Metals and Machining - Campbellsport Public Schools

advertisement

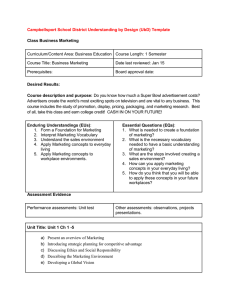

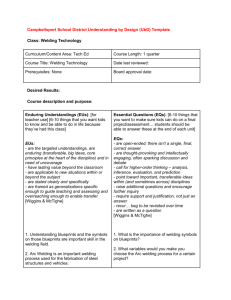

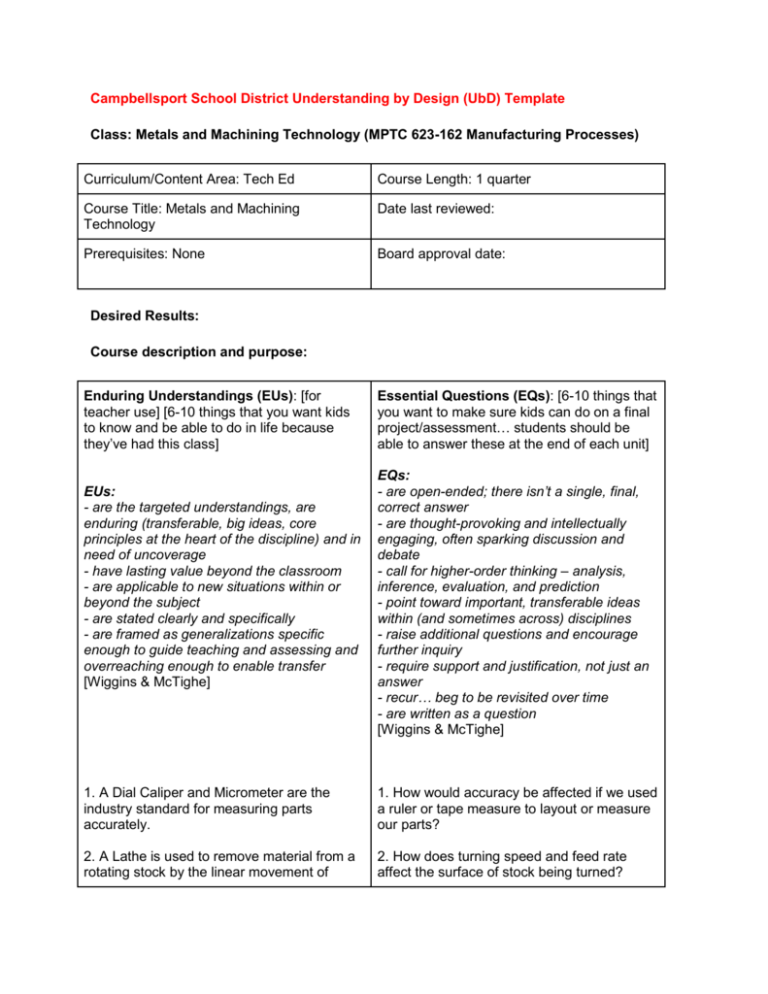

Campbellsport School District Understanding by Design (UbD) Template Class: Metals and Machining Technology (MPTC 623-162 Manufacturing Processes) Curriculum/Content Area: Tech Ed Course Length: 1 quarter Course Title: Metals and Machining Technology Date last reviewed: Prerequisites: None Board approval date: Desired Results: Course description and purpose: Enduring Understandings (EUs): [for teacher use] [6-10 things that you want kids to know and be able to do in life because they’ve had this class] EUs: - are the targeted understandings, are enduring (transferable, big ideas, core principles at the heart of the discipline) and in need of uncoverage - have lasting value beyond the classroom - are applicable to new situations within or beyond the subject - are stated clearly and specifically - are framed as generalizations specific enough to guide teaching and assessing and overreaching enough to enable transfer [Wiggins & McTighe] Essential Questions (EQs): [6-10 things that you want to make sure kids can do on a final project/assessment… students should be able to answer these at the end of each unit] EQs: - are open-ended; there isn’t a single, final, correct answer - are thought-provoking and intellectually engaging, often sparking discussion and debate - call for higher-order thinking – analysis, inference, evaluation, and prediction - point toward important, transferable ideas within (and sometimes across) disciplines - raise additional questions and encourage further inquiry - require support and justification, not just an answer - recur… beg to be revisited over time - are written as a question [Wiggins & McTighe] 1. A Dial Caliper and Micrometer are the industry standard for measuring parts accurately. 1. How would accuracy be affected if we used a ruler or tape measure to layout or measure our parts? 2. A Lathe is used to remove material from a rotating stock by the linear movement of 2. How does turning speed and feed rate affect the surface of stock being turned? cutting tools and bits. 3. A Milling Machine is used to remove material off a surface by the use of a milling cutter. 4. Welding is a process of permanently joining two types of metal together through the use of high heat. 5. Heat treating is the process of heating and cooling metal to change its physical properties. 3. How does cutting speed and feed rate affect the surface of stock being milled? 4. Why must you tack both ends of a weld before running a bead? 5. Why would you want to heat treat the end of a metal chisel? 6. How does safety in the Metals Shop translate to safety outside of school? 6. Metal Shop safety and proper usage of machines is the most important topic in Metals and Maching. Assessment Evidence Performance assessments: Other assessments: Measuring and Layout A. Print Reading B. Symbols and Meaning C. Dial Calipers D. Micrometer Standards (CCSS, Next Generation Science, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Lathe Techniques A. Turning B. Tapering C. Knurling D. Speeds and Feed Rate Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Milling and Machining Techniques A. Surface Milling B. CNC Milling C. Speeds D. Feed Rate Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Welding and Fabrication Techniques A. Arc or Stick B. MIG C. TIG D. Plasma and Torch Cutting Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: Forging and Heat Treating Techniques A. Annealing B. Case Hardening C. Tempering D. Quenching Standards (CCSS, Next Generation, ACT College and Career Readiness, etc.) Learning Targets Addressed [“I can” statements (focus on skill-based vs. contentbased)]: