PR-1078 - Hydrogen Sulphide Management Procedure

advertisement

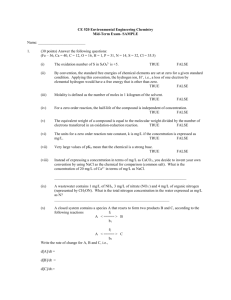

Petroleum Development Oman L.L.C. Document Title: Hydrogen Sulphide (H2S) Management Document ID Document Type Security Discipline Owner Issue Date Revision PR-1078 Procedure Unrestricted Engineering and Operations UOP – Functional Operations Manager May 2012 4.1 This document is the property of Petroleum Development Oman, LLC. Neither the whole nor any part of this document may be disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical, reprographic recording or otherwise) without prior written consent of the owner. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 This page was intentionally left blank Page 2 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC i Revision: 4.1 Effective: May-12 Document Authorisation Authorised For Issue – May 2011 Page 3 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 ii Revision History The following is a brief summary of the 4 most recent revisions to this document. Details of all revisions prior to these are held on file by the issuing department. Revision No. Date Author Scope / Remarks 4.1 May-12 Robin Norman UOP61 See Interim Amendment 1078_0512_01 4.0 Apr-11 Tom Moffat UOP95 Update, revise, reformat in conjunction with UOP, HSE, UEP 3.0 Jul-07 Robin Norman UOP6 Reformat and revision in conjunction with HSE Engineers. 2.0 Feb-01 UOP1 Minor Revision of 2.2.5 & 2.8 to incorporate user feedback comments 1.0 Sep-98 UOP1 SI-02 rewritten to new format and merged with SI-10. iii Related Business Processes Code Business Process (EPBM 4.0) EP.71 Produce Hydrocarbons EP.72 Maintain & Assure facilities Integrity iv Related Corporate Management Frame Work (CMF) Documents The related CMF Documents can be retrieved from the CMF Business Control Portal. Refer to Appendix 2 Page 4 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 TABLE OF CONTENTS i Document Authorisation ......................................................................................................... 3 ii Revision History ..................................................................................................................... 4 iii Related Business Processes ................................................................................................. 4 iv Related Corporate Management Frame Work (CMF) Documents ........................................ 4 1 Introduction ............................................................................................................................ 7 2 3 4 1.1 Background ...................................................................................................................... 7 1.2 Purpose ............................................................................................................................ 7 1.3 Key Rules regarding H2S ................................................................................................. 7 1.4 Changes to the Document ............................................................................................... 8 1.5 Step-out Approval............................................................................................................. 8 H2S Hazards, Classification and Access Control .................................................................. 9 2.1 Physiological Properties ................................................................................................... 9 2.2 Physical Properties of H2S .............................................................................................. 9 2.3 Facility Classification and Area Controls ........................................................................ 10 2.4 Area H2S Classification within a Sour Facility ................................................................ 11 2.5 Access Prerequisites ...................................................................................................... 11 2.6 Numbers Permitted to Enter (at any one instance) ........................................................ 12 2.7 Departure ....................................................................................................................... 13 2.8 Work Outside of Facility Perimeter Fences .................................................................... 13 2.9 Formal H2S Training Courses ........................................................................................ 14 H2S Safety and Emergency Response ................................................................................ 15 3.1 Activities requiring BA .................................................................................................... 15 3.2 H2S Detection ................................................................................................................ 15 3.3 Alarms and Mustering .................................................................................................... 16 3.4 Rescue ........................................................................................................................... 16 3.5 Emergency Procedures and Drills.................................................................................. 16 Safe Worksite Practices in H2S Facilities ............................................................................ 17 4.1 Job Planning, Hazard Identification and Assessment .................................................... 17 4.2 Permit to Work................................................................................................................ 18 4.3 Isolation Procedures ...................................................................................................... 18 4.4 Purging and Returning Equipment to Service ................................................................ 18 4.5 Sample Points and Safe Sampling................................................................................. 18 Appendix 1 - Abbreviations ......................................................................................................... 19 Appendix 2 – Reference Material ................................................................................................ 20 Appendix 3 - User Feedback Page ............................................................................................. 21 Interim Amendment 1078_0512_01 ............................................................................................ 22 Page 5 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Page 6 PR-1078 - Hydrogen Sulphide (H2S) Management Revision: 4.1 Effective: May-12 Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 1 Introduction 1.1 Background Revision: 4.1 Effective: May-12 Hydrogen Sulphide (H2S) is an extremely dangerous substance and can cause fatalities if not managed properly. H2S is present in more of PDO’s operations as existing fields begin to sour and as high sour developments are brought on stream. This procedure deals with the identification and assessment of the hazards and the management of the associated risk for “sour gas”, or gas containing H2S. H2S in the upstream oil and gas industry comes from: 1.2 the original reservoir, as a result of the hydrocarbon source material and the conditions under which it was converted to oil and gas. If this is the case then H2S will be produced with the fluids the reservoir after prolonged injection of water with oxygen (brackish or formation water) which may result in 'souring' of the fluids within it due to the action of sulphate reducing bacteria (SRB) introduced during the injection process. Any H2S will be subsequently produced with fluids. Purpose The purpose of this procedure is to outlines the hazards associated with H2S and the steps required to assess and manage the associated risk, and protect personnel within Production Operations. 1.3 Page 7 Key Rules regarding H2S a) Facilities are classified as either sweet, low sour, high sour or critical sour (refer to Section 2 - Classification). Unless facilities are classified as sweet, H2S management procedures shall be followed at all times. Additional rules apply to high or critical sour facilities. b) When dealing with sour gas, the primary focus should be on the controls that prevent release or exposure, and a secondary but also important focus should be on the recovery measures. These are illustrated in the bow-tie diagram below: PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 1.4 Revision: 4.1 Effective: May-12 c) Strict access control requirements are mandated for sour facilities d) Personnel shall have specific training to work in or visit sour facilities e) Breathing apparatus shall be worn for specific activities f) Emergency response plans are established for all facilities, and sour facilities shall have Emergency Response Procedures (ERP’s) which specifically address the sour aspects of the operation. Drills shall be conducted regularly to keep personnel trained on the ERP’s. g) A combination of fixed and portable H2S detection systems shall be used to provide warning of the presence of H2S in the atmosphere. h) Risk assessments shall be done for sour activities, and the job procedures, hazards and controls shall be identified to ensure the work is done safely i) Sour equipment shall be properly isolated, gas freed and made safe prior to breaking of containment. When returning to service, proper assembly, tightening, purging and leak testing shall be carried out to ensure integrity. j) Sampling of sour fluids will be strictly controlled and managed, using engineered sample points, breathing apparatus and the buddy system. Changes to the Document Responsibility for the upkeep of the Document shall be with Functional Operations Manager UOP, the Owner. Changes to this document shall only be authorised and approved by the Owner. Users of the Document who identify inaccuracy or ambiguity can notify the Custodian or his/her delegate and request changes be initiated. The Document Owner and the Document Custodian should ensure review and reverification of this procedure every 3 years. 1.5 Step-out Approval This procedure is mandatory and shall be complied with at all times. Should compliance with the procedure be considered inappropriate or the intended activity cannot be effectively completed or safely performed, then step out authorisation and approval shall be obtained in accordance with PR-1001e – Operations Procedure Temporary Variance, prior to any changes or activities associated with the procedure being carried out. Page 8 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 2 H2S Hazards, Classification and Access Control 2.1 Physiological Properties Revision: 4.1 Effective: May-12 H2S has acute effects on people, as follows: Level of Concern H2S concentration in air Unpleasant Odour 0.13 ppm 8 Hour Threshold Limit Value (TLV) 5 ppm Immediately Dangerous to Life and Health (IDLH) 100 ppm Onset of significant health effects 300 ppm Immediate unconsciousness, onset of worker fatalities 650 ppm NOTE: 1% H2S equates to 10,000 ppm 2.2 Physical Properties of H2S H2S is extremely toxic and can cause death at very low concentrations H2S, also known as sour gas, is a colourless toxic, corrosive and flammable gas, which is heavier than air and tends to collect in low-lying areas such as trenches, sumps and confined spaces. H2S reacts with the internal surfaces of carbon steel vessels in the absence of oxygen to form pyrophoric iron sulphide. Pyrophoric iron sulphide can autoignite when exposed to air. Property Characteristic Colour Colourless Odour H2S concentration, when: <100 ppm - has a distinctive, offensive smell – similar to rotten eggs >100 ppm - impairs the sense of smell; therefore, the nose cannot be relied upon to detect the presence of H2S Vapour Density 1.189 – heavier than air Explosive limits and flammability 4.3 to 46 percent – by volume in air H2S explodes over a very wide range, when: mixed in the right proportions with air (oxygen), and there is a source of ignition. Burns readily (with a distinctive blue flame) Produces Sulphur Dioxide (SO2) – another toxic gas Page 9 Auto Ignition Temperature 260ºC Reactivity Can react with carbon steel, in the absence of oxygen – forming Pyrophoric Iron Sulphide (on the internal surfaces of vessels), which in turn can react upon contact with air (oxygen) – auto igniting PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision: 4.1 Effective: May-12 Petroleum Development Oman LLC Water Solubility H2S is: Readily dissolved in both water and hydrocarbons Dependent on temperature and pressure to be soluble Quickly released, by simply agitating the fluid Corrosives H2S forms a corrosive mixture with water Boiling Point 60ºC at normal pressure Liquefied H2S boils at a very low temperature and is normally found as a gas 2.3 Facility Classification and Area Controls Facilities in PDO are classified as follows: 1. Sweet 2. Low Risk Sour 3. High Risk Sour 4. Critical Sour (currently only applies to Harweel 2AB, Birba and Al Noor facilities) Each facility in PDO is classified according to criteria set out in SP-1190 - Design For Sour Service Specification. Operations staff at each facility shall understand the classification of their facility and the appropriate level of controls that apply: Facility Classification Sweet No additional requirement to base standards Low Risk Sour Company/Contractor personnel shall be made aware of the hazard and the appropriate actions to escape or shelter from a credible release of the hazard. Competencies in H2S, breathing apparatus, and sour work practices High Risk Sour And Critical Sour Page 10 Basic Requirements As stated above plus: Company/Contractor personnel shall be provided with suitable equipment and knowledge to selfescape to a place of safety in case of a credible release. Work (or rest) that could reasonably be completed further from the hazard source shall not take place. Activities requiring large maintenance or construction work forces shall be subject to Quantitative Risk Assessment and Bow-Tie assessment. A SIMOPs plan should be in force for simultaneous operations under different lines of command. Emergency Planning Zone (based on toxic risk) and Emergency Response Plans to be established PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision: 4.1 Effective: May-12 Petroleum Development Oman LLC 2.4 Area H2S Classification within a Sour Facility Within a sour facility, some facilities are zoned on the level of toxic gas risk present in accordance with SP-1190 - Design For Sour Service Specification. This is typically determined by quantitative risk assessment considering the partial pressure of H 2S in the process units, the layout/spacing of the unit, and the nature of the work activities there. Sour facilities shall have the zones identified in consultation with Corporate MSE and marked by Operations, and personnel shall be trained accordingly. Rules which apply to the zones are as follows: Zone Description Controls Green Low toxic H2S gas hazard No additional controls Yellow A credible release of H2S could result in a concentration in air above IDLH levels in the vicinity of the process units or in the vicinity of the well. As High Risk Sour Facility Classification plus: H2S is expected to be present in the breathing zone for an area (confined space, ground level or elevated working platform) as part of normal operations at a concentration in air above the 8 hour TLV. As Yellow Zone plus: Red OR A credible release of H2S could result in a concentration in air above 650 ppm in the process units or in the vicinity of the well. The number of persons present shall be actively minimised (reference Section 2.6) Area / activity specific sour operating procedures including wearing Respiratory Protective Equipment at all times. Specific area access control. AND The perceived operational risk is higher than in normal operations e.g. operational risk may be perceived to be higher during start up or during periods when a facility is operating with uncertain static integrity, and therefore Red Zone operating rules may be enforced. 2.5 Access Prerequisites Access to H2S designated areas shall only be allowed provided the following have been adhered to: Page 11 Area Authority or Approved Gas Tester has completed a gas test of the area at the start of the shift and after scheduled breaks, and the recorded results indicate < 5 ppm of H2S in air. Valid Permit to Work has been issued, authorised by the Responsible Supervisor, validated by the Area Authority and specifying clearly the reasons for entry. Valid H2S Entry Permits are held by all persons entering the sour classified facility and that they have been hung on the numbered slot board in the Control Room. Persons entering the restricted area have the correct safety equipment for that area which shall include personal H2S monitors. PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision: 4.1 Effective: May-12 Petroleum Development Oman LLC All persons entering the restricted area are fully conversant with the ‘Buddy’ system and are aware of the escape routes and Area Muster Points. All persons entering the restricted area have completed and signed the Station Entry logbook i.e. Name, Department, Entry Pass Number and Time In. Mandatory requirements for personnel entry to sour facilities are shown below. Facility H2S Category Low Risk Sour High Risk Sour and Critical Sour Required for Entry Permit to Work Or Access Authorisation Form Or Asset Holder Exemption And H2S Entry Permit As for Low Risk Sour And Buddy System to be in force (PR-1081 – The Buddy System) Training Required Safety Induction. As for Low Risk Sour And H2S Awareness Escape Course. Safety Equipment Required and Personal H2S Gas Detector (PDO Approved) As for Low Risk Sour And Respiratory Protective (Escape) Equipment (RPE). 2.6 Numbers Permitted to Enter (at any one instance) As a general rule the numbers of personnel that shall be allowed to be in a high risk sour facility at any one instance shall be limited to 20. However this shall be governed by the number of personal monitors and escape sets held at site. Where the work is classed as ‘non-routine work’ i.e. major overhaul of equipment, additional personnel may be permitted on site provided the following criteria are met: A documented Risk Assessment has been carried out And The extra manning levels have been sanctioned by the Area Production Coordinator And Required supervision is present and adequate for each team working in the restricted area Page 12 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 And An Activities Coordinator1 has been appointed when the number of persons in the restricted area exceeds 20. Non-essential work should be done offsite or deferred until a shutdown opportunity when the facility has been purged free of H2S. 2.7 Departure On completion of any work or access or visit to an H 2S designated location the station operator and the person(s) leaving shall ensure: The station entry register has been signed correctly H2S Entry Permit or ID has been removed from the control board Access authorisation form has been cancelled (if required) Permit to Work has been signed off and work status updated Failure to comply may result in unnecessary extensive rescue operations may be initiated if there is an emergency. 2.8 Work Outside of Facility Perimeter Fences Construction or modification work may require to be undertaken outside of the facilities boundary fences and in these instances due consideration shall be given to protecting the workforces from the effects of exposure to H2S in the event of an incident. All work conducted inside the Emergency Planning Zone shall be covered by a Permit to Work and effective communication methods with the main control room shall be maintained. Prior to the work commencing the Job HSE Plan (JHSEP) shall be completed which should consider the ‘worse case scenario’ of an H 2S leak. The plan should consider the area that would be affected ‘down wind’ of such an incident and the nature of the work being undertaken. Based on the JHSEP the following should be established: H2S monitoring of the area identified ‘at risk’ by the JHSEP An emergency response contingency plan Provision of rescue facilities if required Safety Awareness briefings for all staff at the start of each shift 1 The Activities Coordinator shall be responsible for continuous monitoring of the work being undertaken and shall STOP the work and evacuate the work site if unsafe conditions or practices are observed. Page 13 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 2.9 Revision: 4.1 Effective: May-12 Formal H2S Training Courses Two mandatory training courses for personnel at sour facilities are: H2S Awareness and Escape The course shall be required for all staff that enter H2S designated areas. The course addresses hazards associated with H2S, occupational exposure limits, detection and alarm systems and appropriate action to be taken should a personal or facility alarm sound. Self Contained Breathing Apparatus (SCBA) Training Provides personnel with knowledge and skills to be competent in the use of Breathing Apparatus2 (BA) and in search and rescue techniques. For more details refer to SP-1157 - HSE Specification – HSE Training. 2 A medical test declaring the person physically fit for the use of a SCBA should be completed in advance to SCBA training. Results should be shown to the trainer in advance. Page 14 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 3 H2S Safety and Emergency Response 3.1 Activities requiring BA Revision: 4.1 Effective: May-12 BA is required to be worn in a sour facility when performing any breaking of system containment until the work area has been tested for H2S and declared safe to proceed without BA (e.g. breaking flanges, opening of vessels, opening of pump casings, pipelines, etc). For any BA activity, the Buddy System shall apply (Refer to PR-1081 – The Buddy System) and the Buddy must remain at a safe vantage point to provide aid or response. BA is also required to be worn when: 3.2 Entering any Red Zone Any gas leak occurs, BA should be worn until mustered in a safe location Working in an area where the concentration of H2S in air has been tested > 5 ppm or where a build-up of H2S could exceed the TLV (e.g. bunded areas and low-level areas). Refer to PR-1148 – Entry into a Confined Space. Performing wellhead activities, e.g. bleeding down to a pit, flowline operations etc. where H2S may be present in gaslift systems. Performing any sour sampling activity (refer to PR-1096 - Sampling of Oilfield Liquids and Gases Procedure) H2S Detection H2S detection is used to provide early warning to personnel to the presence of H2S in a facility or workplace. Either of the following H2S detection methods can be selected for the activity and hazards: Continuous gas monitoring in the immediate vicinity of the work using a properly calibrated and maintained H2S monitoring device (personal, portable or fixed). Intermittent measurements taken before and periodically during the work using a properly calibrated and maintained electronic H2S monitoring device or colorimetric detector tubes suitable for the range expected to be encountered. This method is also typically used during turnarounds when multiple concurrent activities may be executed in an area without fixed H2S detection. Fixed Systems Fixed detection systems are recommended when hazard assessment indicates a potentially high H2S risk. The location and installation of fixed systems are governed by SP-1190 - Design For Sour Service Specification A fixed system does not in itself provide protection for personnel. It should not therefore be considered a substitute for normal entry precautions to a high-risk area. Portable Detectors (Personal H2S monitors) These are used to alert the worker of a pre-set concentration of H2S, usually 10 ppm. They shall be used in an area where it is not practical to install fixed detectors and/or as a backup to fixed systems. They shall have an audible and visual alarm, which activates if the pre-set limit is exceeded and shall continuously display the current concentration. Personal monitors must be calibrated every 6 month in order to function properly. Users shall verify the unit is not out of calibration and perform the function test prior to use. Refer to requirements in SP-1234 - HSE Specification - Personal Protective Equipment Page 15 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 3.3 Revision: 4.1 Effective: May-12 Alarms and Mustering All personnel in the restricted area shall respond as follows in the event of a personal H2S alarm being activated: 1. The person wearing the affected personal monitor shall evacuate the area immediately and don their escape equipment if available. On leaving the area the station operator shall be informed immediately of the incident. 2. The station operator shall: Activate the facility H2S alarm Initiate the H2S emergency response Notify the CCR of the H2S emergency by dialling 5555 Alert his ‘Buddy’ Collect the Station Entry logbook and all IDs / H2S Entry Permits Proceed to designated Muster Point to perform head count, identify persons at the Muster Point and return their Entry Permits / ID cards. Should any permits remain, he shall check with the logbook to verify their presence within the station, and initiate rescue procedures Return to the station control room as quickly as possible to coordinate and lead any emergency response activity required 3. On hearing H2S alarm or the ‘personal monitor alarm’ all personnel in the restricted area shall proceed immediately to designated Muster Point (upwind or across the wind from the leak source) and adhere to any instructions given to them by the station operator. 4. The station operator and an assistant in full 35-minute breathing apparatus shall affect any required rescue. In the event that trained personnel (e.g. Fire and Safety) are already affecting the search and rescue, station operator and an assistant (still wearing full BA) shall attempt to locate the leak and isolate it. If this cannot be done quickly and safely the plant must be shut down completely. Consultation with the LEBC is first required to determine the safest course of action. Emergency Response procedures are outlined in CP-123 - Emergency Response Documents Part I - CoP. 3.4 Rescue Rescue procedures are outlined in CP-123 - Emergency Response Documents Part I CoP. 3.5 Emergency Procedures and Drills Emergency Response Drills shall be conducted regularly to give all affected personnel the opportunity to practice the emergency response procedures. The requirement for Drills is outlined in CP-123 - Emergency Response Documents Part I - CoP. Page 16 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 4 Safe Worksite Practices in H2S Facilities 4.1 Job Planning, Hazard Identification and Assessment Revision: 4.1 Effective: May-12 It is the responsibility of the Permit Applicant and Responsible Supervisor to ensure a Job HSE Plan is produced to identify the activity related hazards. It is the responsibility of the Permit Holder to ensure a quality Toolbox Talk and Risk Identification (TRIC) discussion takes places where the Job Safety Plan is discussed with the work party, and any additional hazards recorded on the TRIC form. The Job HSE Plan shall include but not limited to: Sequential analysis of the task execution and the potential hazards involved The potential sources of H2S under normal and upset conditions (planned and unplanned or emergency releases), Events that might release H2S into the work area, The maximum concentration of H2S in the process stream(s) and the maximum concentration that might result in the work area, in the event of accidental or anticipated releases, System integrity, reliability, and safeguards, including monitoring and alarm systems, The volume and H2S content of material that could be released, Process and monitoring data, and the validity of such data, especially in light of any changes, The activities involved in the planned work, their complexity, and duration, as well as any other relevant factors. The TRIC discussion should include the contents of the Job HSE Plan together with: Any potential where workers may be exposed to H2S in the course of their work. Warning signs and/or barricades at each point of access where there is a potential for H2S exposure. Testing and/or monitoring requirements. Compliance to relevant Corporate Procedures Emergency response in the event of H2S release. Access/egress – situations with limited access/egress and the potential for H2S exposure in confined spaces. The need for safety person(s), rescue equipment (including resuscitators), and hazard warning signs shall be considered when carrying out work involving H2S Careful attention shall be given to details, such as equipment checks, access / egress (escape) routes, and obstacles. In cases where the hazards have not been fully assessed and understood the job should not proceed Page 17 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC 4.2 Revision: 4.1 Effective: May-12 Permit to Work All work planned and executed in a sour facility shall be carried out in accordance with the Permit to Work (PTW) system. Refer to PR-1172, Permit to Work Procedure. Any activity involving Simultaneous Operations, or SIMOPS, shall be properly risk assessed and coordinated between the Permit Holders of the respective activities, with each attending the TRIC discussion for each activity. The following conditions shall be established as a minimum: 4.3 Coinciding events shall be analyzed by both job coordinators in advance and the agreed activities and control measures shall be captured on the PTW’s Separation distances between the simultaneous activities shall be established. Consult with the Technical Safety group if guidance is required A method of communication between the two simultaneous jobs shall be maintained to ensure awareness of hazards and progress at each site Isolation Procedures PR-1076 - Isolation of Process Equipment outlines the isolation requirements. Sour service equipment shall be properly isolated from service, all toxic fluids drained to a safe location, gas freed with inert gas, and checked for residual sour gas content prior to opening. Breathing apparatus shall always be worn when breaking any system integrity until the system has been deemed safe. Note that sour service equipment can contain an iron sulphide layer on the inner pipe wall, vessel wall, or internal components. Iron sulphide is pyrophoric, meaning it can spontaneously combust in the presence of oxygen, therefore attention shall be paid to managing this hazard. PR-1077 - Preparation of Static Equipment for Internal Maintenance and Inspection provides further details 4.4 Purging and Returning Equipment to Service Following any breaking of integrity, equipment to be returned to service shall: 4.5 Have all flanges correctly assembled and torque in accordance with SP-2020 Be purged with inert gas to remove any oxygen, and a reinstatement leak test carried out in accordance with PR-1073 - Gas Freeing, Purging & Leak Testing of Process Equipment Sample Points and Safe Sampling Sampling of sour fluids requires a properly designed sample point that allows a trained technician to safely draw a sample. Requirements for sour sampling and sample points are detailed in PR-1096 Sampling of Oilfield Liquids and Gases Procedure Page 18 Breathing apparatus and the buddy system shall always be used when sampling Proper access and egress shall be provided for the sample location to enable safe work practices and minimize hazards PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 Appendix 1 - Abbreviations CCR Central Control Room ERP Emergency Response Procedure IDLH Immediately Dangerous to Life and Health JHSEP Job HSE Plan LEBC Local Emergency Base Controller PTW Permit to Work SCBA Self Contained Breathing Apparatus SIMOP Simulaneous Operations SRB Sulphate Reducing Bacteria TLV Threshold Limit Value TRIC Toolbox Talk and Risk Identification Page 19 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 Appendix 2 – Reference Material Code of Practice CP-123 - Emergency Response Documents Part I - CoP Specification SP-1157 - HSE Specification – HSE Training SP-1190 - Design For Sour Service Specification SP-1234 - HSE Specification - Personal Protective Equipment Procedures PR-1001e – Operations Procedure Temporary Variance, PR-1073 - Gas Freeing, Purging & Leak Testing of Process Equipment PR-1076 - Isolation of Process Equipment PR-1077 - Preparation of Static Equipment for Internal Maintenance and Inspection PR-1081 – The Buddy System PR-1096 - Sampling of Oilfield Liquids and Gases Procedure PR-1148 – Entry into a Confined Space PR-1172, Permit to Work Procedure Page 20 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Revision: 4.1 Effective: May-12 Petroleum Development Oman LLC Appendix 3 - User Feedback Page PR-1078 – Hydrogen Sulphide (H2S) Management User Feedback Page Any user who identifies an inaccuracy, error or ambiguity is requested to notify the custodian so that appropriate action can be taken. The user is requested to return this page fully completed, indicating precisely the amendment(s) recommended. Name: Ref ID Page Ref: To: Date: Brief Description of Change Required and Reasons UOP 6 Custodian of Document Page 21 Date: PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED. Petroleum Development Oman LLC Revision: 4.1 Effective: May-12 Interim Amendment 1078_0512_01 This procedure has been aligned with SP-1190 – Design for Sour Services last updated September 2011. The key reference is Section 2.2 Levels of Concern. The changes at this interim amendment shall be incorporated when the procedure is next updated. The key change is the lowering of the Threshhold Level value (TLV) from 10ppm to 5ppm. It will be noted that this exposure change only effects the limit allowed for the standard working day which is taken to be 8 hours. The change does not affect the setpoint alarm of the personal H2S detector which still remains at 10ppm. The Short Term Exposure Level (STEL) shall also remain at 10ppm. This change will be will reflected in all other documentation where it occurs. Page 22 PR-1078 - Hydrogen Sulphide (H2S) Management Printed 10/05/11 The controlled version of this CMF Document resides online in Livelink®. Printed copies are UNCONTROLLED.