TEXTILES SECTOR ENERGY EFFICIENCY PROGRAMME

advertisement

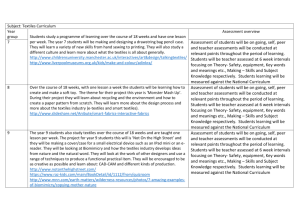

TEXTILES SECTOR ENERGY EFFICIENCY PROGRAMME Energy is vital to the textiles care industry. Electricity, gas, and sometimes coal, are used to drive energy intensive processes like washing, drying, pressing and hand finishing. It is estimated that energy is between 10% and 30% of a textiles care business’ overheads. Any improvements in the efficiency of use of energy in the sector will deliver financial savings as well as environmental improvement. The Textiles Sector Energy Efficiency Programme has been set up as a partnership between the Textile Care Federation, Textiles NZ and the Energy Efficiency and Conservation Authority (EECA). The programme was started in 2010 to provide practical advice and resources that help textiles care companies to work on energy efficiency. ENERGY MONITORING An important first step in improving energy efficiency is to monitor energy use. Simply recording energy consumed against production levels is a great place to start. The Textiles Sector Energy Efficiency Programme has developed an easy to use energy monitoring tool that enables textiles care companies to monitor monthly data on energy and production. [DOWNLOAD ENERGY MONITORING TOOL] SITE ASSESSMENTS The programme is offering practical onsite assessments of your energy use that will identify real opportunities to save energy and reduce energy bills. Each assessment is conducted by an expert engineer who quantifies energy efficiency opportunities for the site. A report is produced setting out all possible opportunities, and an action plan is developed to allow companies to prioritise changes. Companies are guided right the way through the process by a Textiles NZ coordinator. Assessments of textiles care companies under this programme have so far identified, on average, annual savings of close to 20% for each site. Some results are shown below: Textile care business Annual energy spend Annual energy savings identified Savings as % of energy spend 1 $55,982 $13,359 23.9% $838 $5,758 2.82 2 $48,970 $12,881 26.3% $960 $4,947 2.64 3 $54,211 $9,334 17.2% $412 $2,646 2.29 4 $101,138 $6,802 6.7% $600 $6,802 2.35 $260,301 $42,376 18.5% (avg) $2,810 $20,153 2.53 TOTAL Annual Annual savings savings with that payback in zero cost to less than 12 implement months Energy use index (kWh/kg) With funding from EECA, the Textiles Care Federation is offering companies a heavily subsidised energy assessment package that will help reduce energy bills. For more details please contact Simon Wilkinson, Textiles Energy Efficiency Programme Coordinator, on 021 944992. RESOURCES Quickstart Energy Efficiency Guidebook (Coming soon) Textiles Energy Efficiency Guidance Note 01 - Compressed Air [Download PDF] Compressed air systems are usually only between 10% - 15% efficient. As a rule of thumb, for every one unit of compressed work output, eight units of energy input are required at the air compressor. As a result, it is important to design and install the system correctly from the outset. Given the inefficient way these systems use energy, small reductions in compressed air use can often result in large energy savings. This best practice guidance note provides some simple tips and real-world examples of how to design and use compressed air systems more efficiently within textiles plants. Textiles Energy Efficiency Guidance Note 02 – Efficient Thermal Systems [Download PDF] The energy and maintenance cost of a boiler over its life often far exceeds the upfront capital cost. It is therefore important to design and install the system correctly from the outset. Given the large amount of energy these systems use, small improvements in energy efficiency can often result in large energy savings. This best practice guidance note provides some simple tips and real-world examples of how to design and use thermal systems more efficiently in a textiles plant. COMPANIES SAVE MORE THAN 20% ON ENERGY BILLS – NZ article from The Australian National Drycleaner & Launderer, July August September 2011 [Download PDF] TCF 2010 conference presentation on energy efficiency [Download PDF] LINKS Energy Efficiency and Conservation Authority http://www.eecabusiness.govt.nz/ EECA Textiles Care Case Studies Canterbury Laundry Service replaced two steam powered dryers with LPG direct fired dryers and cut its annual energy costs by $46,000. http://www.eeca.govt.nz/resource/canterbury-laundry-service-replaces-steam-powered-dryersand-saves Southern Lakes Laundries has installed a high-efficiency heat exchange unit for their main industrial washing machine that is delivery savings of up to $45,000 a year. http://www.eeca.govt.nz/resource/southern-lakes-laundries-heat-exchange-unit-delivers-savings After a half-day visit from an energy engineer to test and re-tune the burners on its boilers, Taylors Laundry Christchurch has found itself using 21,643 fewer litres of Light Fuel Oil (LFO) and saving $17,532 annually. http://www.eeca.govt.nz/resource/laundry-finds-over-17000-saving-simple-boiler-tune