1 Multiple Choice (select the best answer) 1 points In 2D mode

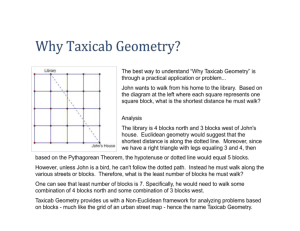

advertisement

1 Multiple Choice (select the best answer) 1 points In 2D mode, geometry is created at the z position selected By using the AutoCursor to select a position for the entity Parallel to the current Cplane at the current system Z depth All of the above 2 Multiple Choice (select the best answer) 1 points Which of the following entities can define a Construction plane 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc with center point, a 2D spline 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc, a flat surface, 3 points 3 Multiple Choice (select the best answer) 1 points Define Fillet An line tangent to two arcs An arc tangent to two entities An arc connected to two entities All of the above 4 True/False (select one answer) 1 points Tangent arcs may not be created on an extended portion of the selected entity True False 5 True/False (select one answer) 1 points All basic geometry can be created through the Sketcher toolbar True False 6 True/False (select one answer) Arcs may not be created on an extended portion of the 1 points selected entity. True False 7 Multiple Choice (select the best answer) 1 points The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? Style Definition Attributes All of the above 8 True/False (select one answer) 1 points General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. True False 9 Multiple Choice (select the best answer) 1 points After using the Xform function, what are the red entities called? Result Group Done None of the above 10 Multiple Choice (select the best answer) 1 points Press F9 to: Show coordinate axes Show/hide the coordinate axes and system origin Show/hide Coordinate information Show/hide Zero 11 Multiple Choice (select the best answer) In a top View and Plane, which axis is horizontal? X axis Y axis Z axis 1 points All 12 Multiple Choice (select the best answer) 1 points What are the different Wireframe Chamfering styles? Distance 1, Distance 2, and Angle. Distance, and/or Angle Distance 1, Distance 2, Width, and Angle Width and Angle 13 True/False (select one answer) 1 points To create a parallel line that is tangent to an arc, you click the Tangent button in the line parallel ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. True False 14 Multiple Choice (select the best answer) 1 points In the Xform Rotate function, the angle is calculated Relative to the horizontal axis At 3:00 in the Top view At 3:00 in the current construction plane All of the above 15 Multiple Choice (select the best answer) 1 points Setting a new active WCS, Cplane, and Tplane in the View Manager. Rotates the part with the CNC Rotary axis Maps the axis to the desired plane as if rotating a part by hand Changes the current view of the part Sets axis combinations using geometry 16 Multiple Choice (select the best answer) In 3D mode, geometry is created At various Z depths, unconstrained by the current system Z depth and Cplane setting By using AutoCursor to select a position or otherwise specify the X, Y, and Z values for the entity By placing the first sketched point at the default Z depth 1 points At all of the geometry positions listed above 17 Multiple Choice (select the best answer) 1 points Which one of the following Trim function buttons is not mutually exclusive? Trim to point Divide Default Length 18 Multiple Choice (select the best answer) 1 points In a Top view and plane, which axis is vertical parallel to? X axis Y axis Z axis All of the above 19 Multiple Choice (select the best answer) 1 points Where do full arcs start and end? 12:00 3:00 6:00 9:00 20 Multiple Choice (select the best answer) 1 points Which is not a typical task of the View Manager? Selecting which views to use for the Cplane, Tplane, or the work coordinate system Editing the origin of a view Changing the Gview All of the above 1: multiple choice In 2D mode, geometry is created correct answer. 2: multiple choice Which of the following entities can define a Construction plane correct answer. 3: multiple choice Define Fillet correct answer. 4: true/false Tangent arcs may not be created on an extended portion of the selected entity correct answer. 5: true/false All basic geometry can be created through the Sketcher toolbar correct answer. 6: true/false Arcs may not be created on an extended portion of the selected entity. correct answer. 7: multiple choice The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? correct answer. 8: true/false General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. correct answer. 9: multiple choice After using the Xform function, what are the red entities called? Incorrect answer. 10: multiple choice Press F9 to: correct answer. 11: multiple choice In a top View and Plane, which axis is horizontal? correct answer. 12: multiple choice What are the different Wireframe Chamfering styles? correct answer. 13: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line parallel ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. correct answer. 14: multiple choice In the Xform Rotate function, the angle is calculated Incorrect answer. 15: multiple choice Setting a new active WCS, Cplane, and Tplane in the View Manager. correct answer. 16: multiple choice In 3D mode, geometry is created correct answer. 17: multiple choice Which one of the following Trim function buttons is not mutually exclusive? correct answer. 18: multiple choice In a Top view and plane, which axis is vertical parallel to? Incorrect answer. 19: multiple choice Where do full arcs start and end? correct answer. 20: multiple choice Which is not a typical task of the View Manager? correct answer. Total Score: 1 Multiple Choice (select the best answer) What are the steps to optimize existing drill point locations? Select points in the correct order Select the Drill Point Manager, select Sort options, select Sort method Select the Drill Point Manager, right-click, select Sort options, select Sort method, click OK Select the operation, right-click, select Sort 17 / 20 1 points options, click OK 2 Multiple Choice (select the best answer) 1 points The Remachining Toolpath selection is used for: Machining the stock left over from a large tool with a smaller tool Correcting missed dimensions after measuring cut part Obtaining a much finer finish on a part Correcting errors after a broken tool 3 Multiple Choice (select the best answer) 1 points To create a setup sheet for toolpath operations, you select the operations and: Left-mouse click, select Setup sheet Right-mouse click, select Setup sheet Middle-mouse click, select Setup sheet Write the process using Notepad 4 Multiple Choice (select the best answer) 1 points Toolpath verification is very important in NC programming for which of the following reason? Reduce costs Simulate graphically the machining of the part programs Detect potential errors in the part programs before they are used in try out run All of the above 5 Multiple Choice (select the best answer) 1 points Which one of the following stop options is found in the verify function? Stop on collision Stop on tool changes Stop after each operation All of the above 6 Multiple Choice (select the best answer) When you set a new Tool Plane, you are: Orientating the part, not using the machine axis Setting zero 1 points Orientating the part, using machine axis All of the above 7 True/False (select one answer) 1 points Chaining a rectangle CW with the cutter comp set to left will cut the inside of the rectangle. True False 8 True/False (select one answer) 1 points Chaining a circle CCW with the cutter comp set to left will cut the outside of the circle. True False 9 Multiple Choice (select the best answer) 1 points When you chain geometry for a pocket with islands, the correct chaining method is which of the following? Select island tops and pocket top Select island bottom and pocket bottom Select island bottom and pocket top Select pocket bottom and island top 10 Multiple Choice (select the best answer) 1 points Which of these is not a toolpath compensation type? Wear Computer Radial Control 11 Multiple Choice (select the best answer) 1 points Lead In/Out moves are: A combination of lines and arcs at the beginning and end of a toolpath that control how the tool An extra move to allow cutter compensation to turn on and off prior to cutting material An extra move to set tool deflection and eliminate dwell moves from the start and end of a cut All of the above 12 Multiple Choice (select the best answer) 1 points When you chain a contour and it does not chain completely around the part, which of the following is not the possible cause? A gap or break in the geometry path Duplicate geometry entities A reversed normal Seemingly connected geometry that includes entities at varying Z depths 13 Multiple Choice (select the best answer) 1 points Which of these is not a standard WCS selection? Geometry Normal Isometric None of the above 14 Multiple Choice (select the best answer) 1 points How does Mastercam control roughing profile cuts? Percentage of the tool or distance Spacing Tolerance setting All of the above 15 Multiple Choice (select the best answer) 1 points What are the two types of contours? Round and square Open and closed Outside and inside None of the above 16 Multiple Choice (select the best answer) 1 points Which of these roughing options moves the tool in a linear motion according to the roughing angle? Zig Zag High Speed Morph All the above 17 Multiple Choice (select the best answer) 1 points When verifying a pocket island machining toolpath, you notice that some material has been left. To correct this you should first try: Decreasing the stepover amount for the tool Changing the size of the tool to a much smaller tool Selecting a different type of toolpath Changing material size 18 Multiple Choice (select the best answer) 1 points To produce a chamfer contour, you must: Enter depth of chamfer and angle of tool Chain the outside of the contour, enter chamfer width and tip offset Chain the inside geometry of chamfer, ignore the depth Chain the bottom of the geometry of the chamfer, ignore the tool diameter 19 Multiple Choice (select the best answer) 1 points When you highlight a new plane and select the “=” button in the , you are: Orientating the part, using machine axis Orientating the part, not using the machine axis Setting zero None of the above 20 Multiple Choice (select the best answer) If a contour toolpath is on the wrong side of the centerline, which of the following does not correct the problem? Changing the compensation type to wear Changing the compensation direction Using the Chain Manager to reverse chain direction Re-chaining the geometry, selecting the first element as before but at the opposite end from wher 1: multiple choice What are the steps to optimize existing drill point locations? correct answer. 2: multiple choice The Remachining Toolpath selection is correct answer. 1 points used for: 3: multiple choice To create a setup sheet for toolpath operations, you select the operations and: correct answer. 4: multiple choice Toolpath verification is very important in NC programming for which of the following reason? correct answer. 5: multiple choice Which one of the following stop options is found in the verify function? correct answer. 6: multiple choice When you set a new Tool Plane, you are: Incorrect answer. 7: true/false Chaining a rectangle 8: true/false Chaining a circle CCW 9: multiple choice When you chain geometry for a pocket with islands, the correct chaining method is which of the following? correct answer. 10: multiple choice Which of these is not a toolpath compensation type? correct answer. 11: multiple choice Lead In/Out moves are: correct answer. 12: multiple choice When you chain a contour and it does not chain completely around the part, which of the following is not the possible cause? correct answer. 13: multiple choice Which of these is not a standard WCS selection? correct answer. 14: multiple choice How does Mastercam control roughing profile cuts? correct answer. 15: multiple choice What are the two types of contours? correct answer. 16: multiple choice Which of these roughing options moves the tool in a linear motion according to the roughing angle? correct answer. 17: multiple choice When verifying a pocket island machining toolpath, you notice that some correct answer. CW with the cutter comp set to left will cut the inside of the rectangle. with the cutter comp set to left will cut the outside of the circle. correct answer. correct answer. material has been left. To correct this you should first try: 18: multiple choice To produce a chamfer contour, you must: Incorrect answer. 19: multiple choice When you highlight a new plane and select the “=” button in the , you are: Incorrect answer. 20: multiple choice If a contour toolpath is on the wrong side of the centerline, which of the following does not correct the problem? correct answer. Total Score: 1 17 / 20 True/False (select one answer) 1 points Changing entry methods for dynamic mill toolpath doesn’t affect the tool motion all that much. True/False True False 2 True/False (select one answer) 1 points Mastercam always sets the Depth value to zero (0.0) in the Linking Parameters page. True False 3 Multiple Choice (select the best answer) 1 points Which Peel mill toolpath parameter do you change to ease the tool gradually into the material, rather than engaging it fully on the first cut? Entry settings on the Lead In/Out page. Feed plane on the Linking Parameters page. Extend entry on the Cut Parameters page. None of the above. 4 True/False (select one answer) When you choose the medial entry method, Mastercam calculates a ramp entry along the medial axis (central spline of the pocket) and begins the toolpath along that axis. True 1 points False 5 Multiple Choice (select the best answer) 1 points What does the following message mean? “Blend mill does not (yet) compensate blend chains for tool” Tool tip compensation is yet not available for 2D High Speed Blend mill toolpaths. The tool is not offset from the chained geometry. Mastercam drives the tool centerline along the contour geometry. At this point in the toolpath generation, Blend mill has not yet compensated the blend chains for the tool, but it will when you post the operation. None of the above 6 Multiple Choice (select the best answer) 1 points How do you activate thin wall cutting in a dynamic milling toolpath? Select Optimize cut order within pocket in the Cut Parameters page. Activate Depths cuts and select the Tapered walls check box. Then define the angle. You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (remachining). You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (finishing). 7 Multiple Choice (select the best answer) 1 points Mastercam applies the Additional slot width distance you define in the Entry Motion page for a Custom entry method by: Setting the entire entry slot width equal to the specified distance. Adding half of the specified distance to each side of the tool diameter to define the total entry slot width. Adding the entire specified distance to each side of tool diameter to define the total entry slot width. All of the above 8 True/False (select one answer) 1 points You can set the helical entry position to a specific point. True False 9 Multiple Choice (select the best answer) 1 points What is the difference between 2D high speed toolpaths and traditional 2D Mastercam toolpaths? You need a high speed CNC machine to run 2D high speed toolpaths. 2D high speed toolpaths generate a sweeping tool motion that reduces load on the tool and spindle, as compared to traditional 2D toolpaths. 2D high speed tool motion is based on entry method and starting location. Traditional tool motion is based on geometry offsets. Answers b and c 10 True/False (select one answer) 1 points Activating Microlift on back moves (Cut Parameters) helps evacuate chips more cleanly and reduce tool temperature during Peel mill cut passes. True False 11 Multiple Choice (select the best answer) 1 points For thin wall milling, a best practice is to set your stepover to: Anything you choose. Less than 75% of the cutter diameter to avoid pulling the tool out of the tool holder. Greater than 75% of the cutter diameter to maintain a smooth cutting motion. None of the above. 12 True/False (select one answer) 1 points There are no chaining requirements for 2D High Speed Dynamic mill toolpaths. True False 13 True/False (select one answer) 1 points 2D high speed Area mill toolpaths require one or more chains. Chains can be open or closed. True False 14 True/False (select one answer) The Custom entry method requires that you first select 1 points an open chain before configuring the toolpath. True False 15 Multiple Choice (select the best answer) 1 points What are the chaining requirements for a 2D High Speed Core mill toolpath? One closed chain that defines the stock boundary. Two closed chains, the outermost chain defines the stock boundary and the innermost defines the toolpath boundary. Supports any number of closed and open chains. The outermost chain defines the stock boundary; Mastercam closes open chains with a straight line. None of the above 16 True/False (select one answer) 1 points 2D High Speed Blend mill toolpaths smoothly transition cut passes between two dissimilar open contours True False 17 True/False (select one answer) 1 points 2D High Speed Peel mill toolpaths require two open chains. True False 18 True/False (select one answer) 1 points The Machine finish passes only at final depths check box must be selected before you can access the Thin wall settings. True False 19 Multiple Choice (select the best answer) What is the best practice for offsetting the tool from the selected contours when configuring a 2D High Speed Blend mill toolpath? Can’t be done. Set the Cutter compensation in the toolpath’s Cut parameters page. 1 points Use Xform, Offset to create new drive geometry. Then chain the offset geometry. None of the above. 20 Multiple Choice (select the best answer) 1 points When using the Profile entry method for dynamic milling toolpaths, Mastercam calculates the entry point based on: The point position selected when chaining the toolpath geometry. Smallest area to machine. Largest area to machine. None of the above. 1: true/false Changing entry methods for dynamic mill toolpath doesn’t affect the tool motion all that much. True/False correct answer. 2: true/false Mastercam always sets the Depth value to zero (0.0) in the Linking Parameters page. correct answer. 3: multiple choice Which Peel mill toolpath parameter do you change to ease the tool gradually into the material, rather than engaging it fully on the first cut? correct answer. 4: true/false When you choose the medial entry method, Mastercam calculates a ramp entry along the medial axis (central spline of the pocket) and begins the toolpath along that axis. correct answer. 5: multiple choice What does the following message mean? “Blend mill does not (yet) compensate blend chains for tool” correct answer. 6: multiple choice How do you activate thin wall cutting in a dynamic milling toolpath? correct answer. 7: multiple choice Mastercam applies the Additional slot width distance you define in the Entry Motion page for a Custom entry method by: Incorrect answer. 8: true/false You can set the helical entry position to a specific point. correct answer. 9: multiple choice What is the difference between 2D high speed toolpaths and traditional 2D Mastercam toolpaths? Incorrect answer. 10: true/false Activating Microlift on back moves (Cut Parameters) helps evacuate chips more cleanly and reduce tool temperature during Peel mill cut passes. correct answer. 11: multiple choice For thin wall milling, a best practice is to set your stepover to: Incorrect answer. 12: true/false There are no chaining requirements for 2D High Speed Dynamic mill toolpaths. correct answer. 13: true/false 2D high speed Area mill toolpaths require one or more chains. Chains can be open or closed. correct answer. 14: true/false The Custom entry method requires that you first select an open chain before configuring the toolpath. Incorrect answer. 15: multiple choice What are the chaining requirements for a 2D High Speed Core mill toolpath? correct answer. 16: true/false 2D High Speed Blend mill toolpaths smoothly transition cut passes between two dissimilar open contours correct answer. 17: true/false 2D High Speed Peel mill toolpaths require two open chains. Incorrect answer. 18: true/false The Machine finish passes only at final depths check box must be selected before you can access the Thin wall correct answer. settings. 19: multiple choice What is the best practice for offsetting the tool from the selected contours when configuring a 2D High Speed Blend mill toolpath? correct answer. 20: multiple choice When using the Profile entry method for dynamic milling toolpaths, Mastercam calculates the entry point based on: correct answer. Total Score: 15 / 20 X5 Lathe Pretest 1 Multiple Choice (select the best answer) 1 points Where do full arcs start and end? 12:00 3:00 6:00 9:00 2 Multiple Choice (select the best answer) 1 points Press F9 to: Show/hide coordinate axes Show/hide the coordinate axes and system origin Show/hide Coordinate information Show/hide Zero 3 True/False (select one answer) 1 points Arcs may not be created on an extended portion of the selected entity. True False 4 Multiple Choice (select the best answer) In 3D mode, geometry is created At various Z depths, unconstrained by the current system Z depth and Cplane setting By using AutoCursor to select a position or otherwise specify the X, Y, and Z values for the entity 1 points By placing the first sketched point at the default Z depth At all of the geometry positions listed above 5 Multiple Choice (select the best answer) 1 points In a top View and Plane, which axis is horizontal? X axis Y axis Z axis All 6 True/False (select one answer) 1 points All basic geometry can be created through the Sketcher toolbar True False 7 True/False (select one answer) 1 points Tangent arcs may not be created on an extended portion of the selected entity True False 8 Multiple Choice (select the best answer) 1 points In 2D mode, geometry is created at the z position selected By using the AutoCursor to select a position for the entity Parallel to the current Cplane at the current system Z depth All of the above 9 Multiple Choice (select the best answer) 1 points The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? Style Definition Attributes All of the above 10 Multiple Choice (select the best answer) 1 points Define Fillet An line tangent to two arcs An arc tangent to two entities An arc connected to two entities All of the above 11 Multiple Choice (select the best answer) 1 points After using the Xform function, what are the red entities called? Result Group Done None of the above 12 True/False (select one answer) 1 points General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. True False 13 Multiple Choice (select the best answer) 1 points What are the different Chamfering styles? Distance 1, Distance 2, and Angle. Distance, and/or Angle Distance 1, Distance 2, Width, and Angle Width and Angle 14 True/False (select one answer) 1 points To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. True False 15 Multiple Choice (select the best answer) Which one of the following Trim modes is not mutually exclusive? Trim to point 1 points Divide Default Length 16 Multiple Choice (select the best answer) 1 points In a Top view and plane, which axis is vertical parallel to? X axis Y axis Z axis All of the above 17 Multiple Choice (select the best answer) 1 points In the Translate Rotate function, the angle is calculated Relative to the horizontal axis At 3:00 in the Top view At 3:00 in the current construction plane All of the above 18 Multiple Choice (select the best answer) 1 points Which of the following entities can define a Construction plane 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc with center point, a 2D spline 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc, a flat surface, 3 points 1: multiple choice Where do full arcs start and end? correct answer. 2: multiple choice Press F9 to: correct answer. 3: true/false Arcs may not be created on an extended portion of the selected entity. correct answer. 4: multiple choice In 3D mode, geometry is created correct answer. 5: multiple choice In a top View and Plane, which axis is horizontal? correct answer. 6: true/false All basic geometry can be created through the Sketcher toolbar correct answer. 7: true/false Tangent arcs may not be created on an extended portion of the selected entity correct answer. 8: multiple choice In 2D mode, geometry is created Incorrect answer. 9: multiple choice The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? correct answer. 10: multiple choice Define Fillet correct answer. 11: multiple choice After using the Xform function, what are the red entities called? correct answer. 12: true/false General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. correct answer. 13: multiple choice What are the different Chamfering styles? correct answer. 14: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. correct answer. 15: multiple choice Which one of the following Trim modes is not mutually exclusive? correct answer. 16: multiple choice In a Top view and plane, which axis is vertical parallel to? Incorrect answer. 17: multiple choice In the Translate Rotate function, the angle is calculated Incorrect answer. 18: multiple choice Which of the following entities can define a Construction plane correct answer. Total Score: 1 Multiple Choice (select the best answer) 15 / 18 1 points Tool definition contains what information? The shape and dimensions of the tool, including how it is mounted in the turret or spindle Default values for feeds/speeds/coolant Default cutting parameters All of the above 2 True/False (select one answer) 1 points It is necessary to select geometry to face a part? True False 3 Multiple Choice (select the best answer) The safest way to change a tool number is? Update the tools parameters Change the number is the toolpath parameters Update the tool and save it in the default tool library Update the tool parameter and save it to a custom library 1 points 4 True/False (select one answer) 1 points In the toolpath Lathe Quick Groove both radius and chamfer can used on all 90 deg corners. True False 5 Multiple Choice (select the best answer) 1 points Custom tool libraries store: Feed rate and Tool offset numbers Insert names Insert, Holder and clearance information All of the above 6 Multiple Choice (select the best answer) 1 points Why is it recommended to accurately define a chuck in Mastercam? Simulation It is not recommended Collision avoidance Simulation and collision avoidance 7 Multiple Choice (select the best answer) 1 points Lead in Lead out supports? Extend/shorten, Line Extend/shorten, Vector/angle, arc Extend/shorten, Vector/angle Extend/shorten, Vector/angle, Line, Arc 8 Multiple Choice (select the best answer) 1 points What information does the top window contain in the Lathe Tool Manager? The tools active in the default tool library The tools active in the part group Lathe Tool default information The shape and dimensions of the tool, including how it is mounted in the turret or spindle. 9 True/False (select one answer) In plunge cut parameters you can plunge using tool 1 points width and angle? True False 10 Multiple Choice (select the best answer) 1 points The Lathe finish toolpath supports? OD OD, ID OD, ID, Face OD, ID, Face, Back Face 11 Multiple Choice (select the best answer) 1 points Select the compensation types? Computer/Control Wear/Reverse Wear Off All of the above 12 Multiple Choice (select the best answer) 1 points In lathe, how is the tool tip compensated? Insert radius Insert lead angle Insert trailing angle All of the above 1: multiple choice Tool definition contains what information? correct answer. 2: true/false It is necessary to select geometry to face a part? correct answer. 3: multiple choice The safest way to change a tool number is? correct answer. 4: true/false In the toolpath Lathe Quick Groove both radius and chamfer can used on all 90 deg corners. correct answer. 5: multiple choice Custom tool libraries store: correct answer. 6: multiple choice Why is it recommended to accurately define a chuck in Mastercam? correct answer. 7: multiple choice Lead in Lead out supports? correct answer. 8: multiple choice What information does the top window contain in the Lathe Tool Manager? correct answer. 9: true/false In plunge cut parameters you can plunge using tool correct answer. width and angle? 10: multiple choice The Lathe finish toolpath supports? correct answer. 11: multiple choice Select the compensation types? correct answer. 12: multiple choice In lathe, how is the tool tip compensated? correct answer 1 Multiple Choice (select the best answer) 1 points Define Fillet An line tangent to two arcs An arc tangent to two entities An arc connected to two entities All of the above 2 Multiple Choice (select the best answer) 1 points In the Xform Rotate function, the angle is calculated Relative to the horizontal axis At 3:00 in the Top view At 3:00 in the current construction plane All of the above 3 Multiple Choice (select the best answer) 1 points Which one of the following Trim function buttons is not mutually exclusive? Trim to point Divide Default Length 4 Multiple Choice (select the best answer) 1 points What are the different Wireframe Chamfering styles? Distance 1, Distance 2, and Angle. Distance, and/or Angle Distance 1, Distance 2, Width, and Angle Width and Angle 5 Multiple Choice (select the best answer) 1 points In 3D mode, geometry is created At various Z depths, unconstrained by the current system Z depth and Cplane setting By using AutoCursor to select a position or otherwise specify the X, Y, and Z values for the entity By placing the first sketched point at the default Z depth At all of the geometry positions listed above 6 True/False (select one answer) 1 points To create a parallel line that is tangent to an arc, you click the Tangent button in the line parallel ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. True False 7 Multiple Choice (select the best answer) 1 points After using the Xform function, what are the red entities called? Result Group Done None of the above 8 True/False (select one answer) 1 points All basic geometry can be created through the Sketcher toolbar True False 9 True/False (select one answer) Tangent arcs may not be created on an extended portion of the selected entity 1 points True False 10 Multiple Choice (select the best answer) 1 points Press F9 to: Show coordinate axes Show/hide the coordinate axes and system origin Show/hide Coordinate information Show/hide Zero 11 Multiple Choice (select the best answer) 1 points In a Top view and plane, which axis is vertical parallel to? X axis Y axis Z axis All of the above 12 Multiple Choice (select the best answer) 1 points Which of the following entities can define a Construction plane 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc with center point, a 2D spline 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc, a flat surface, 3 points 13 Multiple Choice (select the best answer) 1 points In 2D mode, geometry is created at the z position selected By using the AutoCursor to select a position for the entity Parallel to the current Cplane at the current system Z depth All of the above 14 True/False (select one answer) Arcs may not be created on an extended portion of the selected entity. True 1 points False 15 Multiple Choice (select the best answer) 1 points Where do full arcs start and end? 12:00 3:00 6:00 9:00 16 True/False (select one answer) 1 points General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. True False 17 Multiple Choice (select the best answer) 1 points Which is not a typical task of the View Manager? Selecting which views to use for the Cplane, Tplane, or the work coordinate system Editing the origin of a view Changing the Gview All of the above 18 Multiple Choice (select the best answer) 1 points In a top View and Plane, which axis is horizontal? X axis Y axis Z axis All 19 Multiple Choice (select the best answer) Setting a new active WCS, Cplane, and Tplane in the View Manager. Rotates the part with the CNC Rotary axis Maps the axis to the desired plane as if rotating a part by hand Changes the current view of the part Sets axis combinations using geometry 1 points 20 Multiple Choice (select the best answer) 1 points The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? Style Definition Attributes All of the above 1: multiple choice Define Fillet correct answer. • An arc tangent to two entities 2: multiple choice In the Xform Rotate function, the angle is calculated correct answer. • At 3:00 in the current construction plane 3: multiple choice Which one of the following Trim function buttons is not mutually exclusive? correct answer. • Default 4: multiple choice What are the different Wireframe Chamfering styles? correct answer. • Distance 1, Distance 2, Width, and Angle 5: multiple choice In 3D mode, geometry is created correct answer. • At all of the geometry positions listed above 6: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line parallel ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. correct answer. • True 7: multiple choice After using the Xform function, what are the red entities called? correct answer. • Group 8: true/false All basic geometry can be created through the Sketcher toolbar correct answer. • True 9: true/false Tangent arcs may not be created on an extended portion of the selected entity correct answer. • False 10: multiple choice Press F9 to: correct answer. • Show/hide the coordinate axes and system origin 11: multiple choice In a Top view and plane, which axis is vertical parallel to? correct answer. • Y axis 12: multiple choice Which of the following entities can define a Construction plane correct answer. • 2 lines, an arc, a flat surface, 3 points 13: multiple choice In 2D mode, geometry is created correct answer. • Parallel to the current Cplane at the current system Z depth 14: true/false Arcs may not be created on an extended portion of the selected entity. correct answer. • False 15: multiple choice Where do full arcs start and end? correct answer. • 3:00 16: true/false General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. correct answer. • True 17: multiple choice Which is not a typical task of the View Manager? correct answer. • Changing the Gview 18: multiple choice In a top View and Plane, which axis is horizontal? correct answer. • X axis 19: multiple choice Setting a new active WCS, Cplane, and Tplane in the View Manager. correct answer. • Maps the axis to the desired plane as if rotating a part by hand 20: multiple choice The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? correct answer. • Attributes Total Score: 20 / 20 1 Multiple Choice (select the best answer) 1 points What are the steps to optimize existing drill point locations? Select points in the correct order Select the Drill Point Manager, select Sort options, select Sort method Select the Drill Point Manager, right-click, select Sort options, select Sort method, click OK Select the operation, right-click, select Sort options, click OK 2 Multiple Choice (select the best answer) 1 points Which of these is not a toolpath compensation type? Wear Computer Radial Control 3 Multiple Choice (select the best answer) If a contour toolpath is on the wrong side of the centerline, which of the following does not correct the problem? Changing the compensation type to wear Changing the compensation direction Using the Chain Manager to reverse chain direction Re-chaining the geometry, selecting the first 1 points element as before but at the opposite end from wher 4 True/False (select one answer) 1 points Chaining a circle CCW with the cutter comp set to left will cut the outside of the circle. True False 5 Multiple Choice (select the best answer) 1 points When you highlight a new plane and select the “=” button in the , you are: Orientating the part, using machine axis Orientating the part, not using the machine axis Setting zero None of the above 6 True/False (select one answer) 1 points Chaining a rectangle CW with the cutter comp set to left will cut the inside of the rectangle. True False 7 Multiple Choice (select the best answer) 1 points Which of these is not a standard WCS selection? Geometry Normal Isometric None of the above 8 Multiple Choice (select the best answer) 1 points Toolpath verification is very important in NC programming for which of the following reason? Reduce costs Simulate graphically the machining of the part programs Detect potential errors in the part programs before they are used in try out run All of the above 9 Multiple Choice (select the best answer) When you chain geometry for a pocket with islands, the 1 points correct chaining method is which of the following? Select island tops and pocket top Select island bottom and pocket bottom Select island bottom and pocket top Select pocket bottom and island top 10 Multiple Choice (select the best answer) 1 points How do you change the name of the G-code file in Mastercam? Right-click the Operations Manager, Edit selected operations, Change NC file name, enter new name Select the desired operations, right-click, select Edit selected operations, click Change NC file Select the desired operations, right-click, click Change NC file name, enter new name Right-click the Operations Manager, Change NC file name, enter new name 11 Multiple Choice (select the best answer) 1 points Which one of the following stop options is found in the verify function? Stop on collision Stop on tool changes Stop after each operation All of the above 12 Multiple Choice (select the best answer) 1 points When you want to make multiple passes in the X and Y axes around a part, getting progressively closer with each pass, which settings do you use? Lead In/Out, tangent length set to 200% Change Contour Type to Ramp, no Lead In/Out Depth Cuts and Break Thru with finish cuts and subprogram Multi Passes with # of roughing pass, and amount 13 Multiple Choice (select the best answer) Which of these roughing options moves the tool in a linear motion according to the roughing angle? Zig Zag High Speed 1 points Morph All the above 14 Multiple Choice (select the best answer) 1 points To produce a chamfer contour, you must: Enter depth of chamfer and angle of tool Chain the outside of the contour, enter chamfer width and tip offset Chain the inside geometry of chamfer, ignore the depth Chain the bottom of the geometry of the chamfer, ignore the tool diameter 15 Multiple Choice (select the best answer) 1 points How does Mastercam control roughing profile cuts? Percentage of the tool or distance Spacing Tolerance setting All of the above 16 Multiple Choice (select the best answer) 1 points What are the two types of contours? Round and square Open and closed Outside and inside None of the above 17 Multiple Choice (select the best answer) 1 points When you chain a contour and it does not chain completely around the part, which of the following is not the possible cause? A gap or break in the geometry path Duplicate geometry entities A reversed normal Seemingly connected geometry that includes entities at varying Z depths 18 Multiple Choice (select the best answer) When verifying a pocket island machining toolpath, you notice that some material has been left. To correct this you should first try: 1 points Decreasing the stepover amount for the tool Changing the size of the tool to a much smaller tool Selecting a different type of toolpath Changing material size 19 Multiple Choice (select the best answer) 1 points Name all of the contour toolpath types: Remachining, 2D, 2D chamfer, Oscillate, 3D, 3D Chamfer, or Ramp Remachining, Oscillate, 2D, 3D, Chamfer, Slot Mill and Ramp Remachining, Counterbore, 2D,3D, and Ramp Remachining, Chamfer, 2D,3D, Counterbore, and Ramp 20 Multiple Choice (select the best answer) 1 points To create a setup sheet for toolpath operations, you select the operations and: Left-mouse click, select Setup sheet Right-mouse click, select Setup sheet Middle-mouse click, select Setup sheet Write the process using Notepad 1: multiple choice What are the steps to optimize existing drill point locations? correct answer. • Select the Drill Point Manager, right-click, select Sort options, select Sort method, click OK 2: multiple choice Which of these is not a toolpath compensation type? correct answer. • Radial 3: multiple choice If a contour toolpath is on the wrong side of the centerline, which of the following does not correct the problem? correct answer. • Changing the compensation type to wear 4: true/false Chaining a circle CCW with the cutter comp set to left will cut the outside of the circle. correct answer. • False 5: multiple choice When you highlight a new plane and select the “=” button in the , you are: correct answer. • Orientating the part, not using the machine axis 6: true/false Chaining a rectangle CW with the cutter comp set to left will cut the inside of the rectangle. correct answer. • False 7: multiple choice Which of these is not a standard WCS selection? correct answer. • None of the above 8: multiple choice Toolpath verification is very important in NC programming for which of the following reason? correct answer. • All of the above 9: multiple choice When you chain geometry for a pocket with islands, the correct chaining method is which of the following? correct answer. • Select pocket bottom and island top 10: multiple choice How do you change the name of the G-code file in Mastercam? correct answer. • Select the desired operations, right-click, select Edit selected operations, click Change NC file 11: multiple choice Which one of the following stop options is found in the verify function? correct answer. • All of the above 12: multiple choice When you want to make multiple passes in the X and Y axes around a part, getting progressively closer with each pass, which settings do you use? correct answer. • Multi Passes with # of roughing pass, and amount 13: multiple choice Which of these roughing options moves the tool in a linear motion according to the roughing angle? correct answer. • Zig Zag 14: multiple choice To produce a chamfer contour, you must: correct answer. • Chain the outside of the contour, enter chamfer width and tip offset 15: multiple choice How does Mastercam control roughing profile cuts? correct answer. • Percentage of the tool or distance 16: multiple choice What are the two types of contours? correct answer. • Open and closed 17: multiple choice When you chain a contour and it does not chain completely around the part, which of the following is not the possible cause? correct answer. • A reversed normal 18: multiple choice When verifying a pocket island machining toolpath, you notice that some material has been left. To correct this you should first try: correct answer. • Decreasing the stepover amount for the tool 19: multiple choice Name all of the contour toolpath types: correct answer. • Remachining, 2D, 2D chamfer, Oscillate, 3D, 3D Chamfer, or Ramp 20: multiple choice To create a setup sheet for toolpath operations, you select the operations and: correct answer. Total Score: 1 True/False (select one answer) 20 / 20 1 points You can set the helical entry position to a specific point. True False 2 Multiple Choice (select the best answer) How do you activate thin wall cutting in a dynamic milling toolpath? Select Optimize cut order within pocket in the Cut Parameters page. Activate Depths cuts and select the Tapered walls check box. Then define the angle. You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (remachining). You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (finishing). 1 points • Right-mouse click, select Setup sheet 3 Multiple Choice (select the best answer) 1 points What are the chaining requirements for a 2D High Speed Core mill toolpath? One closed chain that defines the stock boundary. Two closed chains, the outermost chain defines the stock boundary and the innermost defines the toolpath boundary. Supports any number of closed and open chains. The outermost chain defines the stock boundary; Mastercam closes open chains with a straight line. None of the above 4 Multiple Choice (select the best answer) 1 points Mastercam applies the Additional slot width distance you define in the Entry Motion page for a Custom entry method by: Setting the entire entry slot width equal to the specified distance. Adding half of the specified distance to each side of the tool diameter to define the total entry slot width. Adding the entire specified distance to each side of tool diameter to define the total entry slot width. All of the above 5 True/False (select one answer) 1 points 2D high speed Area mill toolpaths require one or more chains. Chains can be open or closed. True False 6 True/False (select one answer) 1 points Mastercam always sets the Depth value to zero (0.0) in the Linking Parameters page. True False 7 True/False (select one answer) 1 points When configuring the 2D High Speed Rest mill toolpath, you select one or more operations to rest mill from the list of the toolpaths in the active machine group. True False 8 True/False (select one answer) 1 points Changing entry methods for dynamic mill toolpath doesn’t affect the tool motion all that much. True/False True False 9 Multiple Choice (select the best answer) 1 points Which Peel mill toolpath parameter do you change to ease the tool gradually into the material, rather than engaging it fully on the first cut? Entry settings on the Lead In/Out page. Feed plane on the Linking Parameters page. Extend entry on the Cut Parameters page. None of the above. 10 Multiple Choice (select the best answer) 1 points For thin wall milling, a best practice is to set your stepover to: Anything you choose. Less than 75% of the cutter diameter to avoid pulling the tool out of the tool holder. Greater than 75% of the cutter diameter to maintain a smooth cutting motion. None of the above. 11 True/False (select one answer) 1 points 2D High Speed Blend mill toolpaths smoothly transition cut passes between two dissimilar open contours True False 12 Multiple Choice (select the best answer) 1 points When using the Profile entry method for dynamic milling toolpaths, Mastercam calculates the entry point based on: The point position selected when chaining the toolpath geometry. Smallest area to machine. Largest area to machine. None of the above. 13 True/False (select one answer) Activating Microlift on back moves (Cut Parameters) helps evacuate chips more cleanly and reduce tool 1 points temperature during Peel mill cut passes. True False 14 True/False (select one answer) 1 points When multiple chains are selected for the toolpath, Mastercam assigns the chain with the smallest area as the material to be machined and uses the largest chain for tool containment. True False 15 True/False (select one answer) 1 points 2D high speed Area mill toolpaths support only a helical entry method. True False 16 True/False (select one answer) 1 points The Machine finish passes only at final depths check box must be selected before you can access the Thin wall settings. True False 17 Multiple Choice (select the best answer) 1 points What is the best practice for offsetting the tool from the selected contours when configuring a 2D High Speed Blend mill toolpath? Can’t be done. Set the Cutter compensation in the toolpath’s Cut parameters page. Use Xform, Offset to create new drive geometry. Then chain the offset geometry. None of the above. 18 Multiple Choice (select the best answer) How can you eliminate sharp corners in the Core mill toolpath? Modify the selected drive geometry. Select Smoothing in the Cut Parameters page. Activate the Trochoidal Motion page and define its 1 points parameters. Select Output 3D arc moves in the Transitions page. 19 Multiple Choice (select the best answer) 1 points Which setting(s) controls the number of entry moves in the toolpath? Entry method and Entry feed rate (Transitions page) XY Stepover (Cut Parameters page). Keep tool down within Distance/% of tool diameter (Cut Parameters page). All of the above 20 True/False (select one answer) 2D High Speed Peel mill toolpaths require two open chains. True False 1 points 1: true/false You can set the helical entry position to a specific point. correct answer. • True 2: multiple choice How do you activate thin wall cutting in a dynamic milling toolpath? correct answer. • You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (finishing). 3: multiple choice What are the chaining requirements for a 2D High Speed Core mill toolpath? correct answer. • Two closed chains, the outermost chain defines the stock boundary and the innermost defines the toolpath boundary. 4: multiple choice Mastercam applies the Additional slot width distance you define in the Entry Motion page for a Custom entry method by: Incorrect answer. • Adding the entire specified distance to each side of tool diameter to define the total entry slot width. 5: true/false 2D high speed Area mill toolpaths require one or more chains. Chains can be open or closed. correct answer. • True 6: true/false Mastercam always sets the Depth value to zero (0.0) in the Linking Parameters page. correct answer. • False 7: true/false When configuring the 2D High Speed Rest mill toolpath, you select one or more operations to rest mill from the list of the toolpaths in the active machine group. Incorrect answer. • True 8: true/false Changing entry methods for dynamic mill toolpath doesn’t affect the tool motion all that much. True/False correct answer. • False 9: multiple choice Which Peel mill toolpath parameter do you change to ease the tool gradually into the material, rather than engaging it fully on the first cut? correct answer. • Extend entry on the Cut Parameters page. 10: multiple choice For thin wall milling, a best practice is to set your stepover to: correct answer. • Less than 75% of the cutter diameter to avoid pulling the tool out of the tool holder. 11: true/false 2D High Speed Blend mill toolpaths smoothly transition cut passes between two dissimilar open contours correct answer. • True 12: multiple choice When using the Profile entry method for dynamic milling toolpaths, Mastercam calculates the entry point based on: correct answer. • Largest area to machine. 13: true/false Activating Microlift on back moves (Cut Parameters) helps evacuate chips more cleanly and reduce tool temperature during Peel mill cut passes. correct answer. • True 14: true/false When multiple chains are selected for the toolpath, Mastercam assigns the chain with the smallest area as correct answer. • False the material to be machined and uses the largest chain for tool containment. 15: true/false 2D high speed Area mill toolpaths support only a helical entry method. correct answer. • False 16: true/false The Machine finish passes only at final depths check box must be selected before you can access the Thin wall settings. correct answer. • False 17: multiple choice What is the best practice for offsetting the tool from the selected contours when configuring a 2D High Speed Blend mill toolpath? correct answer. • Use Xform, Offset to create new drive geometry. Then chain the offset geometry. 18: multiple choice How can you eliminate sharp corners in the Core mill toolpath? correct answer. • Select Smoothing in the Cut Parameters page. 19: multiple choice Which setting(s) controls the number of entry moves in the toolpath? correct answer. • Entry method and Entry feed rate (Transitions page) 20: true/false 2D High Speed Peel mill toolpaths require two open chains. correct answer. • False Total Score: 18 / 20 Lathe 1 Multiple Choice (select the best answer) 1 points Which one of the following Trim modes is not mutually exclusive? Trim to point Divide Default Length 2 True/False (select one answer) Tangent arcs may not be created on an extended 1 points portion of the selected entity True False 3 Multiple Choice (select the best answer) 1 points What are the different Chamfering styles? Distance 1, Distance 2, and Angle. Distance, and/or Angle Distance 1, Distance 2, Width, and Angle Width and Angle 4 Multiple Choice (select the best answer) 1 points In a top View and Plane, which axis is horizontal? X axis Y axis Z axis All 5 Multiple Choice (select the best answer) 1 points Define Fillet An line tangent to two arcs An arc tangent to two entities An arc connected to two entities All of the above 6 True/False (select one answer) 1 points Arcs may not be created on an extended portion of the selected entity. True False 7 Multiple Choice (select the best answer) Press F9 to: Show/hide coordinate axes Show/hide the coordinate axes and system origin Show/hide Coordinate information Show/hide Zero 1 points 8 Multiple Choice (select the best answer) 1 points After using the Xform function, what are the red entities called? Result Group Done None of the above 9 Multiple Choice (select the best answer) 1 points The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? Style Definition Attributes All of the above 10 Multiple Choice (select the best answer) 1 points In the Translate Rotate function, the angle is calculated Relative to the horizontal axis At 3:00 in the Top view At 3:00 in the current construction plane All of the above 11 Multiple Choice (select the best answer) 1 points In a Top view and plane, which axis is vertical parallel to? X axis Y axis Z axis All of the above 12 Multiple Choice (select the best answer) In 2D mode, geometry is created at the z position selected By using the AutoCursor to select a position for the entity Parallel to the current Cplane at the current system Z depth All of the above 1 points 13 Multiple Choice (select the best answer) 1 points In 3D mode, geometry is created At various Z depths, unconstrained by the current system Z depth and Cplane setting By using AutoCursor to select a position or otherwise specify the X, Y, and Z values for the entity By placing the first sketched point at the default Z depth At all of the geometry positions listed above 14 True/False (select one answer) 1 points To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. True False 15 Multiple Choice (select the best answer) 1 points Where do full arcs start and end? 12:00 3:00 6:00 9:00 16 True/False (select one answer) 1 points General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. True False 17 Multiple Choice (select the best answer) 1 points Which of the following entities can define a Construction plane 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc with center point, a 2D spline 2 lines, an arc, 2 points, a 3D spline 2 lines, an arc, a flat surface, 3 points 18 True/False (select one answer) All basic geometry can be created through the Sketcher 1 points toolbar True False 1: multiple choice Which one of the following Trim modes is not mutually exclusive? correct answer. • Default 2: true/false Tangent arcs may not be created on an extended portion of the selected entity correct answer. • False 3: multiple choice What are the different Chamfering styles? correct answer. • Distance 1, Distance 2, Width, and Angle 4: multiple choice In a top View and Plane, which axis is horizontal? correct answer. • X axis 5: multiple choice Define Fillet correct answer. • An arc tangent to two entities 6: true/false Arcs may not be created on an extended portion of the selected entity. correct answer. • False 7: multiple choice Press F9 to: correct answer. • Show/hide the coordinate axes and system origin 8: multiple choice After using the Xform function, what are the red entities called? correct answer. • Group 9: multiple choice The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? correct answer. • Attributes 10: multiple choice In the Translate Rotate function, the angle is calculated correct answer. • At 3:00 in the current construction plane 11: multiple choice In a Top view and plane, which axis is vertical parallel to? correct answer. • Y axis 12: multiple choice In 2D mode, geometry is created correct answer. • Parallel to the current Cplane at the current system Z depth 13: multiple choice In 3D mode, geometry is created correct answer. • At all of the geometry positions listed above 14: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you correct answer. • True want the parallel line to be tangent to. 15: multiple choice Where do full arcs start and end? correct answer. • 3:00 16: true/false General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. correct answer. • True 17: multiple choice Which of the following entities can define a Construction plane correct answer. • 2 lines, an arc, a flat surface, 3 points 18: true/false All basic geometry can be created through the Sketcher toolbar correct answer. • True Total Score: 18 / 18 Lathe Toolpaths 1 Multiple Choice (select the best answer) 1 points What information does the top window contain in the Lathe Tool Manager? The tools active in the default tool library The tools active in the part group Lathe Tool default information The shape and dimensions of the tool, including how it is mounted in the turret or spindle. 2 True/False (select one answer) 1 points In the toolpath Lathe Quick Groove both radius and chamfer can used on all 90 deg corners. True False 3 Multiple Choice (select the best answer) 1 points Tool definition contains what information? The shape and dimensions of the tool, including how it is mounted in the turret or spindle Default values for feeds/speeds/coolant Default cutting parameters All of the above 4 Multiple Choice (select the best answer) 1 points In lathe, how is the tool tip compensated? Insert radius Insert lead angle Insert trailing angle All of the above 5 True/False (select one answer) 1 points In plunge cut parameters you can plunge using tool width and angle? True False 6 True/False (select one answer) It is necessary to select geometry to face a part? 1 points True False 7 Multiple Choice (select the best answer) 1 points Lead in Lead out supports? Extend/shorten, Line Extend/shorten, Vector/angle, arc Extend/shorten, Vector/angle Extend/shorten, Vector/angle, Line, Arc 8 Multiple Choice (select the best answer) 1 points Select the compensation types? Computer/Control Wear/Reverse Wear Off All of the above 9 Multiple Choice (select the best answer) 1 points Why is it recommended to accurately define a chuck in Mastercam? Simulation It is not recommended Collision avoidance Simulation and collision avoidance 10 Multiple Choice (select the best answer) 1 points The safest way to change a tool number is? Update the tools parameters Change the number is the toolpath parameters Update the tool and save it in the default tool library Update the tool parameter and save it to a custom library 11 Multiple Choice (select the best answer) Custom tool libraries store: Feed rate and Tool offset numbers Insert names Insert, Holder and clearance information 1 points All of the above 12 Multiple Choice (select the best answer) 1 points The Lathe finish toolpath supports? OD OD, ID OD, ID, Face OD, ID, Face, Back Face 1: multiple choice What information does the top window contain in the Lathe Tool Manager? Incorrect answer. • The tools active in the part group 2: true/false In the toolpath Lathe Quick Groove both radius and chamfer can used on all 90 deg corners. correct answer. • True 3: multiple choice Tool definition contains what information? correct answer. • All of the above 4: multiple choice In lathe, how is the tool tip compensated? correct answer. • All of the above 5: true/false In plunge cut parameters you can plunge using tool width and angle? correct answer. • False 6: true/false It is necessary to select geometry to face a part? correct answer. • False 7: multiple choice Lead in Lead out supports? correct answer. • Extend/shorten, Vector/angle, Line, Arc 8: multiple choice Select the compensation types? correct answer. • All of the above 9: multiple choice Why is it recommended to accurately define a chuck in Mastercam? correct answer. • Simulation and collision avoidance 10: multiple choice The safest way to change a tool number is? correct answer. • Update the tool parameter and save it to a custom library 11: multiple choice Custom tool libraries store: correct answer. • All of the above 12: multiple choice The Lathe finish toolpath supports? correct answer. • OD, ID, Face, Back Face Total Score: 11 / 12 1: true/false Mastercam always sets the Depth value to zero (0.0) in the Linking Parameters page. correct answer. • False 2: multiple choice How do you activate thin wall cutting in a dynamic milling toolpath? correct answer. • You don’t. It’s part of Mastercam’s traditional pocket toolpath parameters (finishing). 3: multiple choice What is the best practice for offsetting the tool from the selected contours when configuring a 2D High Speed Blend mill toolpath? correct answer. • Use Xform, Offset to create new drive geometry. Then chain the offset geometry. 4: multiple choice For thin wall milling, a best practice is to set your stepover to: correct answer. • Less than 75% of the cutter diameter to avoid pulling the tool out of the tool holder. 5: multiple choice How can you eliminate sharp corners in the Core mill toolpath? correct answer. • Select Smoothing in the Cut Parameters page. 6: multiple choice When using the Profile entry method for dynamic milling toolpaths, Mastercam calculates the entry point based on: correct answer. • Largest area to machine. 7: true/false The Custom entry method requires that you first select an open chain before configuring the toolpath. Incorrect answer. • False 8: true/false 2D High Speed Blend mill toolpaths smoothly transition cut passes between two dissimilar open contours correct answer. • True 9: multiple choice When you highlight a new plane and select the “=” button in the , you are: correct answer. • Orientating the part, not using the machine axis 10: multiple choice How do you change the name of the G-code file in Mastercam? correct answer. • Select the desired operations, right-click, select Edit selected operations, click Change NC file 11: multiple choice When you want to make multiple passes in the X and Y axes around a part, getting progressively closer with each pass, which settings do you use? correct answer. • Multi Passes with # of roughing pass, and amount 12: multiple choice Which of these is not a standard WCS selection? correct answer. • None of the above 13: multiple choice When verifying a pocket island machining toolpath, you notice that some material has been left. To correct this you should first try: correct answer. • Decreasing the stepover amount for the tool 14: multiple To create a setup sheet for toolpath operations, you correct answer. • Right-mouse choice select the operations and: click, select Setup sheet 15: multiple choice To produce a chamfer contour, you must: correct answer. • Chain the outside of the contour, enter chamfer width and tip offset 16: multiple choice Which of these roughing options moves the tool in a linear motion according to the roughing angle? correct answer. • Zig Zag 17: true/false General Selection is always active when you are not using a function such as creating geometry or analyzing an entity. correct answer. • True 18: multiple choice Which one of the following Trim function buttons is not mutually exclusive? correct answer. • Default 19: multiple choice In 3D mode, geometry is created correct answer. • At all of the geometry positions listed above 20: multiple choice Which of the following entities can define a Construction plane correct answer. • 2 lines, an arc, a flat surface, 3 points 21: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line parallel ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. correct answer. • True 22: multiple choice Which is not a typical task of the View Manager? correct answer. • Changing the Gview 23: multiple choice Where do full arcs start and end? correct answer. • 3:00 24: multiple choice In a Top view and plane, which axis is vertical parallel to? correct answer. • Y axis 1 Multiple Choice (select the best answer) 1 points Define Fillet An line tangent to two arcs An arc tangent to two entities An arc connected to two entities All of the above 2 Multiple Choice (select the best answer) 1 points In 2D mode, geometry is created at the z position selected By using the AutoCursor to select a position for the entity Parallel to the current Cplane at the current system Z depth All of the above 3 Multiple Choice (select the best answer) 1 points After using the Xform function, what are the red entities called? Result Group Done None of the above 4 Multiple Choice (select the best answer) 1 points Press F9 to: Show/hide coordinate axes Show/hide the coordinate axes and system origin Show/hide Coordinate information Show/hide Zero 5 Multiple Choice (select the best answer) In 3D mode, geometry is created At various Z depths, unconstrained by the current system Z depth and Cplane setting By using AutoCursor to select a position or otherwise specify the X, Y, and Z values for the entity By placing the first sketched point at the default Z depth 1 points At all of the geometry positions listed above 6 True/False (select one answer) 1 points Arcs may not be created on an extended portion of the selected entity. True False 7 True/False (select one answer) 1 points To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. True False 8 Multiple Choice (select the best answer) 1 points In a top View and Plane, which axis is horizontal? X axis Y axis Z axis All 9 Multiple Choice (select the best answer) 1 points Where do full arcs start and end? 12:00 3:00 6:00 9:00 10 Multiple Choice (select the best answer) 1 points The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? Style Definition Attributes All of the above q5,q10,q12,q4,q6 11 True/False (select one answer) 1 points It is necessary to select geometry to face a part? True False 12 Multiple Choice (select the best answer) 1 points The safest way to change a tool number is? Update the tools parameters Change the number is the toolpath parameters Update the tool and save it in the default tool library Update the tool parameter and save it to a custom library 13 Multiple Choice (select the best answer) 1 points Custom tool libraries store: Feed rate and Tool offset numbers Insert names Insert, Holder and clearance information All of the above 14 Multiple Choice (select the best answer) 1 points In lathe, how is the tool tip compensated? Insert radius Insert lead angle Insert trailing angle All of the above 15 Multiple Choice (select the best answer) 1 points The Lathe finish toolpath supports? OD OD, ID OD, ID, Face OD, ID, Face, Back Face 16 Multiple Choice (select the best answer) What information does the top window contain in the Lathe Tool Manager? The tools active in the default tool library 1 points The tools active in the part group Lathe Tool default information The shape and dimensions of the tool, including how it is mounted in the turret or spindle. 17 Multiple Choice (select the best answer) 1 points Select the compensation types? Computer/Control Wear/Reverse Wear Off All of the above 18 Multiple Choice (select the best answer) 1 points Tool definition contains what information? The shape and dimensions of the tool, including how it is mounted in the turret or spindle Default values for feeds/speeds/coolant Default cutting parameters All of the above 19 Multiple Choice (select the best answer) 1 points Lead in Lead out supports? Extend/shorten, Line Extend/shorten, Vector/angle, arc Extend/shorten, Vector/angle Extend/shorten, Vector/angle, Line, Arc 20 True/False (select one answer) In plunge cut parameters you can plunge using tool width and angle? True False 1 points 1: multiple choice Define Fillet correct answer. • An arc tangent to two entities 2: multiple choice In 2D mode, geometry is created correct answer. • Parallel to the current Cplane at the current system Z depth 3: multiple choice After using the Xform function, what are the red entities called? correct answer. • Group 4: multiple choice Press F9 to: correct answer. • Show/hide the coordinate axes and system origin 5: multiple choice In 3D mode, geometry is created correct answer. • At all of the geometry positions listed above 6: true/false Arcs may not be created on an extended portion of the selected entity. correct answer. • False 7: true/false To create a parallel line that is tangent to an arc, you click the Tangent button in the line endpoint ribbon bar; select the reference line, and then choose the entity you want the parallel line to be tangent to. correct answer. • True 8: multiple choice In a top View and Plane, which axis is horizontal? correct answer. • X axis 9: multiple choice Where do full arcs start and end? correct answer. • 3:00 10: multiple choice The Color, Line Style, Point Style, Level, Line Width, Surface Density are an entity’s what? correct answer. • Attributes 11: true/false It is necessary to select geometry to face a part? correct answer. • False 12: multiple choice The safest way to change a tool number is? correct answer. • Update the tool parameter and save it to a custom library 13: multiple choice Custom tool libraries store: correct answer. • All of the above 14: multiple choice In lathe, how is the tool tip compensated? correct answer. • All of the above 15: multiple choice The Lathe finish toolpath supports? correct answer. • OD, ID, Face, Back Face 16: multiple choice What information does the top window contain in the Lathe Tool Manager? correct answer. • The tools active in the part group 17: multiple choice Select the compensation types? correct answer. • All of the above 18: multiple choice Tool definition contains what information? correct answer. • All of the above 19: multiple choice Lead in Lead out supports? correct answer. • Extend/shorten, Vector/angle, Line, Arc 20: true/false In plunge cut parameters you can plunge using tool width and angle? correct answer. • False Score: 20 / 20