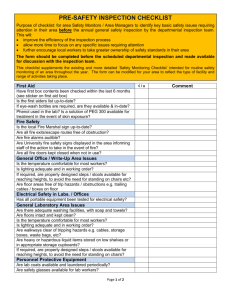

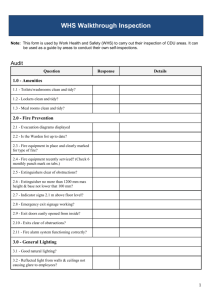

Safety Monitor checklist

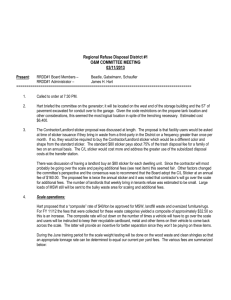

advertisement

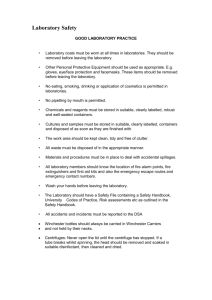

SAFETY MONITORING CHECKLIST (Modify and adapt, as appropriate, for your area) First Aid Have first box contents been checked within the last 6 months (see sticker on first aid box) Is the first aiders list up-to-date? If eye-wash bottles are required, are they available and in-date? Phenol used in the lab? Is a solution of PEG 300 available for treatment in the event of skin exposure? Fire Safety Is the local Fire Marshal sign up-to-date? Are all fire exits/escape routes free of obstruction? Are fire alarms audible? Are University fire safety signs displayed in the area informing staff of the action to take in the event of fire? Are all fire doors kept closed when not in use? Are the extinguishers ‘in date’ (check label for last inspection) Offices / Write Up Areas Is the temperature comfortable for most workers? Is lighting adequate and in working order? If required, are properly designed steps / stools available for reaching heights, to avoid the need for standing on chairs etc? Are floor areas free of trip hazards / obstructions e.g. trailing cables / boxes on floor? Electrical Safety in Labs. / Offices Has all portable equipment been tested for electrical safety Are there any trailing leads that could cause a trip hazard? Do the leads and plugs look in good condition? Is any item of electrical equipment defective in any way? Is the use of socket adapters, to allow multiple appliances to be plugged into a single wall outlet, kept to an absolute minimum? Have all laboratory fridges been spark-proofed? If not, contact the Infrastructure Team. General (Laboratory Areas) Are restricted access areas clearly marked with appropriate signs? Are general ventilation systems operating correctly? Is the temperature comfortable for most workers? Is lighting adequate and in working order? Are there adequate washing facilities, with soap and towels? Are floors clean and intact? Are workbenches intact and easily cleaned? Are walkways clear of tripping hazards e.g. cables, storage boxes, waste bags, etc Are heavy or hazardous liquid items stored on low shelves or in appropriate storage cupboards? If required, are properly designed steps / stools available for reaching heights, to avoid the need for standing on chairs? √/x Action Personnel Protective Equipment Are lab coats available and laundered periodically? Are safety glasses available for lab workers? Is the use of non-latex gloves (e.g. nitrile) encouraged and available? Is a UV protective face shield / glasses available if required? Lab Waste Disposal Are there appropriate containers for disposal of sharps? Are all bins for thick black bag ‘non-hazardous lab waste’ labelled? Are all bins for ‘hand towels only’ labelled? Are appropriate waste disposal routes used by workers? Is all lab waste removed promptly avoiding build-up? Is the departmental waste disposal poster displayed? Local Exhaust Ventilation Have all fume cupboards been tested within the last 12 months (look for sticker on unit to see when next test is due)? Are all microbial safety cabinets been tested within at least the last 12 months (check sticker on unit: when next test is due)? Are all cabinets kept clean and uncluttered? Gas Cylinders Are all gas cylinders secured by restraining chains, bench clamps or similar? Is the gas regulator <5 years old (check date on sticker)? Is there a cylinder valve key readily accessible? Is a local record kept of training provided to users of gas cylinders? Autoclaves Have all autoclaves (including bench top autoclaves) been examined and tested within the last 12 months (look for sticker on equipment) Microwave Ovens Are lab microwaves labelled with sticker promoting safe user practices? UV Transilluminators Is there a UV hazard warning label visible on the instrument? If exposure to UV is possible, is a UV protective face shield available and is this clearly labelled as UV protective? Chemicals Are flammables stored in a fire resistant labelled storage cabinet with spill trays? Are bottles containing strong acids or strong alkalis stored separately from flammables? Are bottles containing strong acids or strong alkalis stored on spill trays? Are toxins / poisons stored separately from other chemicals in a secure location (e.g. poisons cupboard)? Are waste solvents stored in labelled (labels available from Biology Stores), plastic coated bottles? Have all redundant chemicals been disposed of? Is an emergency chemical spillage kit available / adequately stocked & easily accessible? Legionella Control Have all infrequently used taps (<once/wk) been identified / labeled / flushing programme implemented and recorded? √/x Action Safety Monitoring Record Safety Monitors should periodically (recommended at least once every 2 months) check their areas for any health and safety issues requiring attention using the ‘Safety Monitors Checklist’ as a guide. This form should be completed to record any issues you have identified requiring attention and to confirm that that monitoring has taken place. Date Observations / Issues Action Required / Taken Signature / Initials