(2) Preparation of sample M2: The only difference between sample

advertisement

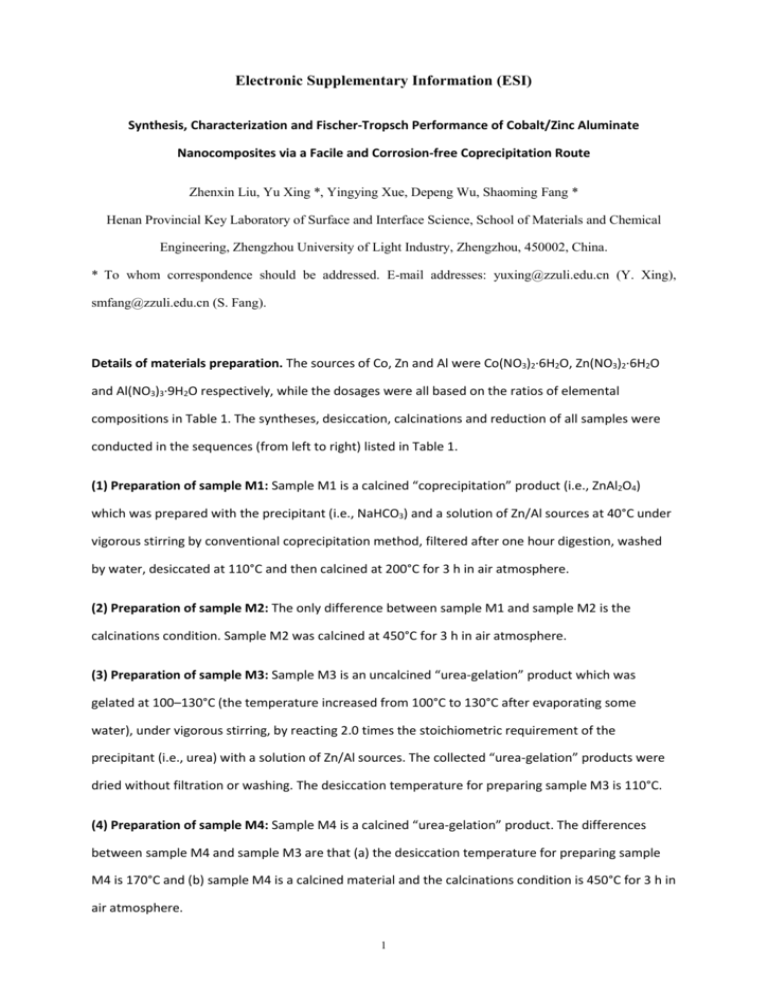

Electronic Supplementary Information (ESI) Synthesis, Characterization and Fischer-Tropsch Performance of Cobalt/Zinc Aluminate Nanocomposites via a Facile and Corrosion-free Coprecipitation Route Zhenxin Liu, Yu Xing *, Yingying Xue, Depeng Wu, Shaoming Fang * Henan Provincial Key Laboratory of Surface and Interface Science, School of Materials and Chemical Engineering, Zhengzhou University of Light Industry, Zhengzhou, 450002, China. * To whom correspondence should be addressed. E-mail addresses: yuxing@zzuli.edu.cn (Y. Xing), smfang@zzuli.edu.cn (S. Fang). Details of materials preparation. The sources of Co, Zn and Al were Co(NO3)2·6H2O, Zn(NO3)2·6H2O and Al(NO3)3·9H2O respectively, while the dosages were all based on the ratios of elemental compositions in Table 1. The syntheses, desiccation, calcinations and reduction of all samples were conducted in the sequences (from left to right) listed in Table 1. (1) Preparation of sample M1: Sample M1 is a calcined “coprecipitation” product (i.e., ZnAl2O4) which was prepared with the precipitant (i.e., NaHCO3) and a solution of Zn/Al sources at 40°C under vigorous stirring by conventional coprecipitation method, filtered after one hour digestion, washed by water, desiccated at 110°C and then calcined at 200°C for 3 h in air atmosphere. (2) Preparation of sample M2: The only difference between sample M1 and sample M2 is the calcinations condition. Sample M2 was calcined at 450°C for 3 h in air atmosphere. (3) Preparation of sample M3: Sample M3 is an uncalcined “urea-gelation” product which was gelated at 100–130°C (the temperature increased from 100°C to 130°C after evaporating some water), under vigorous stirring, by reacting 2.0 times the stoichiometric requirement of the precipitant (i.e., urea) with a solution of Zn/Al sources. The collected “urea-gelation” products were dried without filtration or washing. The desiccation temperature for preparing sample M3 is 110°C. (4) Preparation of sample M4: Sample M4 is a calcined “urea-gelation” product. The differences between sample M4 and sample M3 are that (a) the desiccation temperature for preparing sample M4 is 170°C and (b) sample M4 is a calcined material and the calcinations condition is 450°C for 3 h in air atmosphere. 1 (5) Information about sample M5: Sample M5 is a commercial γ-Al2O3, Catalox SBA-150 with a BET specific surface area of 150 m2/g, which was supplied by Sasol North America. (6) Preparation of sample M6: Sample M6 is prepared by calcining sample M5 at 550°C for 4 h in air atmosphere. (7) Preparation of sample M7: Sample M7 is prepared by impregnating sample M5 with a Co(NO3)2·6H2O solution using an incipient wetness method. The desiccation temperature for preparing sample M7 is 110°C. (8) Preparation of sample M8: Sample M8 was prepared by reducing sample M7 in 50% H2/50% He with seven temperature stages (200°C/250°C/300°C/350°C/400°C/450°C, a soak time of 2 h for each of the six stages, plus a final stage of 550°C for 4 h). (9) Preparation of sample M9: Sample M9 is a reduced “coprecipitation” product which was prepared with the precipitant (i.e., NaHCO3) and a solution of Co/Al sources at 40°C under vigorous stirring by conventional coprecipitation method, filtered after one hour digestion, washed by water, desiccated at 110°C and then reduced in 50% H2/50% He with above mentioned seven temperature stages (the final stage is 550°C/4 h). (10) Preparation of sample M10: Sample M10 is an unreduced “coprecipitation” product which was prepared with the precipitant (i.e., NaHCO3) and a solution of Co/Zn/Al sources at 40°C under vigorous stirring by conventional coprecipitation method, filtered after one hour digestion, washed by water and then desiccated at 110°C. (11) Preparation of sample M11: Sample M11 was prepared by reducing sample M10 in 50% H2/50% He with above mentioned seven temperature stages (the final stage is 550°C/4 h). (12) Preparation of sample M12: Sample M12 is a reduced “urea-gelation” product which was gelated at 100–130°C (the temperature increased from 100°C to 130°C after evaporating some water), under vigorous stirring, by reacting 2.0 times the stoichiometric requirement of the precipitant (i.e., urea) with a solution of Co/Zn/Al sources. The collected “urea-gelation” products were dried without filtration or washing. The desiccation temperature for preparing sample M12 is 170°C. The reducing condition for preparing sample M12 is the same as above mentioned seven temperature stages (the final stage is 550°C/4 h). 2 (13) Preparation of sample M13: Sample M13 is prepared by impregnating sample M2 with a Co(NO3)2·6H2O solution using an incipient wetness method. The desiccation temperature for preparing sample M13 is 110°C. The reducing condition for preparing sample M13 is the same as above mentioned seven temperature stages (the final stage is 500°C/4 h). (14) Preparation of sample M14: Sample M14 is prepared by impregnating sample M4 with a Co(NO3)2·6H2O solution. The desiccation temperature for preparing sample M14 is 110°C. The reducing condition for preparing sample M14 is the same as above mentioned seven temperature stages (the final stage is 500°C/4 h). Co(NO3)2 + γ-Al2O3 (inert) → CoOx + γ-Al2O3 (inert) → Co0/γ-Al2O3 (1) (sample M8) Co/Al precipitate → CoOx + Al2O3 (active) → CoAl2O4/trace Co0/Al2O3 (2) (sample M9) Zn/Al precipitate → ZnO (active) + Al2O3 (active) → ZnAl2O4 (3) (sample M1 or M2) Co/Zn/Al precipitate → CoOx + ZnO (active) + Al2O3 (active) → CoOx + ZnAl2O4 → Co0/ZnAl2O4 (4) (sample M11) Supplementary Material Scheme S1. Possible main chemical reactions involved in the experimental work during the calcinations in air atmosphere (equation 3) or the reduction in 50% H2/50% He (equations 1, 2 and 4) Supplementary Material Table S1. Texture features of synthesized ZnAl2O4 supports code M2 M4 a surface area a /(m2/g) 146.91 139.33 pore volume b Vpore /(cm3/g) 0.168 0.193 average pore diameter c /nm 4.6 5.5 BET specific surface area. b Single point total pore volume of pores smaller than 165.7 nm diameter at P/P0 = 0.98828. c Average pore diameter (4V/A by BET). 3 Supplementary Material Table S2. Rough quantitative analysis of surface elements by EDS data.* code Co (K) 0 0 4.5 8.8 12.1 15.1 49.7 M2 M4 M8 M11 M12 M13 M14 O (K) 47.8 51.7 48.8 46.9 47.7 41.1 22.9 atom % Zn (L) Al (K) 17.4 34.8 12.6 35.7 0 45.3 12.5 31.8 12.1 28.1 14.5 29.3 14.7 12.7 Na (K) 0 0 1.4 0 0 0 0 Total 100 100 100 100 100 100 100 atomic Al/Zn 2.0 2.8 ∞ 2.5 2.3 2.0 0.9 wt % Co (K) 0 0 11.5 17.6 23.5 27.0 63.6 * Gold was sprayed over the surface of samples to enhance the electrical conductivity and thus the image contrast of the samples. The EDS data of gold (Au) and carbon (C) were not included in this data sheet. The source of carbon is probably due to remaining carbonates or/and adventitious carbon on the surface of the nanocomposites. 100 80 % Weight a 60 40 b 20 0 0 100 200 300 400 500 600 700 800 900 Temperature (°C) Supplementary Material Figure S1. Thermogravimetry (TGA) curves of two as-synthesized materials. (a) sample M10, (b) sample M3. 4 5 6 Supplementary Material Figure S2. Energy dispersive X-ray spectra (EDS Spectra) of the materials. Supplementary Material Tables S1-S2 and Supplementary Material Figures S1-S2 were described in the article. 7