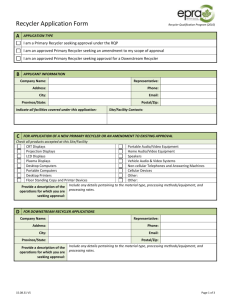

Recycler Qualification Program for End-of

advertisement