Course Descriptor Template - Heriot

advertisement

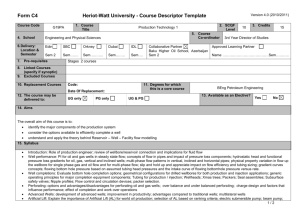

Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Course Code 1. Course Title G10DP 2. SCQF Level Production Technology 5. Course Co-ordinator 4. School Engineering and Physical Sciences 6. Delivery: Location & Semester Edin SBC Orkney Dubai IDL Sem 2 Sem……. Sem……….. Sem…….. Sem…. Collaborative Partner Baku Higher Oil School, Azerbaijan Sem 2 10 3. Credits 150 4th Year Director of Studies Approved Learning Partner Name …………………………………Sem……….. 7. Pre-requisites 8. Linked Courses (specify if synoptic) 9. Excluded Courses 10. Replacement Courses Code: 11. Degrees for which this is a core course Date Of Replacement: 12. The course may be delivered to: UG only PG only UG & PG BEng Petroleum Engineering 13. Available as an Elective? Yes No 14. Aims The overall aim of this course is to: identify the major components of the production system consider the options available to efficiently complete a well understand and apply the theory behind Reservoir – Well – Facility flow modelling examine the techniques available to enhance production from both reservoir and well design appropriate procedures to ensure optimal initial production understand the process of delivering and treating reservoir and injection fluid at the surface 15. Syllabus Introduction: Role of production engineer; review of wellbore/reservoir connection and implications for fluid flow Well performance: PI for oil and gas wells in steady state flow; concepts of flow in pipes and impact of pressure loss components; hydrostatic head and functional pressure loss gradients for oil, gas, vertical and inclined wells; multi-phase flow patterns in vertical, inclined and horizontal pipes; physical property variation in flow up the wellbore for single phase gas and oil flow and for multi-phase flow; slip and hold up and appreciate impact on flow efficiency and tubing sizing; gradient curves concepts; flowing bottom hole pressure based on assumed tubing head pressures and the intake curve of flowing bottomhole pressure versus rate. Well completions: Evaluate bottom hole completion options; geometrical configurations for drilled wellbores for both production and injection applications; generic operating principles for major completion equipment components; Tubing for production / injection; Wellheads; Xmas trees; Packers; Seal assemblies; Subsurface safety valves; Nipple profiles; Flow control and circulation devices; packer selection. 1/3 Form C4 Heriot-Watt University - Course Descriptor Template Version 4.0 (2010/2011) Perforating: options and advantages/disadvantages for perforating oil and gas wells; over balance and under balanced perforating; charge design and factors that influence performance; effect of completion and work over operations Advanced Wells: development of advanced wells; improvement in productivity; advantages compared to traditional wells; multilateral wells Artificial Lift: Explain the importance of Artificial Lift (AL) for world oil production; selection of AL based on ranking criteria; electric submersible pump; beam pump; fluid driven hydraulic pumps (Explain the mode of operation of the(i) Jet pump;(ii) Weir Multiphase pump;(iii) Hydraulic pump); progressive cavity pump Gas Lift: Describe the gas lift process; Identification of application areas/advantages for gas lift; well unloading process; gas lift hardware components; gas lift completion design; intermittent gas lift and plunger lift processes. Formation Damage: formation damage and poor well performance; major sources of formation damage; appropriate remedial treatments; production related formation damage; scale, wax, asphaltene deposition; scale inhibitors; perforating damage Matrix Acidising: Types of matrix stimulation techniques; primary chemical reactions in sandstone and carbonate acidising. Acid selection; Additives; Acidising treatment design Hydraulic Fracturing: Productivity Increase Factor (PIF) achievable by HF; role of Rock Mechanics in supplying basic design data for an HF treatment; Fracture Propagation Pressure Record analysis to derive basic design data; Fracture Propagation Models; Hydraulic Fracture geometry (fracture shape and length); Hydraulic Fracture Treatment Design Procedure; Hydraulic Fracturing Treatment operation Sand Control: Decision to install sand control during the original completion design; definition of sand problem in the field; Surface equipment/operations to cope with sand production; sand control options; liner/screen design; gravel pack design; Field Development Concepts & Fluid Processing: design and operation of the production facilities; outline production process scheme; components and operation of a 3 phase separator; fiscal measurement of produced cride oil; pipeline “pigging” operation; gas handling facility - NGL separation and stabilisation, gas dehydration and sweetening, chemical composition of formation water; operational problems (scale, corrosion, etc); oily water treatment; disposal options; source of injection water and surface preparation 16. Learning Outcomes (HWU Core Skills: Employability and Professional Career Readiness) Subject Mastery Understanding, Knowledge and Cognitive Skills Scholarship, Enquiry and Research (Research-Informed Learning) On completion of the course, the student should be able to: understand and appreciate the production system from reservoir to surface design suitable bottomhole completions systems understand the design principles of different perforation systems design an artificial lift system based on pumping and gas lifting techniques assess the degree of formation damage present in a formation design acidising and hydraulic fracturing treatments understand and be able to select appropriate methods to enable sand control understand the processes and equipment used in produced water handling 2/3 Form C4 Version 4.0 (2010/2011) Heriot-Watt University - Course Descriptor Template Personal Abilities Industrial, Commercial & Professional Practice Autonomy, Accountability & Working with Others Communication, Numeracy & ICT After completing this module, students will be able to: Appreciate the scale and complexity of the industry. Be aware of the social responsibility in protecting the environment and personnel in oil and gas operations. Understand the role of design codes. Understand the role of empiricism and approximation in design calculations. Develop appropriate skills in problem solving. Appreciate the practical application of chemical engineering fundamentals to equipment design. 17. Assessment Methods Method 18. Re-assessment Methods Duration of Exam Weighting (%) Synoptic courses? Method (if applicable) Examination Coursework 2 hours Duration of Exam Diet(s) (if applicable) 75% 25% None – qualifying course 19. Date and Version Date of Proposal 13-8-2012 Date of Approval by School Committee Date of Implementation Version Number 3/3 1.1