Supporting Information

advertisement

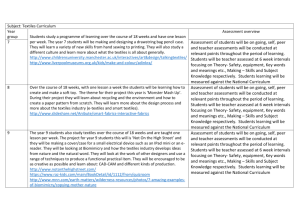

Supporting Information Stable superhydrophobic coatings from the thiol-ligand nanocrystals and their application in oil/water separation Jing Li,a Lei Shi,a Yu Chen,a Yabin Zhang,a,b Zhiguang Guo,*a,b a Bao-lian Su,c and Weimin Liua State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, People’s Republic of China, bMinistry of Education Key Laboratory for the Green Preparation and Application of Functional Materials, Hubei University, Wuhan 430062, People’s Republic of China, and cLaboratory of Inorganic Materials Chemistry, University of Namur, Namur B-5000, Belgium *Address correspondence to zguo@licp.cas.cn. 1 Table S1. pKsp value of different sulfides from Lange’s Handbook of Chemistry. pKsp FeS CoS NiS CuS Cu2S Ag2S 17.2 24.7 25.7 35.2 47.6 49.2 Figure S1. SEM images of the textiles coated with different nanocrystals, (a) FeO, (b, c) Fe2O3, (d) CoO, (e) NiO, (f) CuO from clean aqueous suspension, (g) CuO directly obtained from ethanol suspension, (h, i) Ag. 2 Figure S2. Water droplet standing on the textiles coated with CuO (a, c) before and (b, d) after octadecyl thiol modification. (a, b) nanocoatings from clean CuO aqueous suspensions, (c, d) nanocoatings directly from CuO nanoparticles suspensions in ethanol. Figure S3. Oil droplet such as hexadecane standing on the textiles coated with CuO after octadecyl thiol modification. Figure S4. Water droplet standing on the textile coated with Fe3O4. 3 0.30 Fe3O4 M (emu/g) 0.15 0.00 -0.15 -0.30 -10000 -5000 0 H (Oe) 5000 10000 Figure S5. The magnetic hysteresis loop of as-prepared Fe3O4. Figure S6. A photo showing that the textile coated with Fe3O4 is magnetic when a magnet is close to it. 4 Co 2p3/2 780.8 Co 2p1/2 796.5 775 780 785 790 795 800 805 810 Binding Energy (eV) Figure S7. XPS spectrum of as-prepared textiles coated with CoO. 856.0 Ni 2p3/2 873.4 861.4 Ni 2p1/2 879.4 855 860 865 870 875 880 Binding Energy (eV) Figure S8 XPS spectrum of as-prepared textiles coated with NiO. 5 Cu 2p3/2 932.3 Cu 2p1/2 952.1 930 935 940 945 950 955 Binding Energy (eV) Figure S9. XPS spectrum of as-prepared textiles coated with CuO. Ag 3d5/2 367.8 Ag 3d3/2 373.8 366 368 370 372 374 376 Binding Energy (eV) Figure S10. XPS spectrum of as-prepared textiles coated with Ag. 6 Figure S11. Water droplet standing on the textiles coated with TiO2. Figure S12. Water droplet at different temperatures standing on the textiles. 7 Figure S13. (a) As-prepared superhydrophobic textiles on water surface. (b) Superhydrophobic textiles in 0.4% SDBS aqueous solution. (c) Superhydrophobic textiles in hexane. Figure S14. The effect of 0.04% SDBS aqueous washing on the wettability of as-prepared textiles. 8 Figure S15. The effect of 0.4% SDBS aqueous washing on the wettability of as-prepared textiles. Figure S16. The effect of 0.4% CTAB aqueous washing on the wettability of as-prepared textiles. 9 Figure S17. The effect of ultrasonic treatment in nonpolar solvents on the wettability of as-prepared textiles. 180 CA (Deg) 160 140 120 100 0 1 2 3 4 5 6 7 8 9 10 11 Repeated time Figure S18. The contact angle of water on the superhydrophobic textiles after each oil-water separation. 10 Figure S19. Schematic illustration of surface perfluorination on the textiles. Figure S20. Water (blue colored by methylene blue) and oil droplet standing on the textiles after surface perfluorination. 11