperative Extension Service. http://entweb.clemson.edu/pesticid/saftyed/PIP37sto.pdf. Pesticide Storage Facilities, FS603. G. M. Ghidiu and G. C. Hamilton. Aug. 2001. Rutgers Cooperative Research & Extension. http://www.rcre.rutgers.edu/pubs/publication.asp?pid=FS603 Compiled Storage Conditions Wayne Buhler Storage Conditions Most pesticide labels call for storage in a "cool, dry" place. For your safety, always provide adequate ventilation and light. Temperature. The temperature inside the storage area should not get below 40 F or over 100 F. Some pesticides will freeze when they get too cold and the container may crack and leak. Freezing temperatures may cause some formulations to separate. Some pesticides expand when they get very hot. High temperatures also cause plastic to melt or become brittle and may cause a build up of pressure that may break glass containers or cause the chemicals to volatilize or spill out when the container is opened. Excessive heat may cause explosion or fire. Exhaust fans will reduce temperatures. Minimize fire hazards if you provide supplemental heating to the storage area. Humidity. Keep the storage area dry. High humidity causes some dry formulations to cake, clump, breakdown, or dissolve, and release pesticide, making them unusable and dangerous. Humidity also weakens paper and cardboard containers, and will eventually rust metal containers. It may cause labels to peel off or become unreadable. Ventilation. The storage building needs constant ventilation to prevent the buildup of toxic fumes and to reduce humidity. Install louvered air intake vents low on the wall with the entrance door or in the lower part of the door and an exhaust fan or louvered air vents high on the opposite wall. This allows vapors to flow away from anyone entering or inside the storage unit and provides a continuous flow of air when the door is open. An exhaust fan removes fumes, excess heat, and humidity better than passive airflow. Vent exhaust air from the storage room directly to the outside. Do not exhaust the air from a storage area into other rooms. Ventilation may be reduced in the winter so heat can be added to maintain 40oF in the storage facility. Light. Make sure the storage area is bright enough so that pesticide labels can be read easily. Do not store pesticides in direct sunlight because exposure to sunlight may cause pesticides to break down and become unusable. Compiled by Dr. Wayne Buhler Storage Safety and Security Wayne Buhler Storage Safety and Security Secure the building and storage site. Only you and your authorized employees should have access to the storage area. Keep the storage unit locked at all times, except when it is under the direct supervision of a person authorized for entry. For extra security, install a fence around the storage area and lock the gate. Consider installing security lighting and an alarm system. Basic Safety Guidelines: Never let anyone eat, drink, or smoke in the storage facility. Store pesticides in their original, labeled containers. Never store pesticides in milk jugs, soft drink bottles, fruit jars, or medicine bottles. Do not store pesticides with or near food, medicine, cleaning supplies, fertilizers, seed, or animal feed. Do not keep gasoline, kerosene, or other combustible materials with the pesticides. Make sure pesticides are not kept near operations which present a fire hazard such as burning and welding. Do not leave any pesticide container in full sun or next to a heater. Store pesticides on metal shelves with a lip or on wood shelves covered with plastic or chemically-resistant epoxy paint. Leak-proof plastic trays on shelves work well. Do not store pesticides on the floor. Use pallets under large containers/bags. Keep the storage area neat and clean at all times. Keep the area free of debris such as waste paper, rags, or used cardboard boxes, which may provide an ignition source. Clean up any spills immediately. Store dry formulations on the highest shelves. Store liquids and glass containers on the lowest level. This will prevent contamination in case a liquid container leaks. Warning/Emergency response signs. Place signs indicating "Danger PesticidesKeep Out- No Smoking" at all storage entries. Consider posting signs in a second language, such as Spanish. Some state laws require additional signage indicating who is responsible for the pesticide storage and who to call for emergencies. This type of sign should have at least two emergency phone numbers: the owner should not be the sole contact in an accident. The National Fire Protection Association (NFPA) 704 standard provides a way to communicate the potential hazards of storing hazardous chemicals through the posting of a diamond shape or square-onpoint shape sign. The sign addresses the health, flammability, instability and related hazards associated with short-term exposures that are most likely to occur as a result of fire, spill, or similar emergency. The 704 standard is applicable to industrial, commercial, and institutional facilities that manufacture, handle, or store hazardous materials. For more details on this standard, refer to the following Web site: http://www.nfpa.org/faq.asp?categoryID=928. Inventory. Keep an up-to-date written inventory of all stored pesticides and save a copy in a place away from the storage area. Some states require that this inventory list be updated annually and sent to the local fire department (see Plan for Emergencies). The inventory is very useful in a fire and flood emergency, in settling insurance claims, and in estimating future pesticide needs. Separation. Read the label or MSDS to find out whether a product interacts with other materials and should be stored separately. Consider storing volatile herbicides, especially some types of 2,4-D, separately from other pesticides. Compiled by Dr. Wayne Buhler Container Care Wayne Buhler Container Care Make sure the label on every container is clearly visible and readable. If the label gets fragile or is destroyed, mark the container in permanent ink with the trade name and common name of the product, the EPA registration number, the percentage of each active ingredient, the signal word (Caution, Warning, or Danger), and the use classification (restricteduse or general-use pesticide). Your state may require different information on containers lacking labels (See Laws and Regulations link). You may request a replacement label from a pesticide dealer or manufacturer. Consider covering the label with transparent wrapping tape to protect it. Write the date of purchase on all containers. Use older pesticides first so that a disposal problem is not created with pesticides stored longer than their shelf life. If you have questions about the shelf life of a product, contact the dealer or manufacturer. Conduct regular inspections of the storage facility and check containers for cracks, leaks, and deterioration. If a container is damaged, you may use the pesticide immediately for uses specified on the label or transfer it using one of the following procedures and wearing appropriate protective clothing and equipment. 1. Transfer the pesticide into another container that originally held the same pesticide and that still has its label. 2. Transfer the pesticide to a sturdy container that can be tightly closed. If possible, transfer the label from the damaged container to the new one or make a temporary label (see minimum label requirements listed above) until you can get a new one. Never use a food, feed, or drink container. 3. Place the damaged container and its contents into a larger liquidproof container. Make a temporary label until you can use the pesticide or dispose of it properly. Compiled by Dr. Wayne Buhler Plan For Emergencies Wayne Buhler Plan for Emergencies In addition to keeping an up-to-date inventory of stored pesticides, it is a good idea to have a plan for handling spills, fires, explosions, or other emergencies. Make sure workers are trained on how to keep the storage area safe and secure, and how to respond to spills or other accidents. Post emergency telephone numbers nearby and make sure workers know where these numbers are. Stock each storage site with an immediate supply of clean water and soap in case of pesticide contact with skin. If running water is not practical, use a large sealable container with clean water. Change the water at least once a week so that it is safe to use on skin and eyes. Keep an eye-wash dispenser immediately available for emergencies. Responding to spills: Keep emergency supplies and personal protective equipment nearby, but not in the storage building or room. You may need a respirator, gloves, eye protection, boots, and a protective suit before entering the storage area, particularly if a spill or other accident has occurred. Keep spill cleanup materials nearby. A spill kit should include absorptive materials such as nonchlorinated cat litter, vermiculite, or activated charcoal, a shovel, and a drum with a lid for storing contaminated material. Don't allow workers to take items from the kit for other purposes. A clean, empty pesticide container may be used to capture any pesticide that has not leaked from a broken container. Make sure this is labeled appropriately before returning it to storage. Refer to the MSDS for the types of materials that are needed to deactivate spills. Common decontamination materials include hydrated lime, lye, ammonia, bleach, or detergent. Do not mix ammonia with bleach. Call CHEMTREC (Chemical Transportation Emergency Center, 1-800424-9300) or the chemical manufacturer for information on responding to large spills. Federal and state laws require reporting of spills involving pesticides that are regulated as Hazardous Substances or as Extremely Hazardous Substances. Not all pesticides meet these criteria. Pesticides that are on these lists have reporting requirements based on the amount of active ingredient spilled, referred to the Reportable Quantity (RQ). When in doubt, contact the appropriate agency (see Laws and Regulations). Documents to keep on file: Keep copies of your storage location map, storage unit floor plan, and current or seasonal inventory in a secure place away from the storage unit. Keep copies of labels and MSDSs for every chemical in storage. Work with emergency responders: Notify local fire departments or other first responders about the location and contents of your pesticide storage facility. You may be required to notify your Local Emergency Planning Committee (LEPC) about the contents of your storage building. Large-scale commercial storage or restricted use pesticide storage facilities should have written contingency plans describing the procedures for managing fires involving pesticides. A document entitled "Fire and Spill Emergency Pre-Plan for Handling Agricultural Chemicals" is available at: http://ipm.ncsu.edu/pesticidesafety . The plan provides grids for drawing the property site and drainage routes, list of emergency contacts, fire fighting tactics and location of available resources. Update the plan yearly and review it with your local Fire Department. Fire extinguishers: Keep a fire extinguisher that is approved for chemical fires nearby, or near each exit within the storage building. Read the labels to determine what type of fire extinguisher(s) you may need. ABC classified extinguishers are appropriate for most pesticides. Fire extinguishers need to be inspected and maintained on a regular basis to ensure that they are in good operating condition. For information on the appropriate size, type, and inspection of fire extinguishers for your pesticide storage facility, read the following fact sheet: Use, Placement, Maintenance and Testing of Portable Fire Extinguishers. Lab Safety Supply, EZfacts document number 135, http://www.labsafety.com/refinfo/ezfacts/ezf135.htm. Remember that it is sometimes safer to let a chemical fire burn itself out than to expose fire fighters to pesticides or to contaminate large quantities of water. Compiled by Dr. Wayne Buhler Laws and Regulations Wayne Buhler Storage Laws and Regulations For information about state-specific storage regulations, contact your state pesticide regulatory agency by visiting the on-line directories of either the Association of American Pesticide Control Officials (AAPCO) or the National Pesticide Information Center (NPIC). You can call AAPCO at 1302-422-8152, or NPIC at 1-800-858-7378. Fact Sheets Wayne Buhler Pesticides and Their Proper Storage. F. Whitford, A. Martin, J. Boyer, and A. Blessing. Purdue Pesticide Programs PPP-26. http://www.btny.purdue.edu/pubs/PPP/PPP26.html Pesticides and Container Management. 2006. F. Whitford, A. Martin, and J. Becovitz. http://www.btny.purdue.edu/Pubs/PPP/PPP-21.pdf Storage and Display of Retail Pesticides. 2006. Lt. Col. Terry L. Carpenter. Armed Forces Pest Management Board. Technical Guide No. 45. http://www.afpmb.org/pubs/tims/TG45/TG45.htm Pesticide Storage, Handling and Application (On-line training manual). 2004. Ontario Ministry of Agriculture, Food and Rural Affairs. http://www.omafra.gov.on.ca/english/environment/pesticide/psha.htm Store Pesticides Safely, Pesticide Information Program Information Sheet, PIP-37. R.G. Bellinger. Sept. 2001. Clemson University Cooperative Extension Service. http://entweb.clemson.edu/pesticid/saftyed/PIP37sto.pdf. Pesticide Storage Facilities, FS603. G. M. Ghidiu and G. C. Hamilton. Aug. 2001. Rutgers Cooperative Research & Extension. http://www.rcre.rutgers.edu/pubs/publication.asp?pid=FS603 Compiled by Dr. Wayne Buhler Storage Checklist Pesticide Storage Checklist (pdf) A useful one-page storage checklist for printing. Wayne Buhler Pesticide Storage Checklist Inspect your pesticide storage area regularly. If you answer “no” to any statements below, take immediate steps to correct the situation. Date of Inspection: ___________ Safety Storage room locked. Storage area signs posted with emergency contact information. No Smoking signs posted. Personal protective equipment stored nearby. Clean up supplies stored nearby. Inventory is up to date and stored separately. _________ __________ Yes No Yes No Yes No Labels and MSDS on file Fire extinguisher in good working order Storage Area Ventilation system is working. Area is clean with no debris or combustibles. Floor is clear of spills or leaks. Pesticides stored off floor Storage area contains pesticides only--no feed, fertilizer or other materials. Container Inspection Labels readable and attached to containers. Containers marked with purchase date. Dry formulations stored above liquids. Container caps are tightly closed. Used containers are rinsed and punctured. Adapted from “Pesticides and Their Proper Storage” Purdue Pesticide Publication PPP-26 Storage Assessment Wayne Buhler Read all the statements in each set and select the one that best describes your storage conditions. The responses, in order from first to last, have a high, medium, or low (zero or negative) point value. Your goal is to score the highest number of points (maximum = 26) by applying as many low risk practices as you can. 1. You usually store: _____ no more than 1 gallon or 10 pounds of each pesticide. (2) _____ more than 1 gallon or 10 pounds, but less than 55 gallons or 50 pounds of each pesticide. (1) _____ more than 55 gallons or 50 pounds of each of several pesticides. (0) 2. Your pesticide storage area: _____ is a roofed building with a waterproof (sealed or coated) concrete floor and curb to contain leaks and spills. (2) _____ is roofed with a concrete floor and no curb (1) _____ has a gravel or dirt floor or it is in the open. (-1) 3. Your pesticide storage area: _____ has an active (electrical) ventilation system. (2) _____ has a passive ventilation system (holes or vents to provide cross ventilation). (1) _____ has no ventilation. (-1) 4. Your pesticide storage area: _____ is more than 100 feet (horizontally) from a public water supply or surface waters and more than 50 feet from a private water supply well. (2) _____ is within 100 feet of a public water supply or surface waters or within 50 feet of a well. (1) _____ is in your well house or in a facility containing an unsealed well. (0) 5. Your pesticide storage area: _____ is locked or secured and separated from other activities (2) _____ is secured, but sometimes open to activities that could damage containers or spill pesticides. (1) _____ is not secure and is open to theft, vandalism, and children or other unauthorized persons. (-1) 6. Your pesticide storage area: _____ is used for pesticides only. (2) _____ is sometimes also used for seed, fertilizer or other nonfood/nonfeed products. (1) _____ is used to store human food or animal feed products. (-1) 7. Unusable or cancelled pesticides: _____ are kept separately in the pesticide storage area until safe disposal through your state’s pesticide disposal assistance program. (2) _____ are kept with other pesticides in clearly marked containers. (1) _____ are buried on the farm or dumped off the property. (-1) 8. Your pesticides are: _____ in plastic or metal containers. Containers in poor condition are placed inside another liquid-proof container. (2) _____ in some metal containers that are deteriorating. (1) _____ in metal containers with holes or weak seams that may leak or are stored in containers that have previously been used for food, feed, beverages, or medicine. (-1) 9. You have pesticides: _____ stored in clearly labeled original containers. (2) _____ that have been transferred to another container with the following labeling information: common chemical name, percentage of each active ingredient, EPA registration number, signal word (Caution, Warning or Danger), and use classification (restricted-use or general-use). (1) 10. Pesticides are: _____ store with liquids on lower shelves below dry pesticides and herbicides separated from insecticides and fungicides. (2) _____ store with liquids below dry pesticides, but there is no separation of herbicides from insecticides and fungicides. (1) _____ store without sorting for liquids or type of pesticide. (0) 11. Your pesticide storage area has: _____ warning signs posted on all entrances to the storage area which read “Danger – Pesticide – Keep Out – No Smoking” (or similar wording). (2) _____ warning signs posted, but they have become weathered and are difficult to read. (1) _____ no warning signs. (0) 12. Your local fire authorities: _____ have a copy of your pre-fire plan for handling agricultural chemical fires at your storage area. (2) _____ are aware of your pesticide storage facility. (1) _____ do not know about your pesticide storage facility and have not visited your site. (0) 13. Your inventory of pesticides in storage: _____ is up-to-date, has Material Safety Data Sheets (MSDS) for each product, and is kept at a central location. (2) _____ is not kept up-to-date (pesticides placed in storage in the last 6 mos. to a year are not recorded). (1) _____ is out-of-date or does not exist. (0) Storage Education Module Wayne Buhler Test your knowledge of pesticide storage by choosing the best option to complete each statement or answer a question below. The correct choices are given below the final question. 1. A practical temperature range to maintain inside pesticide storage facilities is: a. 60 to 80o F b. 40 to 100o F c. 30 to 90o F d. 50 to 110o F 2. The best way to store pesticides is in: a. any empty pesticide container b. glass bottles c. any unbreakable container d. the original, labeled container 3. Which of the following is the LEAST important reason for proper ventilation of pesticides in storage? a. it prevents pests from entering the facility b. it prevents the buildup of vapors c. it helps reduce temperature and humidity in warm months d. it helps to preserve labels on pesticide containers 4. A pesticide storage facility should be: a. at least 50 feet from a wellhead. b. always located at the top of a hill to prevent flooding. c. always in the basement. d. located upwind from animal feeding stations. 5. The floor of a pesticide storage facility should be: a. unfinished wood because it is easier to sweep up spills. b. compacted soil c. concrete, plastic, or epoxy covered metal. d. made of any material since pesticides are stored on pallets and not directly on the floor. 6. Pesticide storage buildings should be well-ventilated, lighted, and protected from ___________ extremes. a. pH b. solar c. temperature d. moisture 7. When a pesticide label gets unreadable: a. throw the container away following state regulations for proper disposal. b. write the important information on the container with a permanent marker. c. request that the pesticide company send you new product. d. use the pesticide immediately. 8. Writing the date of purchase on all pesticide containers is useful because a. you can always use the freshest product for maximum control. b. it fulfills Federal labeling laws. c. it helps you track inventory. d. you can use the oldest material before it goes out of date. 9. Putting warning signs on the entrance to a pesticide storage facility is: a. a bad idea because kids might get curious about the chemicals and might break in. b. a good idea to protect firefighters or emergency workers in case of a fire. c. required by Federal law. d. a bad idea because it would upset environmentalists who might take you to court. 10. It is a good idea to ventilate pesticide storage facilities a. constantly. b. ten minutes before entering the area. c. just in the summer to prevent overheating. d. not during the winter to keep liquid formulations from freezing. 11. Portable buildings used for pesticide storage a. are a good idea because you can carry them from place to place. b. should be securely anchored using tie-downs of some sort. c. don’t need warning signs since most of them are blue. d. are not adequately ventilated. 12. Baits for rodents, birds, slugs, or insects a. should be stored away from other pesticides. b. always should be stored on a bottom shelf or on the floor. c. are harmless to humans so they can be kept in the home or office. d. should be kept in full sun or next to a heater to keep them from clumping. 13. Which of the following is NOT a good method to determine if a pesticide kept in storage for a long time is still effective? a. contact the manufacturer b. test a small amount by applying it to a labeled site c. look for changes in color or consistency d. open container and breathe in vapors. Answers: 1) b, 2) d, 3) a, 4) a, 5) c, 6) c, 7) b, 8) d, 9) b, 10) a, 11) b, 12) a, 13) d Storage slide presentation Pesticide Storage Slide presentation Open this slide presentation in PowerPoint View a PowerPont slide presentation with notes on proper pesticide storage practices (click on link in summary box to the right).