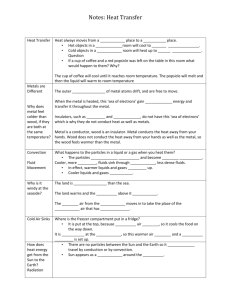

Nanoparticle stabilization via scalable ALD/MLD coating

advertisement

Title: Nanoparticle stabilization via scalable ALD/MLD coating process Participants: Miao Yu and John R. Regalbuto Motivation: Heterogeneous catalysts are used to manufacture most chemicals (e.g., making gasoline from petroleum1, producing fertilizers2, controlling automotive exhaust pollution via the catalytic muffler3). Many catalysts used on a large scale consist of small metal particles dispersed on a high surface area support, which helps maximize the number of metal atoms on the surface; only the top atomic layer of metal atom is involved in catalytic reactions. Since the metals that are good catalysts (Pt, Ru, Pd, etc.) are also expensive, a large fraction of the metal atoms must be surface atoms for their economical use. The metal particles, therefore, are small (<10 nm), so that a large fraction of the metal atoms are on the surface and thus available to adsorb reactant molecules and catalyze reactions. A significant problem with using small metal particles as catalysts is they lose their activity over time. Sintering of nanoparticles at elevated temperatures and under various environments is one of the most important reasons of activity loss. Recent studies demonstrated that sintering of unsupported metal particles can be dramatically reduced by an oxide coating. Joo et al.4 coated individual, unsupported metal nanoparticles of platinum (Pt) with a porous oxide layer. They reported that 14-nm Pt nanoparticles, when coated with a 17-nm thick, mesoporous silica shell by a sol-gel process, sintered much slower. Because their silica layer was porous, reacting molecules could access the Pt surface, but the silica layer prevented Pt particles from contacting each other. The oxide coating inhibited sintering so that the Pt core/silica shell particles could be heated to 750oC. Without the silica coating, the Pt particles could only be heated to 300oC. This is a dramatic increase in stability. Similarly, Arnal et al.5 encapsulated unsupported Au nanoparticles in hollow, porous zirconia spheres by first coating Au nanoparticles with dense silica, coating this composite with zirconia nanoparticles that formed 3-nm pores, and then leaching out the silica so that the Au nanoparticles were released. These catalysts had similar CO oxidation activity after treatment at 800oC, indicating that the porous zirconia spheres prevented sintering of the Au nanoparticles. These two studies show that an oxide coating dramatically decreased the rate of catalyst particle sintering for unsupported metal particles, but such particles are not used for commercial catalytic reactions because: Although 14-nm Pt particles are small, they are larger than the metal particles supported on porous oxides of actual catalysts. Supported catalysts are typically used in packed bed reactors, and catalyst pellets are 0.5 to 1.0 cm in diameter so that the pressure drop across the bed is not too large. Unsupported metal particles are much less stable than supported ones and cannot be readily utilized on a large scale. Porous coating Moreover, methods used to coat unsupported metal particles cannot be used to coat high surface area catalysts. Because the metal nanopartiles are not porous, the methods only were required to coat the external surface. For a porous catalyst pellet, such methods would Catalyst block the pores of the supports and drastically reduce the catalyst surface area. particle Molecula Porous coating OH OH O Based on these previous studies, a Support porous oxide coating on supported metal nanoparticles, as shown in Figure 1, Figure 1: Cross-section of supported metal therefore, may have great potential to prevent nanoparticles with a thin porous coating to (a) (b) them from sintering while allowing reactants to prevent sintering. OH OH A: OH* + Al(CH3 CH3 CH3 CH3 CH3 CH3 Al O B: Al O O Al AlCH3* + OHCH reach metal surface. Molecular layer deposition (MLD) is a gas phase deposition process and can be used to prepare ultrathin (<10 nm), conformal porous metal oxide coatings (Al2O3, TiO2, SiO2, etc.) on various substrates6-8. It may have great potential to deposit porous coatings with controllable composition, thickness, and pore sizes on a wide range of metal nanoparticles in a scalable way, if devised appropriately, to prevent them from sintering. We propose to create a <10 nm thick, porous oxide coating on the entire catalyst surface (both the metal and the oxide support, Fig. 1) using MLD. Molecular layer deposition can deposit conformal coatings whose thicknesses are precisely controlled because two self-limiting reactions are used (see below). A nonporous metal-polymer layer will be deposited by MLD, and subsequent treatment will convert it to a porous oxide layer. Hypothesis: Our hypothesis is that such a thin coating will isolate the metal particles from each other so that they will not readily be able to contact neighboring metal particles and sinter. We also hypothesize that the oxide layer will not significantly affect the overall rate of catalytic reaction because it is so thin, and because it would have high porosity. Objective: Our goal is to dramatically decrease the rate of sintering so that the catalyst could be used for much longer times before being CH CH CH CH CH CH CH CH Al Al replaced, and/or they could be used at higher Al Al O O OH OH OH OH O O temperatures. We propose to use MLD to + Al(CH ) mimic the type of catalysts that were formed A: OH* + Al(CH3)3 OAl(CH3)2* + CH4 by Joo et al., but to form thinner oxide layers on supported metal nanoparticles instead of on unsupported nanoparticles. We will use MLD to create a thin metal-organic layer on CH CH CH CH CH CH CH CH Al Al the entire surface of a high surface area Al Al Al Al Al Al O O O O O O O O supported catalyst, isolating the metal + OHCH CH OH nanoparticles from each other. This metalorganic layer will then be converted to a B: AlCH3* + OHCH2CH2OH AlOCH2CH2OH* + CH4 porous oxide layer by subsequent treatment. The MLD technique is a recent variation of Figure 2: An example using molecular layer atomic layer deposition (ALD) 6 7 8. The ALD deposition (MLD) to form an aluminum hybrid film by repeat A-B self-limiting surface reactions and MLD layers are produced by sequentially conducting two half-reactions at the surface of a substrate; each half reaction stops when all the surface sites have reacted; they are self-limiting. Each set of half-reactions deposits a layer that conforms to the surface of the underlying substrate. By repeating the reaction sequence, a layer of any thickness can be deposited. This is a significant advantage over other methods. Figure 2 shows two half reactions to deposit aluminum hybrid coating that can be subsequently converted to microporous alumina, for example, by calcination in air. 3 3 3 3 3 3 3 3 3 3 3 3 3 2 OCH 2CH 2OH 3 OCH2 CH OH 2 OCH C 2 H OH 2 OC HC 2 H 2 OH O CH 2 CH O 2 H OCH2CH2OH 3 OCH C 2 H2 OH 3 H CH 2O OCH 2 3 3 2 Volume, cc/Å/g We will use MLD to deposit a <10 nm thick, metal-organic coating on supported metal nanoparticles. The resulting layer would then be oxidized to create a uniform porous coating that we hypothesize will completely coat the catalyst surface. We have used MLD to prepare ultra-thin, porous metal oxide films onto non-porous silica nanoparticles8. The metal-organic coating had a regular structure, and its oxidation produced a uniform porous structure with BET surface areas greater than 1,000 m2/g8. The sequential reactions of trimethyl aluminum (TMA) and ethylene glycol at 375 K (Fig. 2) formed the metal-polymer layers on dense SiO2 particles (Fig. 3). These layers were oxidized to form a Figure 3: Using MLD to form an microporous-mesoporous alumina coating with pore-size aluminum hybrid film by repeat A-B self-limiting reactions distributions centered at approximately 0.6 and 3.8 nm. The MLD method has significant advantages: 0.03 0.02 0.01 0 1 Thin layers (<10 nm) can be prepared. Coverage is conformal so the surface will be uniformly coated. Supports can be used with 30-nm pores or larger without significantly increasing the diffusion resistance. A catalyst with a surface area of 100 m2/g has 30-nm pores. Research Plan: We will use MLD to form thin (<10 nm) porous oxide layers on supported metal nanoparticles (Pt, Au, Ru, Pd, etc.) and study their effects on preventing metal nanoparticles from sintering. The MLD coating pores may also be closed by appropriate surface treatments of pore wall. The proposed research includes: 1) Characterize supported metal nanoparticles by SEM, TEM, ICP, N2 adsorption, and chemisorption before and after deposition of porous oxide layers to determine the catalyst composition, the oxide layer thickness, pore size, and surface area, and the fraction of the metal sites available for adsorption. Because the oxide layer deposits on both the metal surface and the support, the number of catalytic sites available for adsorption may decrease. 2) Measure how resistant these coated catalysts are to sintering. Catalysts without coatings will be treated at 700-800 oC until sintering is observed, as verified by TEM. The same conditions will be used for catalysts with MLD oxide coatings to determine how stable they are to sintering. We will also study the anti-sintering capability of MLD coated metal nanoparticles in different environments. For example, we have found significant sintering of Au nanoparticles supported on activated carbon when exposed to HCl during its reaction with acetylene to produce polyvinyl chloride (PVC), which is the third-most widely produced polymer. 3) The MLD conditions and the subsequent treatment to form the oxide layer will be varied to prepare catalysts with different oxide thicknesses. The objective is to make the oxide layer thin enough so that catalytic rate is the same, but thick enough to decrease sintering. 4) MLD layers of Al2O3, TiO2, ZnO, and SiO2 will be deposited on catalysts using various precursors to determine which is most effective in decreasing the sintering rate. 5) Study reaction activity and stability of metal nanoparticles with and without MLD, using industrially important reactions, such as PVC production from HCl and acetylene. other identified interested reactions will also be tested. First Year Deliverable: Successful demonstration of MLD coatings to prevent metal nanoparticles from sintering; identification of effective MLD coatings for maintaining catalyst reactivity and long term stability. First Year Milestone(s) 1) Months 1-6: Characterization of metal nanoparticles with and without MLD coatings after various treatments; demonstration of robust MLD coating for preventing sintering; 2) Months 7-12: measurements of reactivity and stability of MLD coated nanoparticles. Cost: $60,000 for one year. Funds are requested for one graduate student to perform experiments as outlined in the research plan and to assist in the collection and analysis of the data under the direct supervision of the PIs. Funds are also requested on materials, supplies and services related to this project in the first year. These include chemicals, glassware, gases, safety gloves, and other items used for conducting the experiments and characterization services (SEM, TEM, ICP, XRD, etc.). References 1. Golombok, M.; de Bruijn, J., Catalysts for producing high octane-blending value olefins for gasoline. Appl. Catal. A-Gen 2001, 208, (1-2), 47-53. 2. Singh, B., Treatment of spent catalyst from the nitrogenous fertilizer industry-A review of the available methods of regeneration, recovery and disposal. J Hazard Mater. 2009, 167, (1-3), 24-37. 3. Kaspar, J.; Fornasiero, P.; Hickey, N., Automotive catalytic converters: current status and some perspectives. Catal. Today 2003, 77, (4), 419-449. 4. Joo, S. H.; Park, J. Y.; Tsung, C. K.; Yamada, Y.; Yang, P. D.; Somorjai, G. A., Thermally stable Pt/mesoporous silica core-shell nanocatalysts for high-temperature reactions. Nat. Mater. 2009, 8, (2), 126-131. 5. Arnal, P. M.; Comotti, M.; Schuth, F., High-temperature-stable catalysts by hollow sphere encapsulation. Angew. Chem. Int. Ed. 2006, 45, (48), 8224-8227. 6. Adarnczyk, N. M.; Dameron, A. A.; George, S. M., Molecular layer deposition of poly(pphenylene terephthalamide) films using terephthaloyl chloride and p-phenylenediamine. Langmuir 2008, 24, (5), 2081-2089. 7. Dameron, A. A.; Seghete, D.; Burton, B. B.; Davidson, S. D.; Cavanagh, A. S.; Bertrand, J. A.; George, S. M., Molecular layer deposition of alucone polymer films using trimethylaluminum and ethylene glycol. Chem. Mater. 2008, 20, (10), 3315-3326. 8. Liang, X. H.; Yu, M.; Weimer, A. W., Ultra-thin microporous-mesorporous metal oxide films prepared by molecular layer deposition (MLD). Chem. Commun. 2009, 7140-7142.