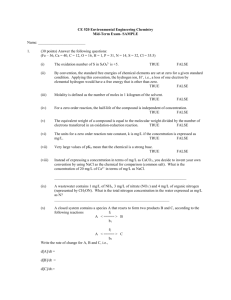

CEE 755

advertisement

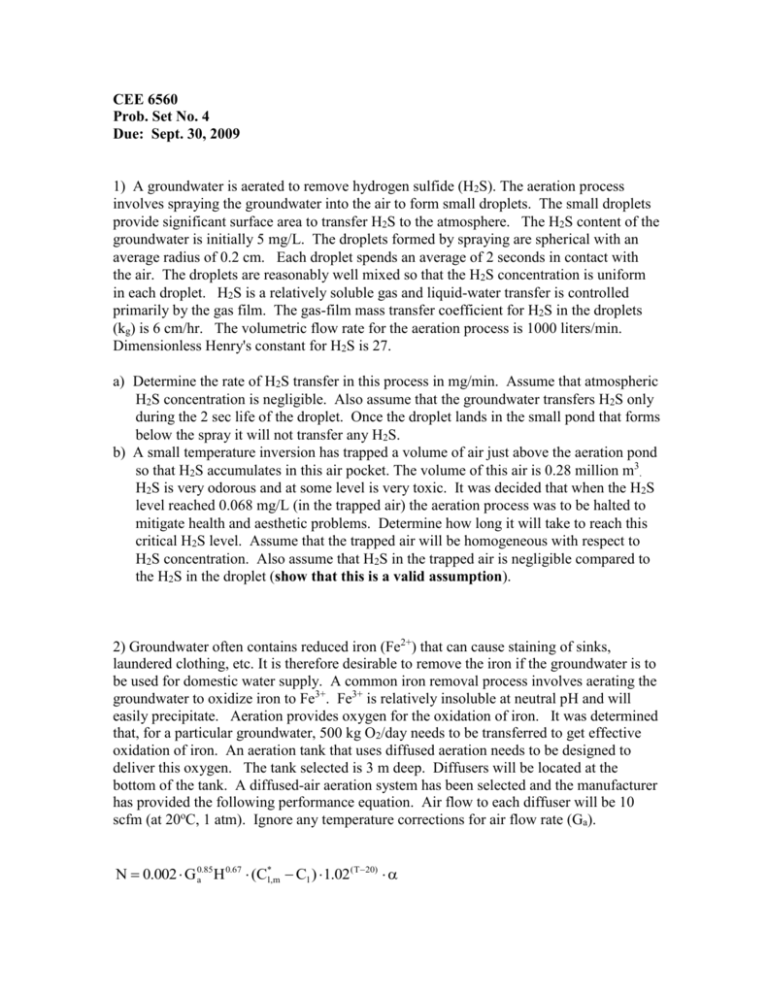

CEE 6560 Prob. Set No. 4 Due: Sept. 30, 2009 1) A groundwater is aerated to remove hydrogen sulfide (H2S). The aeration process involves spraying the groundwater into the air to form small droplets. The small droplets provide significant surface area to transfer H2S to the atmosphere. The H2S content of the groundwater is initially 5 mg/L. The droplets formed by spraying are spherical with an average radius of 0.2 cm. Each droplet spends an average of 2 seconds in contact with the air. The droplets are reasonably well mixed so that the H2S concentration is uniform in each droplet. H2S is a relatively soluble gas and liquid-water transfer is controlled primarily by the gas film. The gas-film mass transfer coefficient for H2S in the droplets (kg) is 6 cm/hr. The volumetric flow rate for the aeration process is 1000 liters/min. Dimensionless Henry's constant for H2S is 27. a) Determine the rate of H2S transfer in this process in mg/min. Assume that atmospheric H2S concentration is negligible. Also assume that the groundwater transfers H2S only during the 2 sec life of the droplet. Once the droplet lands in the small pond that forms below the spray it will not transfer any H2S. b) A small temperature inversion has trapped a volume of air just above the aeration pond so that H2S accumulates in this air pocket. The volume of this air is 0.28 million m3. H2S is very odorous and at some level is very toxic. It was decided that when the H2S level reached 0.068 mg/L (in the trapped air) the aeration process was to be halted to mitigate health and aesthetic problems. Determine how long it will take to reach this critical H2S level. Assume that the trapped air will be homogeneous with respect to H2S concentration. Also assume that H2S in the trapped air is negligible compared to the H2S in the droplet (show that this is a valid assumption). 2) Groundwater often contains reduced iron (Fe2+) that can cause staining of sinks, laundered clothing, etc. It is therefore desirable to remove the iron if the groundwater is to be used for domestic water supply. A common iron removal process involves aerating the groundwater to oxidize iron to Fe3+. Fe3+ is relatively insoluble at neutral pH and will easily precipitate. Aeration provides oxygen for the oxidation of iron. It was determined that, for a particular groundwater, 500 kg O2/day needs to be transferred to get effective oxidation of iron. An aeration tank that uses diffused aeration needs to be designed to deliver this oxygen. The tank selected is 3 m deep. Diffusers will be located at the bottom of the tank. A diffused-air aeration system has been selected and the manufacturer has provided the following performance equation. Air flow to each diffuser will be 10 scfm (at 20oC, 1 atm). Ignore any temperature corrections for air flow rate (Ga). N 0.002 G 0a.85 H 0.67 (C*l,m Cl ) 1.02 (T20) N = lbs/hr of oxygen transferred per diffuser. Ga = air flow (standard cubic feet/min @ 20oC and 1 atm) H = depth of diffuser, ft. C*l,m mid-depth oxygen saturation, mg/L Cl = operating dissolved oxygen concentration, mg/L Since this performance equation represents an empirical correlation the units of the equation parameters must be as described above. Assuming that the groundwater is essentially tapwater () and that the aeration tank dissolved oxygen level is to be maintained at 3 mg/L, determine the required number of diffusers to meet the oxygen demand. Assume that the aeration tank will be operated at sea level (1 atm pressure) and that the aeration system has a manufacturer’s efficiency rating of 0.2. Dissolved oxygen saturation at 25oC is 8.24 mg/L. 3) An aquifer has been contaminated with tetrachloroethane (PCE). The PCE concentration in the contaminated water is 10 g/L. The contaminated area has been hydraulically isolated using slurry walls. The contaminated aquifer water within the slurry walls is pumped out and treated in an air stripping column. This water is pumped for a time period long enough to draw down the aquifer to approximately 1/3 of its total water volume. Assume the stripping column attains steady state removal efficiency in a very short after start up. The liquid effluent from the air stripper is stored in closed tanks. After the 1/3 volume drawdown is accomplished treated water from the storage tanks is pumped back into the contaminated aquifer. Withdrawal and recharge of the contaminated aquifer water is accomplished with multiple wells so that the contaminated aquifer exhibits completely mixed behavior. Determine the concentration of tetrachloroethane (PCE) in the aquifer after three (3) treatment cycles. PCE: H (Henry's constant) 7 103 atm m3 mol R 8.21105 m3 atm mol o K Kla = 0.02 per min Stripping column: A = 1.5 m2 Length = 4 m Air flow rate = 1000 liters/min Aquifer: depth = 10 m Water pump rate = 75 liters/min T = 293 oK area = 1500 m2 porosity () = 0.25