Test 2

advertisement

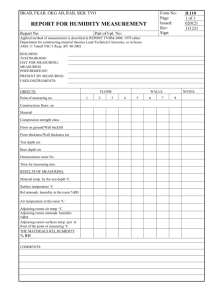

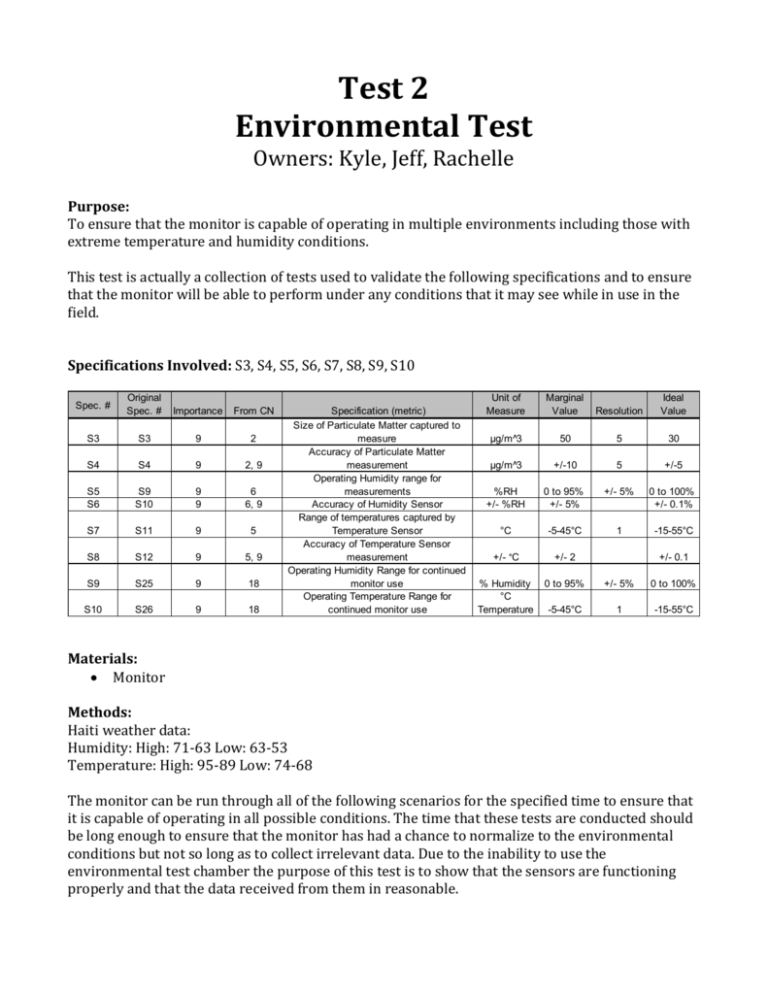

Test 2 Environmental Test Owners: Kyle, Jeff, Rachelle Purpose: To ensure that the monitor is capable of operating in multiple environments including those with extreme temperature and humidity conditions. This test is actually a collection of tests used to validate the following specifications and to ensure that the monitor will be able to perform under any conditions that it may see while in use in the field. Specifications Involved: S3, S4, S5, S6, S7, S8, S9, S10 Spec. # Original Spec. # Importance From CN S3 S3 9 2 S4 S4 9 2, 9 S5 S6 S9 S10 9 9 6 6, 9 S7 S11 9 5 S8 S12 9 5, 9 S9 S25 9 18 S10 S26 9 18 Specification (metric) Size of Particulate Matter captured to measure Accuracy of Particulate Matter measurement Operating Humidity range for measurements Accuracy of Humidity Sensor Range of temperatures captured by Temperature Sensor Accuracy of Temperature Sensor measurement Operating Humidity Range for continued monitor use Operating Temperature Range for continued monitor use Unit of Measure Marginal Value Resolution Ideal Value µg/m^3 50 5 30 µg/m^3 +/-10 5 +/-5 %RH +/- %RH 0 to 95% +/- 5% +/- 5% 0 to 100% +/- 0.1% °C -5-45°C 1 -15-55°C +/- °C +/- 2 % Humidity °C Temperature 0 to 95% +/- 5% 0 to 100% -5-45°C 1 -15-55°C +/- 0.1 Materials: Monitor Methods: Haiti weather data: Humidity: High: 71-63 Low: 63-53 Temperature: High: 95-89 Low: 74-68 The monitor can be run through all of the following scenarios for the specified time to ensure that it is capable of operating in all possible conditions. The time that these tests are conducted should be long enough to ensure that the monitor has had a chance to normalize to the environmental conditions but not so long as to collect irrelevant data. Due to the inability to use the environmental test chamber the purpose of this test is to show that the sensors are functioning properly and that the data received from them in reasonable. 1. Room Temp. a. Run Time: 10 minutes b. The sensor should be held at room temperature ~20°C(68°F) (in the EE SD Lab) to ensure that the monitor is initially functioning properly and that there are no unexpected fluctuations in the readings received from the monitor. c. This can be done using a 1 second measurement frequency if possible with available memory. 2. Low Temp. a. Run Time: 30 minutes b. Monitor should be held at a temperature of roughly -15°C(5°F) or lower to ensure lower operating temperature. c. This may be done by placing the monitor in a freezer or outside during the Rochester winter (weather permitting) to gather data. The monitor should however be protected from outside elements such as precipitation. 3. High Temp. a. Run Time: 30 minutes b. Monitor should be held above room temperature to ensure upper operating temperature. c. This test should validate both the sensor operation and the monitor’s electronics ability to operate at higher temperatures such as those that would be experience in Haiti. d. This may be done by bringing the monitor to somewhere such as the sauna in the RIT Field House where temperature is higher than room temperature. 4. High Humidity a. Run Time: 15 minutes b. Run monitor for an extended period of time in a high humidity environment to ensure that the monitor will record changes in humidity. Possible use of shower or going into an area such as the pool in the RIT Field House should be able to show correlation between high and low humidity. 5. Thermal-cycling a. Run Time: 20 minutes b. Monitor needs to go from warm to cold extreme repeatedly to ensure that gradual and rapid temperature changes will not impede the monitor’s ability to work. c. This can be done by repeatedly exiting and entering the Engineering building to take readings outside and inside. d. It should be timed the number of times that the monitor is cycled and the cycling should happen at regular intervals, either 1 minute or 30 seconds. 6. Particulate Matter a. Run Time 15 minutes b. Monitor should be placed in a very dusty environment to ensure that it is capable of operating when exposed to excessive particulate matter. c. Possible use of a candle or smoker’s exhale could be used. 7. After each test the monitor should be checked for physical damage before the data is extracted and then checked to ensure that it is valid.