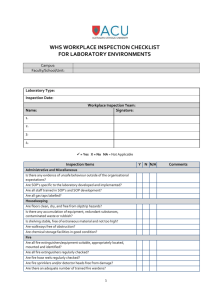

WHS Walkthrough Inspection

advertisement

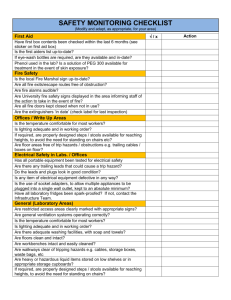

WHS Walkthrough Inspection Note: This form is used by Work Health and Safety (WHS) to carry out their inspection of CDU areas. It can be used as a guide by areas to conduct their own self-inspections. Audit Question Response Details 1.0 - Amenities 1.1 - Toilets/washrooms clean and tidy? 1.2 - Lockers clean and tidy? 1.3 - Meal rooms clean and tidy? 2.0 - Fire Prevention 2.1 - Evacuation diagrams displayed 2.2 - Is the Warden list up to date? 2.3 - Fire equipment in place and clearly marked for type of fire? 2.4 - Fire equipment recently serviced? (Check 6 monthly punch mark on tabs.) 2.5 - Extinguishers clear of obstructions? 2.6 - Extinguisher no more than 1200 mm max height & base not lower that 100 mm? 2.7 - Indicator signs 2.1 m above floor level? 2.8 - Emergency exit signage working? 2.9 - Exit doors easily opened from inside? 2.10 - Exits clear of obstructions? 2.11 - Fire alarm system functioning correctly? 3.0 - General Lighting 3.1 - Good natural lighting? 3.2 - Reflected light from walls & ceilings not causing glare to employees? 1 Question Response Details 3.3 - Light fittings clean and in good condition? 3.4 - Windows clean? 3.5 - Area free of flickering, damaged or inoperable lights? 4.0 - Building Structure and Safety 4.1 - Floor surfaces even and uncluttered? 4.2 - Entry and walkways kept clear? 4.3 - Walkways adequately and clearly marked? 4.4 - Steps are in good order (No worn or broken steps)? 4.5 - Stair and risers kept clear? 4.6 - Are railings in good condition? 4.7 - Are footpaths in good condition? 4.8 - Is asbestos labelled or signed in accordance with the Code of Practice - How to manage & control asbestos? 4.9 - Loading area clean and tidy? 4.10 - Area free of Structural defects/faults? 4.11 - Confined space management compliant with Code of Practice - Confined Spaces? 4.12 - Is area free of leaks? 4.13 - Ventilation/air temperature acceptable? 5.0 - Work Benches 5.1 - Clear of rubbish? 5.2 - Tools not in use are stored correctly? 5.3 - All hand tools being used are in good order and free of damage? 5.4 - All power tools being used are in good order, free of damage? 5.5 - Work height correct for the type of work and the employee? 2 Question Response Details 5.6 - Benches are free of sharp edges? 6.0 - Rubbish Removal 6.1 - Bins located at suitable points around site? 6.2 - Bins emptied regularly? 6.3 - Oily rags and combustible refuse in covered metal containers? 7.0 - Material Storage 7.1 - Racks and shelving are sturdy and stable? 7.2 - Materials stored in racks and bins wherever possible? 7.3 - Mechanical aids provided for safe access to stored equipment eg. Ladders, forklift 7.4 - Floors around racking clear of rubbish? 7.5 - Heavier items stored low? 7.6 - Sufficient space for moving stock? 7.7 - Pallets in good repair? 7.8 - No danger of falling objects? 7.9 - Shelves and racks free of sharp edges? 7.10 - Racks clear of lights/sprinklers? 7.11 - Shelves are clean and orderly? 7.12 - Items flagged for disposal stored safely? 7.13 - Stock / material stored safely? 8.0 - Machines 8.1 - Are they kept clean? 8.2 - Are the floors around the machines kept clean? 8.3 - Guards in good condition? 8.4 - Starting and stopping devices within easy reach of operator? 3 Question Response Details 8.5 - Waste/off cuts removed and stored safely? 8.6 - Area free from excess oil and grease? 8.7 - Adequate work space? 8.8 - Is lighting adequate? 8.9 - Noise levels controlled? 8.10 - Warnings/instructions/SOP's displayed? 8.11 - Location of emergency stop buttons indicated by signage? 8.12 - Operators trained/inducted into the operation of the machines? 8.13 - Is the training recorded? 8.14 - Are lockout procedures implemented and followed during adjustments and servicing? 9.0 - Electrical Safety 9.1 - Safety switches installed? 9.2 - All 240v electrical equipment is tested every 6/12 months and tests recorded? 9.3 - Power boards used (no double adapters)? 9.4 - No work near exposed live electrical equipment? 9.5 - Plugs, sockets & switches in good order? 9.6 - Are areas free of cable/lead trip hazards? 9.7 - Frayed, strained or damaged leads have been tagged and removed from use? 9.8 - Switchboards secured? 9.9 - Danger tags completed and in place for defective electrical equipment? 9.10 - Where required are emergency shut-down procedures in place? 4 Question Response Details 10.0 - Hazardous substances and dangerous goods 10.1 - Hazardous Substance Register complete and available? 10.2 - Safety Data Sheets available for all chemicals? 10.3 - Risk assessments completed for hazardous substances? 10.4 - All containers labelled correctly according to appropriate legislation? 10.5 - Does area have a procedure for disposal of unwanted & waste substances? 10.6 - Stored in accordance with appropriate legislation / standards - chemical segregation? 10.7 - Fridges, freezers and cool rooms used for chemical storage are clearly labelled? (Including statement about no foodstuffs) 10.8 - Refrigerators used to store flammable materials are flame proofed and appropriately labelled? 10.9 - PPE and emergency equipment (safety showers and eye wash station) available and tested regularly? 10.10 - Adequate ventilation / extraction systems available for processes used, eg fume and biological cabinets? 10.11 - Flammable, toxic and asphyxiant gases used in areas designed for that purpose with appropriate controls, sensors or ventilation? 10.12 - Appropriate containers are used to hold and store hazardous chemicals? 10.13 - Hazardous chemicals are not stored in fume or recirculating fume cabinets? 10.14 - Spill kits appropriate to the work being undertaken are available and maintained? 10.15 - Appropriate carriers are available to transport dangerous goods, eg Winchester carriers for 2.5L bottles of acid? 5 Question Response Details 10.16 - Dewars less than 25L have handles and loose fitting lids? 10.17 - Cryogenic storage areas have appropriately sensors or ventilated? 11.0 Ladders 11.1 - Are all ladders of sturdy construction? 11.2 - Are ladders in good condition? 11.3 - If used for electrical work are they non conductive? (Wood or fibre glass.) 11.4 - Set up and used according to instructions, eg secure at top, extending 1m above working platform, correct angle (1:4) 11.5 - For extension ladders are ropes, pulleys and treads in a good state of repair? 12.0 - First Aid Facilities 12.1 - Record of treatments and supplies dispensed available? 12.2 - Are contents regularly checked? 12.3 - Are all contents within their expiry date? 12.4 - First Aid Kits clearly labelled and well signed? 12.5 - Is there easy access to cabinets? 12.6 - Are first aid officers accessible? 13.0 - Office Hazards 13.1 - Furniture layout is appropriate and adequate? 13.2 - Condition of chairs? (Five star bases.) 13.3 - Desks in good condition? (No damage.) 13.4 - Are work stations uncluttered - free of stored items on floor or under desk? 13.5 - Air conditioning systems regularly maintained? 6 Question Response Details 13.6 - Stable non-slip floor coverings in good condition? 14.0 - Plant and equipment 14.1 - Schedule maintenance performed? 14.2 - Condition of tyres? 14.3 - Plant and equipment in good condition? 14.4 - Appropriate registration/certification displayed and valid? (No sticker required for vehicles with GVM of 4.5 tonnes or less) 14.5 - Warnings / instructions / SOPs displayed? 14.6 - SWL of lifting or carrying equipment is displayed? 15.0 - Outside areas 15.1 - Surrounding grounds are free of rubbish lying on ground? 15.2 - Vehicles parked only in designated parking areas? 15.3 - Excavation areas cordoned off? 16.0 - Personal Protective Equipment (PPE) 16.1 - PPE is available, in good condition and stored appropriately? 16.2 - No defective/worn/ damaged PPE observed? 16.3 - Mandatory PPE signage displayed for work areas? 17.0 - Gas cylinders, cylinder storage and reticulated gases 17.1 - Cylinders are stored in accordance with legislation: segregation, secured, etc. 17.2 - Cylinder storage areas have Hazchem storage signage? 17.3 - Cylinders are within stamped 10 year expiry date? 7 Question Response Details 17.4 - Regulators, piping, hoses, etc are appropriate for the gas being used and are well maintained? 17.5 - Only in-use cylinders are in work areas and securely fixed to trolleys? 17.6 - Reticulated gas systems have isolation values clearly marked and accessible? 17.7 - Reticulated gas system emergency stops buttons are clearly marked and accessible? 17.8 - Empty cylinders are separated from full cylinders and clearly labelled? 17.9 - Appropriate resources are available for transporting gas cylinders? 18.0 - Welding (oxy-acetylene, arc, Mig) 18.1 - Appropriate fume extraction systems / ventilation in place for all welding processes? 18.2 - Only flint lighter / pilot lights used to ignite torches? 18.3 - Flash back spark arrestors fitted? 18.4 - Vision screens in good condition for arc or MIG welding? 19.0 - Laboratories 19.1 - Appropriate signage displayed for laboratories, (e.g. PC2 facility, authorised entry only,etc.)? 19.2 - Safe Work Procedures are developed, approved and available to lab users 19.3 - Scientific equipment and instrumentation is in good condition? 19.4 - Workbench surfaces appropriate for task and undamaged? 19.5 - Laboratory stools/chairs are appropriate to the work area and in good condition? 19.6 - Laboratory coats/gowns are stored in a manner that prevents cross contamination? 8 Question Response Details 19.7 - Appropriate waste containers ( e.g. sharps bins, biohazard bins) available and clearly marked? 19.8 - Hand washing facilities are appropriate (eg. Hands free in PC2) and adequate to service the area? 19.9 - A supply of disinfectant is available for decontamination purposes for biological work, preparation date displayed? 19.10 - Separate work and storage areas are provided within the laboratory for administrative purposes? Prepared by (name of inspector) Inspection conducted on (date) 9