Oral Fast Disintegrating Tablet - International Journal of Advances in

advertisement

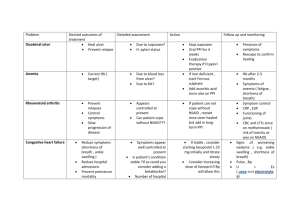

FORMULATION AND IN-VITRO EVALUATION OF ORAL FAST DISINTEGRATING TABLET OF LISINOPRIL MALEATE Hira Ijaz*1, Ayesha Sethi 1, Junaid Qureshi 1, Naveed Anwar2, Mehmood Ahmad3, Farzana Chaudry4 1 College of Pharmacy, Govt. College University Faisalabad, Pakistan,2Faisalabad Intitute of Cardiology, Faisalabad, Pakistan. 3Dean, Faculty of Pharmacy & Alternative Medicine, The Islamia University Bahawalpur, Pakistan, 4Director university of veterinary and animal sciences, Lahore, Pakistan. * Corresponding Author’s Phone: +92-3457808041,Email:pharmacisthira@gmail.com Abstract The objective of the study was to design fast dissolving tablets of lisinopril maleate were prepared using different superdisintegrants. Superdisintegrants like SSG and CC-Na were used for preparation of oral dispersible lisinopril maleate tablet by direct compression method. Polymers were used alone or in combination for preparation of oral dispersible tablet. FDTs were evaluated for physicochemical properties and in vitro dissolution. Effect of disintegrant on disintegration behaviour of tablet in 0.1N HCl was evaluated. The drug release from FDTs increased with increasing concentration of superdisintegrants and was found to be highest with formulations containing combination of SSG and CC-Na. However Formulation L1, L2, L3, L4, L5, L6, L7 and L8 showed 76.38%, 72.2%, 63.8%, 84.7%, 76.3% 63.8%, 91.6% and 81.9% drug release after 10min. Formulation L7 a combination of 2% SSG and 3% CC-Na was selected. Key words: Lisinopril maleate, sodium starch glycolate, cross carmellose sodium, FDTs, Direct compression 1 basedydisintegrants1. 1. Introduction Orally administered dosage forms Fast disintegrating tablets (FDTs) have received e.g. tablets, capsules are ever-increasing convenient for many drugs but demand during the last decade, they are challenging to formulate and the field has become a rapidly growing area pharmaceutical in the industry. Upon if the active substance has poor dissolution or low bioavailability. Polymer introduction into the mouth, these and the mouth in the absence of water administration for of of several formulations and thus offer an alternate form of in oral medication, which provide FDT patients with a more convenient means of taking their medication7. and Lisinopril is lysine derivative of technologieslhavegdevelopedgntoj enalapril8,9. achievemfastkdissolution/dispersi technologies enzyme. based vasoconstrictor. the FDT properties, such as spray- and use peptidyl which inhibits Angiotensin II causes the release of aldosterone treatment, of is angiotensin II which is potent well as approaches to enhancing sintering, competitive conversion of angiotensin I into sublimation, and compaction, as moisture is ACE dipeptidase onjlyophilization,dmolding, drying, It inhibitor of angiotensin converting on of tablets in the oral cavity. FDT of overcome all the above problems technologies. Various masking mouth or orodispersible tablets popularity and usefulness of the development taste The rapidly disintegrating tablet in active resulted the bitter taste drugs2,3,4,5,6. easy pharmaceutical ingredients. The formulation enables formulation of mouth dissolving tablets dissolve or disintegrate in additional coating from sugar2 adrenal cortex. It also decreases the vesopressor activity Aspartam were gifted by Unexo 10,11 Labs Pvt Ltd Lahore. . Formula of lisinopril is 2.1 Methodology C21H31N3O5, 2H2O. Lisinopril is angiotensin 2.1.1 Preparation of Lisinopril converting enzyme maleate oral dispersible tablet. inhibitor. Lisinopril is 98.5 101.5% (anhydrous substance). Lisinopril and microcrystalline Lisinopril belongs to BCS Class cellulose III drug (High solubility and low disintegrant in pestle and mortar permeability). Lisinopril maleate for is through white or almost white, 15 were minutes, sieve mixed then with passed no 60.Then crystalline powder. It is soluble in erythrosine red was added and water, compressed using 6mm punch. sparingly soluble in The blend was mixed with methanol, practically insoluble in acetone and in anhydrous ethanol. cab-O-sil and magnesium stearate. 12 2.2 Pre-compression parameter 2. Materials and method Bulk density Lisinopril maleate (ACE inhibitor) Tapped density was Haussner’s Ratio gifted Therapeutics Sodium by Razee Pvt starch Crosscarmellose Ltd & Carr’s Index Lahore. glycolate and sodium were Angle of repose 2.2.1 Bulk density gifted by Werrick pharmaceuticals Bulk density was evaluated by Pvt Ltd. Islamabad. Cab-O-sil, separately Magnesiumhstreate, Microcrystalline cellulose weighting lisinopril maleate formulations. Separately and transferred 3 pre-sieved powder blend in to 100ml volumetric Haussner’s Ratio = Tapped cylinder and measured the initial density / Bulk density volume of powder. Then bulk Carr’s Index and Haussner’s Ratio density was calculated 13, 14, 15. are simple and fast method to detect flow properties of powder.16 Bulk density = Mass of granules / Volume of granules 2.2.5 Angle of Repose 2.2.2 Tapped density Angle of repose for blend of Tapped density was determined by formulations of lisinopril maleate tapping the volumetric cylinder for was determined by using fixed specified period of time initially funnel method.17,18 and measure tap density by using tan θ = h / r formula. 13,14,15 h= Height of heap Tapped density = Mass of r = Radius of heap granules / Tapped volume of 𝜃 = Angle of repose granules 2.3 Post compression 2.2.3 Carr’s Index parameters of lisinopril maleate Compressibility was found by Physical properties using formula. 16 Thickness Diameter C.I = Tapped density – Bulk Weight variation density / Tapped density Hardness test Friability test 2.2.4 Haussner’s Ratio Drug content uniformity Wetting time It is the number related to Disintegration time flowability of granules. 16 4 In-vitro dissolution studies Average weight of all tablets was 2.3.1 Post compression calculated. Weight individual parameters tablets. Then compared the individual weight of tablet with 2.3.1.1 Physical Appearance average weight and calculated weight variation.22,23 Tablets were evaluated for shape, size and colour. 2.3.1.5 Friability 2.3.1.2 Thickness Randomly pre-weighted and Ten tablets were taken and dusting 20 tablets were transferred thickness was determined by using to plastic chamber of friabilator. digital vernier caliper. Friabilator was operated at 25rpm for 4min and tablets were dropped 2.3.1.3 Hardness at distance of 6 inches with each Hardness is defined as force revolution. Friabiliator was required for breaking the tablet. revolved for 100 revolutions, after Hardness was determined by using which tablets were again dusted hardness tester. Ten tablets were and weighted. Calculate %age taken from each formulation and weight loss. Percentage friability hardness was determined using was calculated by using formula.24 hardness tester. Crushing strength % age friability = Initial weight – is measure in Kg/cm2. Crushing Final weight × 100 / Initial weight strength is average pressure apply to break tablet.19,20,21 2.3.1.6 Drug content uniformity 2.3.1.4 Weight variation Six tablets were grinded and weighted in pestle and mortar. Twenty tablets were accurately Transfer 50 mg drug to 50ml of weighted on analytical balance. 0.1 N HCl to prepare stock 5 solution (1000mcg/ml). Then operated for specified period of 10ml of stock solution was drawn time using at 370C. Then time and diluted with 100ml of 0.1 N required by tablet to disintegrate HCl (100mcg/ml). At the end 2ml was calculated calculated.26,27,28 from stock solution was drawn 2.3.1.9 In-vitro drug release and diluted to 10ml. Check studies of Lisinopril maleate absorbance at 215nm by using In-vitro UV- Visible spectrophotometer at 215nm.10 drug release studies of lisinopril tablets were carried out by using USP 2.3.1.7 Wetting time Type II Dissolution Apparatus. Five Petri dishes were taken and Dissolution test was carried out by put circular tissue papers of 10cm using diameter in them. In petri dishes (pH=1.2) at 37±0.20C at 50 rpm put 10ml of water having for lisinopril maleate. Aliquot of temperature of 37±0.5 0C contain solution was drawn at 10, 15, 20, a water soluble dye. Put six tablets 30, 40, 50 and 60 min. Sample from each formulation on the was filtered through whatmann surface of tissue paper in each filter and then diluted with the petri dish and time required for dissolution medium. Aliquot of water to reach the upper surface of solution withdrawn was replaced tablet is noted as wetting time. 25 with fresh dissolution medium to 900ml of 0.1N HCl maintain constant volume. Check absorbance spectrometrically at λ 2.3.1.8 Disintegration test max Disintegration time was evaluated 215nm maleate.21,25,29,30 by using disintegration apparatus. One tablet was placed in each six baskets, disk was inserted and 6 for lisinopril DrugRelease= 3.2Post compression parameters (absorbance of the sample) × of lisinopril maleate 100/ 3.2.1 General Appearance (absorbance of the standard) Lisinopril maleate Tablets 3. Results Tablets were evaluated for size, 3.1 Pre-compression parameters shape, color variation, unwanted of lisinopril maleate foreign particles, damage etc. Blend of lisinopril maleate tablets were found to be of good formulations were evaluated for texture and free of any bulk density, tapped density, inadequacy. hausner’s ratio, cars index. Results 3.2.2 Thickness and Diameter of bulk density are shown in table test for lisinopril maleate tablets 4.1. Bulk density was within the range of 0.21-0.26. Tapped 20 Tablets from each batch were density was in range of 0.26-0.32. selected randomly and tested for Hausner’s ratio was in range of thickness and diameter with the 1.22-1.24 Lisinopril maleate help of Vernier calipers and it was showed excellent flow properties. found that tablets from each batch Carr’s index was in between 18- were of uniform dimensions as 19. Angle of repose was found by shown in table using fixed funnel method. Results 3.2.3Uniformity of Mass of were in acceptable range, which lisinopril maleateTablet 0. fall in between 20-23 This showed powder has excellent flow 20 tablets were randomly selected properties. from each batch, weighed individually on digital balance and average mass was calculated 7 6 and 7 showed that formulation L1, L2, L3, L4, L5, L6, L7 and L8 3.2.4 Friability Test of lisinopril showed 76.38%, 72.2%, 63.8%, maleate 84.7%, 76.3% 63.8%, 91.6% and Twenty tablets were taken from 81.9% drug release. In-vitro each formulation. All the tablets dissolution studies of formulation were weighted accurately. Tablets L7 showed that 100% drug release were placed in the friabilator. after 30min. Friabilator was rotated at 25rpm Formulation L1 containing 5% for 4min. After removing tablets SSG showed 98.6% drug release were de- dusted and weighted after 40min which was due to again. Then Calculated the %age enormous swelling followed by weight loss. All formulations rapid disintegration. As showed less than 1% weight loss, concentration of SSG decreased to which are within range. 4% and 3% drug disintegration Oral dispersible lisinopril was occured after 50min and 60min prepared using different Formulations L4, L5, L6 concentration of containing 5%, 3% and 2% CC- superdisintegrants like SSG and Na showed 98.6% drug release CC-sodium. Tablet thickness, with in 40min, 50min and 60min diameter and hardness found to be respectively which may be due to in acceptable range. Drug contents rapid water uptake and strong were in between 93.9-99.1%. In- swelling of disintegrant. But vitro disintegration time fall during formulation of lisinopril between 22-52min. Formulation layer 5% and 4% SSG and CC-Na L7 containing 3% CC-sodium and showed 98.6% drug release in 40 2% SSG showed least and 50min. However the disintegration time of 22 sec. Fig. formulation L7 containing 8 combination of superdisintegrants SSG and CC-Na showed 98.6- 2% SSG and 3% CC-Na gaves 100% drug release within 30min. fast results.The formulation L7 Both L7 and L8 gave excellent containing 2% SSG and 3% CC- results Na showed that 91.6% drug 4 Conclusions release occur after 10min and formulation L8 containing 5% Oral dispersible tablet was SSG and 3% CC-Na showed prepared to provide immediate 81.9% drug release after 10min. release effect of lisinopril maleate. So the formulation L7 and L8 Superdisintegrants like SSG and showed maximun release after CC-Na were used for preparation 10min. In-vitro drug release study of oral dispersible lisinopril of lisinopril maleate showed rank maleate tablet. Polymers were order of CC-Na > SSG. As the used alone or in combination for concentration of superdisintegrant preparation of oral dispersible increased drug disintegration tablet. Direct compression method occured in short time. Hence was used. In the present study it based upon in-vitro disintegration can be concluded from the time and dissolution time L7 was characterization of fast dissolving selected for formation of lisinopril tablets of lisinopril maleate that layer. Lisinopril tablets prepared formulation containing using SSG showed 94.4-98.6% combination of SSG and CC-Na drug release occur within 40- is most acceptable. Further in 50min where as lisinopril tablets vivo studies in human volunteers prepared using CC-Na showed are required to correlate in vitro 98.6% drug release within 40- release data. 60min where as formulations L7 5.Acknowledgement and L8 containing combination of 9 The authors are grateful to Razee Pharmaceuticals Pvt Ltd Lahore & Therapeutics Pvt Ltd Lahore, for providing chemicals. Authors Werrick Pharmaceuticals Pvt Ltd are thankful to their parents also Islamabad and Unexo for their moral support. Table: 1. Composition of lisinopril maleate oral fast disintegrating tablets. Batch Code L1 Lisinopril 8.3% SSG 5% CC-Na - L2 L3 L4 L5 L6 L7 L8 8.3% 8.3% 8.3% - 8.3% - 8.3% - 8.3% 8.3% 4% - 3% - 2% 3% 5% 4% 3% 3% 2% Mg-Stearate 4.1% 4.1% 4.1% 4.1% 4.1% 4.1% 4.1% 4.1% 0.5% 0.5% 0.5% 0.5% 0.5% 0.5% 0.5% 0.5% 2% 2% 2% 2% 2% 2% 2% 2% 80.1 81.1% 82.1% 80.1% 80.1% Cab-O-sil Aspartum MCC 80.1% 81.1% 82.1% Sodium Starch Glycolate, Cross carmellose sodium, Microcrystaline cellulose 10 Table 2 Pre-compression parameters of lisinopril maleate Batch Code Bulk Density±SD Tapped Density±SD Hausner’s Ratio±SD Car’s Index±SD Angle Of Repose±SD L1 0.24±0.012 0.31±0.025 1.29±0.005 22.58±0.015 22.17±0.718 L2 0.20±0.014 0.32±0.020 1.60±0.208 37.5±0.288 22.32±0.582 L3 0.22±0.011 0.34±0.015 1.54±0.011 35.29±0.538 27.87±1.019 L4 0.27±0.015 0.35±0.014 1.29±0.015 22.85±0.557 21.9±0.133 L5 0.23±0.010 0.34±0.030 1.47±0.010 32.35±0.870 23.14±0.251 L6 0.25±0.028 0.38±0.015 1.52±0.017 34.21±0.530 23.47±0.501 L7 0.21±0.028 0.36±0.021 1.71±0.011 41.66±0.912 30.04±0.628 L8 0.26±0.028 0.32±0.005 1.23±0.026 18.75±0.598 22.43±0.987 Table 3 Post-compression parameters of lisinopril maleate Post compression parameters of Lisinopril maleate Batch Code Thickness±SD (mm) Diameter±SD (mm) Weight variation ±SD Hardness±SD (kg/cm2) L1 3.58±0.125 6±0.123 120.53±1.184 4.21±0.052 L2 3.53±0.387 6±0.122 120.62±1.425 4.7±0.08 L3 3.65±0.180 6±0.232 121.01±1.593 4.44±0.072 L4 3.34±0.040 6±0.163 120.62±1.246 4.66±0.057 L5 3.30±0.026 6±0.244 120.43±0.783 4.27±0.02 L6 3.33±0.015 6±0.334 120.72±0.784 4.32±0.053 L7 3.33±0.041 6±0.297 120.72±0.479 4.55±0.05 11 L8 3.42±0.083 120.45±0.643 6±0.465 4.3±0.047 Table: 4 Post compression parameters of Lisinopril maleate Batch Code Percentage friability (%age) L1 0.82±0.095 Drug content uniformity 99.1%±0.012 Wetting time(sec) In-vitro disintegration time (sec) 27±0.095 33±0.052 L2 0.65±0.464 97.4%±0.342 33±0.053 L3 0.74±0.034 96.6%±0.987 45±0.034 52±0.874 L4 0.98±0.256 97.5%±0.782 28±0.054 33±0.154 L5 0.65±0.368 95.7%±0.562 36±1.005 42±0.987 L6 0.90±0.763 98.0%±0.132 21±0.098 26±0.0543 L7 0.98±0.034 93.9%±0.087 17±0.432 22±0.987 L8 0.74±0.0457 95.3%±0.063 20±0.876 24±0.346 37±0.132 4.8 4.6 4.4 4.3 4.5 4.6 4.3 4.2 L6 L5 4.7 4.2 4.4 4.1 4 3.8 L8 L7 L4 L3 L2 Hardness(kg/cm2) Figure:1 Hardness of lisinopril maleate 12 L1 Drug content uniformity Drug content uniformity… 98.00% 95.30% L8 95.70% 93.90% L7 L6 L5 97.50% 96.60% 97.40% L4 L3 99.10% L2 Figure: 2 Drug content uniformity of lisinopril maleate 0.74 L8 0.98 L7 0.9 L6 0.98 0.65 L5 L4 0.74 0.65 0.82 L3 L2 L1 Percentage friability Figure: 3 Friability of lisinopril maleate 13 1.2 1 0.8 0.6 0.4 0.2 0 L1 Wetting time(sec) Wetting time(sec) 45 36 20 17 21 L8 L7 L6 28 L5 L4 L3 31 27 L2 L1 Figure: 4 Wetting time of lisinopril maleate In-vitro disintegration time 42 24 22 26 L8 L7 L6 L5 52 33 L4 L3 37 33 L2 L1 Figure: 5 Disintegration time of lisinopril maleate 14 120% 100% Percentage Drug Release 80% 60% L1 40% L2 L3 L4 20% 0% 0 20 Time 40 60 80 Figure: 6 Percentage drug release from formulation L1-L4 120% 100% 80% Percentage 60% Drug Release L5 L6 L7 L8 40% 20% 0% 0 20 40 Time 60 80 Figure: 7 Percentage drug release from formulation L5L8 in 0.1N HCl 15 6. Reference drug delivery –A Review. 1. Fu, Y., Yang, S., Jeong, S. H., Kimura, S., & Park, K. (2004). Pharm. Sci. Orally fast disintegrating tablets: Tech 2000; 4[3]: 138‐145 developments, technologies, taste- 6. Swamivelmanickam, M., masking and clinical Valliappan, K., Reddy, P. G., studies. Critical Reviews™ in Madhukar, A., & Manavalan, R. Therapeutic Drug Carrier (2009). Preformulation studies for Systems, 21(6). amoxicillin trihydrate and 2. Bandari, S., Mittapalli, R. K., dicloxacillin sodium as mouth Gannu, R., & Rao, Y. M. (2008). dissolve tablets. Int J ChemTech Orodispersible tablets: An Res, 1(4), 1032-5. overview. Asian journal of 7. Ito A, Sugihara M, Development o pharmaceutics, 2(1), 2. f oral dosage forms for elderly pati 3. Chang R K, Guo X, Burnside B ents: Use of ager as base of A, Couch R.A, rapidly disintegrating oral tablets. Fast dissolving tablets. Pharm. Tech. Chem. Pharm. Bull 1996; 11[44] : 2000; 6[24]: 52-58. 2132‐36. 4. Rajitha K, Shravan Y K, 8. Banweera, J., Pandeyb, S., & Adukondalu D, Ramesh G, Rao Pathaka, A. K. (2010). Y M. Formulaton and evauation Development and optimization of of orally disintegrating tablets transdermal system of lisinopril of buspirone. Int J Pharm Sci and dehydrate: Employing permeation Nanotech 2009; 4[1]: 327‐334 enhancers. Iranian Journal of 5. Sastr Y S V, Nyshadham J R, Pharmaceutical Sciences, 6(4), Fix J A, Recent 245-251 technological advances in oral 16 9. Naveed, S., Sultana, N., & release bilayer tablet for biphasic Arayne, M. S. (2012). drug release: A novel approach in Simultaneous determination of management of diabetes. Journal lisinopril and H2 antagonists in of Pharmacy Research, 4,20-25. API, formulations and human 15. Raffick, M. M., Mohamed, J. M., serum by using two different Vetriselvan, S., Vignesh, M., HPLC systems. Medicinal Selvakumar, K., Parkavi, V., & Chemistry Research, 21(12), Ruby, J. J(2012). Preparation and 4037-4042 evaluationof in-vitro release 10. Gaffar, I. K. S. A. (2011). kinetics of novel bilayer Formulation and evaluation of metoprolol succinate as sustained bilayer tablets of lisinopril and release and amlodipine besylate as gliclazide. immediat release tablets.3(2),285- 11. Yeola B S, Pisal S S, 297 Paradkar A R, Mahadik K R, 16. Malpani:, A. (2009). Formulation New of lisinopril dehydrate tablet and drug delivery systems.Indian Drug study effect of extent of s 2000; 7[ 37]: 312‐318. granulation on response variable..International Journal of 12. Pharmacopoeia, B. (2009). British Pharmaceutical Science 1, 132- pharmacopoeia commission 139 13. Patel, N. J., Lakshmi, C. S. R., 17. Nanjwade, V. K., Manvi, F. V., & Patel, H. P., & Akul, S. (2011). Formulation and evaluation of Nanjwade, B. K. (2013). Oral dispersible tablets of Formulation and Evaluation of cinnarizine using direct Dispersible Tablets of compression Lomefloxacin HCl. Int. J. Drug technique. IJPSR, 2(4), 961-67. Dev. & Res,5(1), 103-113. 18. Shajan, N. (2013). Formulation 14. Pattanayak, D. P., Dinda, S. C., & Narayan, U. L(2011). Formulation and evaluation of bilayer tablets of and development of sustained doxofylline HCL and montelukast 17 sodium for treatment of asthma, 23. Furtado, S., Deveswaran, R., IJAP,3(1),70-76 Bharath, S., Basavaraj, B. V., 19. Amrutkar, P. P., Patil, S. B., Abraham, S., & Madhavan, V. Todarwal, A. N., Wagh, M. A., (2008). Development and Kothawade, P. D., & Surawase, R. characterization of orodispersible K. (2011). Design and evaluation tablets of famotidine containing a of taste masked chewable subliming agent. Tropical journal dispersible tablet of lamotrigine by of pharmaceutical research, 7(4), melt granulation. International 1185-1189 Journal of Drug Delivery, 2(2). 24. JAIN, A., JAIN, C., GAUR, K., KAKDE, A., MEENA, M., & 20. Chitra Karthikeyini, S., Nalini, G., NEMA, R.(2005). & Sachin Sundar, N.(2013). FORMULATION AND Fabrication & evaluation of CHARACTERIZATION OF fluoxetine and vitamin e fast ORO-DISPERSIBLE TABLET release bilayer tablets in OF HISTAMINE BLOCKING depression management.3(1), 107- AGENT. International Journal of 112 Pharmaceutical Formulation & 21. Talasila Sudha, Senthilkumar, Analysis, 37. Ezhilmuthu and Pendyala 25. Sreeivas. S.R (2005): Yamini(2012). Formulation and Orodispersible Tablets: New- In-vitro characterization of Gelatin fangled Drug Delivery System-A Micro spheres loaded with Review. Indian J. Pharm. Educ. Lisinopril dehydrate. International Res. 39; 2005: 177-180). journal of pharmaceutical and 26. Biming, W. (2001). Preparation of chemical sciences, 1(2). 613-622 Dispersible Ribavirin Tablet 22. Biswal, B., & Bhandari, M. P. A. [J]. China Pharmacist, 6, 010. (2011). Characterization of 27. Jadhav, S. B., Kaudewar, D. R., trimetazidine dihydrochloride Kaminwar, G. S., Jadhav, A. B., floating bilayer matrix tablets. Kshirsagar, R. V., & Skarkar, D. 18 M. (2011). Formulation and evaluation of dispersible tablets of diltiazem hydrochloride. Int J Pharma Tech Res, 3(3), 13141321. 28. Sharmin Rahman, M., Al Masum, A., Islam, S. A., & Reza, M. S. (2012). Formulation and Evaluation of Bi-layered Sustained Release Matrix Tablets of Tramadol Hydrochloride. Journal of Applied Pharmaceutical Science, 2(06), 129-134. 29. Tekade, N. P., Bhajipale, N. S., Ganesan, V., Thenge, R. R., & Dewade, D. R. (2010). Orodispersible tablets of lansoprazole formulation, characterization and in vitro evaluation. Int. J. ChemTech Res, 2(1), 400-05. 30. Swamivelmanickam, M., Valliappan, K., Reddy, P. G., Madhukar, A., & Manavalan, R. (2009). Preformulation studies for amoxicillin trihydrate and dicloxacillin sodium as mouth dissolve tablets. Int J ChemTech Res, 1(4), 1032-5. 19