Audit Working Paper

advertisement

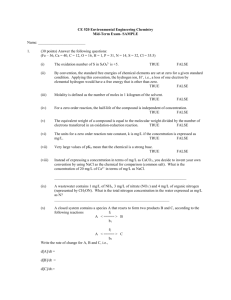

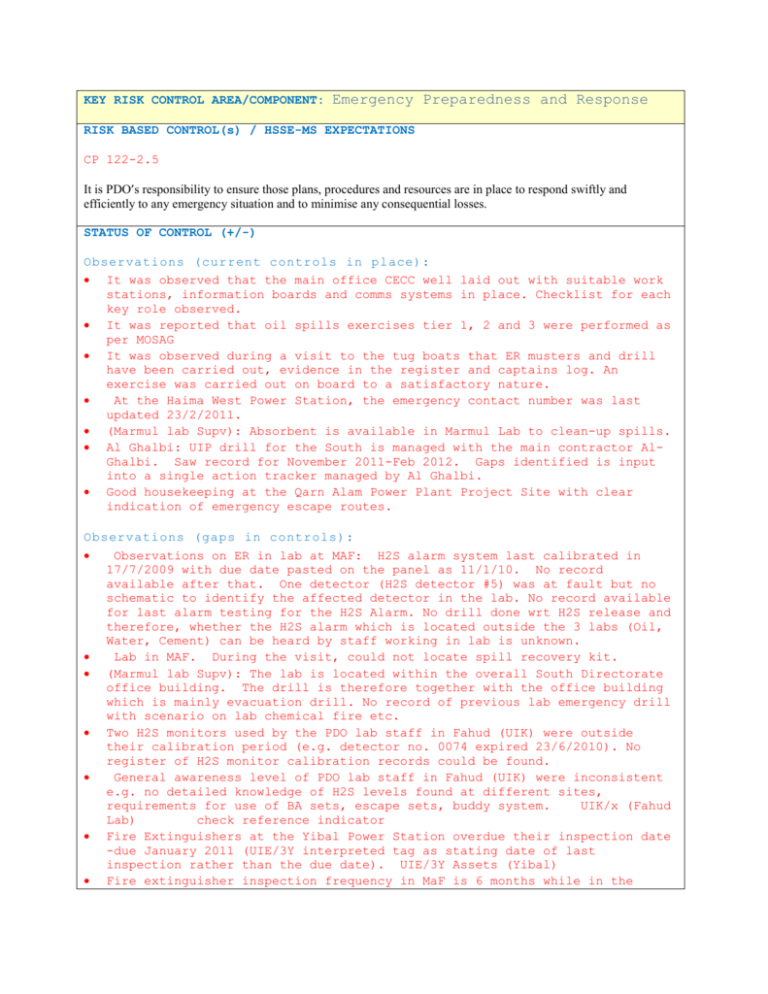

KEY RISK CONTROL AREA/COMPONENT: Emergency Preparedness and Response RISK BASED CONTROL(s) / HSSE-MS EXPECTATIONS CP 122-2.5 It is PDO’s responsibility to ensure those plans, procedures and resources are in place to respond swiftly and efficiently to any emergency situation and to minimise any consequential losses. STATUS OF CONTROL (+/-) Observations (current controls in place): It was observed that the main office CECC well laid out with suitable work stations, information boards and comms systems in place. Checklist for each key role observed. It was reported that oil spills exercises tier 1, 2 and 3 were performed as per MOSAG It was observed during a visit to the tug boats that ER musters and drill have been carried out, evidence in the register and captains log. An exercise was carried out on board to a satisfactory nature. At the Haima West Power Station, the emergency contact number was last updated 23/2/2011. (Marmul lab Supv): Absorbent is available in Marmul Lab to clean-up spills. Al Ghalbi: UIP drill for the South is managed with the main contractor AlGhalbi. Saw record for November 2011-Feb 2012. Gaps identified is input into a single action tracker managed by Al Ghalbi. Good housekeeping at the Qarn Alam Power Plant Project Site with clear indication of emergency escape routes. Observations (gaps in controls): Observations on ER in lab at MAF: H2S alarm system last calibrated in 17/7/2009 with due date pasted on the panel as 11/1/10. No record available after that. One detector (H2S detector #5) was at fault but no schematic to identify the affected detector in the lab. No record available for last alarm testing for the H2S Alarm. No drill done wrt H2S release and therefore, whether the H2S alarm which is located outside the 3 labs (Oil, Water, Cement) can be heard by staff working in lab is unknown. Lab in MAF. During the visit, could not locate spill recovery kit. (Marmul lab Supv): The lab is located within the overall South Directorate office building. The drill is therefore together with the office building which is mainly evacuation drill. No record of previous lab emergency drill with scenario on lab chemical fire etc. Two H2S monitors used by the PDO lab staff in Fahud (UIK) were outside their calibration period (e.g. detector no. 0074 expired 23/6/2010). No register of H2S monitor calibration records could be found. General awareness level of PDO lab staff in Fahud (UIK) were inconsistent e.g. no detailed knowledge of H2S levels found at different sites, requirements for use of BA sets, escape sets, buddy system. UIK/x (Fahud Lab) check reference indicator Fire Extinguishers at the Yibal Power Station overdue their inspection date -due January 2011 (UIE/3Y interpreted tag as stating date of last inspection rather than the due date). UIE/3Y Assets (Yibal) Fire extinguisher inspection frequency in MaF is 6 months while in the frequency in Yibal, Fahud and Qarn Alam is every 3 months MaF vs Interior NA Smoke detectors installed in the offices used by the Qarn Alam Power Station Projects, did not work. Jahnpars & Mapna (MD2) Consortium (UIE/53 Contractor) NA POTENTIAL FINDINGS There are gaps in the preparedness to respond in case of emergencies at the lab. There are also improvements for fire equipment maintenance. This was evidenced by Overdue calibration of H2S monitors and alarms in the lab Lack of spill recovery kit in lab Emergency drills not covering relevant potential scenarios for the lab Inconsistent identification of inspection dates of portable fire extinguisher maintenance Smoke detectors in Contractor office not working. ______________________________________________________________________________ ________________ Degree of weakness / materiality of flaw in control : Is control completely missing or is flawed to extent that it is effectively not functioning? No Is a control in place but has a material flaw? Control is in place, but gaps exist. Is there a gap likely to have a measurable undesirable impact on the achievement of one of the entity’s HSSE&SP objectives and therefore warrants remedial actions to be taken. ______________________________________________________________________________ ________________ Rating: MEDIUM ______________________________________________________________________________ ________________ Cross checks: To what sort of incident could such a gap in controls lead e.g. has a material flaw in application of MoC for organization played a key contributory role in prior incident(s) that could be classified in the RAM Yellow or RAM Red categories? Or What does the auditees risk register rank as? Does such a control gap warrant remedial actions to be taken in a short term time frame with oversight of the follow-up of these actions at the level of Business Leadership Team (i.e MDC level)? IMPLICATION(S) Laboratories may not detect and respond to emergencies to make timely response if the detectors, alarms are not in good calibration/ maintenance. Confusion in fire extinguishers inspection status may leave the response RECOMMENDATION(S) 1) Identify safety critical elements including detectors and alarms in the laboratory and include in SAP for maintenance and monitoring. 2) Evolve procedure for inspection, maintenance and identification of inspection status tagging of Portable fire extinguishers.