Supplementary_data_JAN15

advertisement

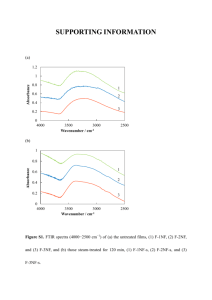

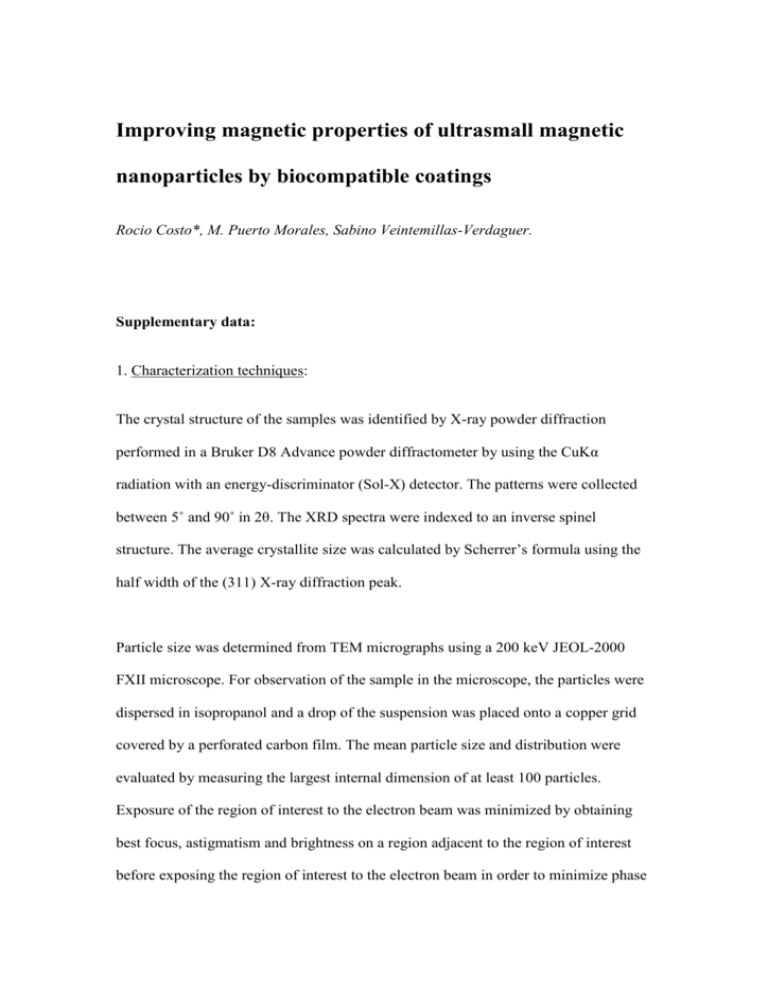

Improving magnetic properties of ultrasmall magnetic nanoparticles by biocompatible coatings Rocio Costo*, M. Puerto Morales, Sabino Veintemillas-Verdaguer. Supplementary data: 1. Characterization techniques: The crystal structure of the samples was identified by X-ray powder diffraction performed in a Bruker D8 Advance powder diffractometer by using the CuKα radiation with an energy-discriminator (Sol-X) detector. The patterns were collected between 5˚ and 90˚ in 2θ. The XRD spectra were indexed to an inverse spinel structure. The average crystallite size was calculated by Scherrer’s formula using the half width of the (311) X-ray diffraction peak. Particle size was determined from TEM micrographs using a 200 keV JEOL-2000 FXII microscope. For observation of the sample in the microscope, the particles were dispersed in isopropanol and a drop of the suspension was placed onto a copper grid covered by a perforated carbon film. The mean particle size and distribution were evaluated by measuring the largest internal dimension of at least 100 particles. Exposure of the region of interest to the electron beam was minimized by obtaining best focus, astigmatism and brightness on a region adjacent to the region of interest before exposing the region of interest to the electron beam in order to minimize phase changes and sample damage induced by the microscope electron beam. Subnanometric structural characterization (subnanometric changes in particle size or structure as stacking faults, dislocations or twin boundaries) was not performed by HR-TEM for the same reason. Infrared spectra of the samples diluted in 2% KBr were recorded between 4000 and 400 cm-1 in a Bruker IFS 66V-S spectrometer and a Nicolet FT-IR 20SXC. The magnetic properties of the samples were recorded in a MagLabVSM vibrating sample magnetometer from Oxford Instrument. For the measurement of powders, the samples were dried in an inox-coated oven at 50˚C 24h. Afterwards, the samples were accurately weighed and fitted into the sample holder. To minimize interactions in the liquid samples, the dispersions were prepared at low concentrations (0.25 wt%). To avoid nanoparticle aggregation due to the VSM magnetic field, liquid samples were always measured in the frozen state. One hundred microliters of the sample were placed in the sample holder and immersed in liquid nitrogen before being placed in the VSM. The temperature was always kept under 250 K. Temperature-dependent zero field cooling (ZFC) and field cooling (FC) magnetization measurements were taken by initially cooling the samples to 5 K in the zero and 200 Oe fields, respectively. Then, magnetization was measured during the heating cycle (3 K · min1 ) from 5 to 250 K under a 200 Oe field. Hysteresis loops of the powder samples were measured at RT and at 5 K at a rate of 5 kOe·min-1. Saturation magnetization was evaluated by extrapolating to an infinite field the experimental data obtained in the high field range where magnetization increases linearly with H which can be approximated to a 1/H law. Exchange anisotropy studies were undertaken by freezing the sample to 5 K in a 50 kOe field. Afterwards, hysteresis loops were carried out at 5 kOe·min-1. The magnitude of the loop shift (HS) and coercivity (Hc) were calculated by HS= - (H0+ + H0-)/2 and Hc= (H0+ - H0-)/2, respectively. Simultaneous thermogravimetric (TG) and differential thermal analysis (DTA) analysis were performed on a Seiko TG/DTA 320U thermobalance. Samples were heated from room temperature to 900˚C at 10˚C/min under an air flow of 100 ml/min. Iron determination was carried out in an Inductively Coupled Plasma – Optical Emission Spectrometry (ICP-OES) apparatus, OPTIME 2100DV from Perkin Elmer. Determination of the carbon content was carried out in a Perkin Elmer 2400 CHNS/O Series II analyzer. A Zetasizer nano ZS by Malvern Instruments was used to determine both the hydrodynamic size and Z-potential. This device is equipped with a He‐Ne laser (4 mW, 633 nm), an automatic laser attenuator (transmission from 100% to 0.0003%) and an avalanche photodiode detector. The mean hydrodynamic diameter of the aggregates was measured thanks to non invasive back scatter (NIBS) technology and dynamic light scattering (DLS) which allow measure sizes from 0.6 nm to 6 μm. To minimize the effect of multiple scattering, measurements at three different sample concentrations were performed. The result with the higher count number and the best position was selected as correct. A log‐normal distribution function was used to fit the size data obtained. It is worthy to mention that although the fundamental size distribution generated by DLS is an intensity distribution, this can be converted to a volume distribution using the refraction index (2.42 for maghemite) and the Mie theory. This volume distribution can be further converted to a number distribution; however, number distributions are of limited use as small errors in gathering data could lead to huge errors in distribution by number. In most of the experiments of this work, the hydrodynamic size distribution is measured in terms of volume instead of intensity. The use of the volume mode is specially appropriated in case of two or more different size populations in the sample. In these cases when we measure in intensity mode, we are overestimating the contribution of the large particles. This is because large particles scatter much more light than small particles (the intensity of scattering of a particle is proportional to the sixth power of its diameter ‐ from Rayleigh’s approximation). 2. X-ray diffraction analysis: Intensity (a.u.) (311) UNCOATED SAMPLE (440) (400) (511) 10 20 30 40 50 60 70 80 90 2CuK Figure S1: XRD diffractogram of the iron oxide nanoparticles synthesized by laser pyrolysis before the coating process. The peaks have been indexed to a spinel structure, -Fe2O3 JPCDS file Nº 39-1346 3. FTIR Spectra: PAA 2,5 Absorbance Units Absorbance Units 2,5 2,0 1,5 1,0 0,5 3500 3000 2500 2000 1500 1000 PAA 2,0 1,5 1,0 0,5 2000 500 -1 PAMIDRONIC 1,4 Absorbance Units Absorbance Units 500 Wavenumber (cm ) 1,2 1,0 0,8 0,6 0,4 PAMIDRONIC 1,2 1,0 0,8 0,6 0,4 0,2 2000 0,2 3500 3000 2500 2000 1500 1000 500 1500 CM-DEXTRAN CM-DEXTRAN Absorbance Units 1,0 0,8 0,6 0,4 0,2 3000 2500 500 Wavenumber (cm ) Wavenumber (cm ) 3500 1000 -1 -1 Absorbance Units 1000 -1 Wavenumber (cm ) 1,4 1500 2000 1500 1000 500 1,0 0,8 0,6 0,4 0,2 2000 -1 Wavenumber (cm ) 1500 1000 500 -1 Wavenumber (cm ) Figure S2: FTIR spectra of the coating molecules recorded between 3600 and 300 cm-1 (left) and between 2000 and 300 cm-1 (right).