View

advertisement

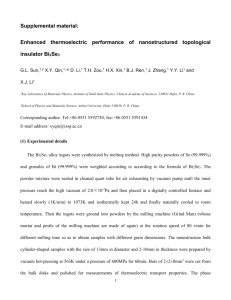

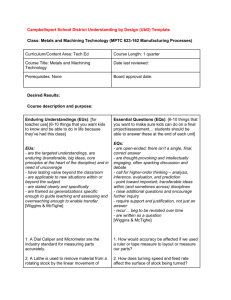

Evolution and growth of the LTP MnBi Phase in Mn-Bi system V.V.Ramakrishna, S.Kavita*, D.Siva Prahasam, D. Prabhu, Ravi Gautam and R.Gopalan International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Chennai600113, India * Corresponding author’s e-mail: skavita@arci.res.in, Tel.: +91-44-66632816; Fax: +91-66632802 Abstract The paper reports the effect of ball milling on the evolution of the LTP MnBi phase content in Mn52Bi4 alloy. Coercivity was observed to increase with milling and Hc of ~1T was achieved in the sample milled for 5 hours. Keywords: Intermetallics, Mn-Bi alloy, coercivity, ball milling, magnetic properties. Introduction MnBi has evoked substantial interest in the search for rare earth free permanenet magnet owing to its good intrinsic properties. The coercivity of LTP MnBi phase increases with temperature and is much higher than the coercivity of Nd-Fe-B at higher temperatures [1].Therefore; MnBi has high potential as a permanent magnet at high temperature. Numerous attempts have been made to obtain single-phase MnBi, but the segregation of Mn and Bi phase could not be avoided [2]. Here we report the effect of milling on the evolution of LTP MnBi phase and its magnetic properties in arc melted Mn52Bi48 alloy the relative intensity of MnBi peak ( 2θ = 28.13 o) compared to Bi peak (2θ = 27.26 o). The increase in the relative intensity of the MnBi phase suggests that the energy derived from ball milling acts a driving force for the alloying of unreacted elemental Mn and Bi to form LTP MnBi. On further milling the intensity of Bi phase increases suggesting decomposition of the already formed LTP MnBi phase. SEM micrographs shows (fig1 (b)) a clear reduction in particle size with milling. Fig. 1(c) shows the increase in coercivity with milling It is found that the coercivity increases to 1T after milling for 5hrs. The increase in coercivity could be due to the decrease in particle size as Hc is inversely proportional to the particle size above the single domain size which is 500 nm for MnBi. The magnetization in MnBi system strongly depends on atomic arrangement of Mn and Bi, in the lattice. The decrease in magnetization (fig. 1 (d)) inspite of increasing LTP MnBi phase suggests the rearrangement of Mn and Bi atoms within the MnBi lattice during milling. Experimental An alloy ingot with a nominal composition of Mn52Bi 48 was prepared by arc melting the constituent elements in Ar atmosphere. The melted ingot was vacuum sealed and subjected to annealing for 24hrs at 3000C to obtain LTP MnBi phase. Fritisch Ball mill with a ball to powder ratio of 1:10 and rotation speed of 60rpm. Stainless steel vials and balls (10mm) were used for milling. The structural characterization at each stage of milling has been done using with CuKα (=1.54059Å) radiation in a PANalytical (X’pert PRO). The magnetic properties at each stage of milling were done by using Microsense Easy VSM Model EV9. Particle size variation with milling was observed using a scanning electron microscopy (SEM) (Quanta 3D FEG). Results and Discussion Figure 1(a) shows the XRD pattern of the alloy annealed at 3000C for 24hrs and subsequently ball milled for 5hr. The annealed alloy ingot shows elemental Bi as a major peak and LTP MnBi peaks as minor phase. With the increase in milling time, one can clearly observe from the XRD pattern an enhancement in the volume fraction of the LTP MnBi phase at the expense of Bi phase which is reflected in the increase in Fig. 1: (a) XRD of Mn-Bi with milling (b) SEM image of as-crushed and 5 hr milled (c) variation of coercivity(d) magnetization with milling. References [1] X .Guo, X.Chen, Z.Altounian and J.O .Str¨omOlsen Phys. Rev. B 46, 14 578 (1992) [2] H.Yoshida, T.Shima, T.Takahashi and H.Fujimori Mater. Trans. JIM 40, 455(1999)