Net Zero Speech Material

advertisement

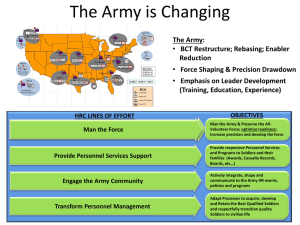

Net Zero Speech Material Kristine’s Keynote on 27 Aug 2014 (Excerpts) U.S. SOUTHCOM / U.S. Army South, Sustainability and Contingency Basing III, San Antonio, TX Good morning. It is a pleasure to be here to discuss progress and best practices from the United States Army Net Zero Initiative. I would like to thank United States Southern Command and U.S. Army South for inviting me to participate. It is an honor and a great opportunity to be able to engage with our partner nations. Today I intend to share the Army’s sustainability story through the lens of Net Zero. For the Army, Net Zero is considered a Force Multiplier. Achieving Net Zero reduces our energy, water, and waste demands, which frees up resources that can then be used to achieve the mission at hand. The Army Net Zero Initiative integrates and implements different best practices at the installation level, looking for holistic solutions. We have performed case studies on how best to move beyond permanent installations to the contingency basing environment. The first part of my presentation will focus on the overall Net Zero Initiative. The second part will focus on applying Net Zero concepts to contingency bases. Since its inception in 2011, the Net Zero Initiative has been the cornerstone of Army sustainability efforts. Building off of the efforts at our Net Zero Pilot Installations, we were very pleased that the Secretary of the Army issued a Net Zero Installations Directive in January 2014. This Directive articulates the Army’s vision to appropriately manage its natural resources, with a goal of striving towards Net Zero installations in energy, water, and solid waste. This effort is of great importance for the U.S. Army because our ability to accomplish our mission depends on secure, uninterrupted access to energy, water, and other natural resources, both at home and abroad. Let me put the U.S. Army’s energy and water use in perspective. The Army manages almost one billion square feet of building space. We have over 100,000 homes on our bases, utilized by 2.2 million Soldiers, families and civilians. Our installations and posts around the world are comparable to 152 small cities. With this amount of people and infrastructure, in fiscal year 2013 (FY13), Army facilities spent $1.3 Billion on 72.7 Trillion British Thermal Units (BTUs) of energy. In addition, the Army spent $2.5 Billion on 586 Million Gallons of operational liquid fuel purchased. With respect to water, 1 in FY13, the Army consumed 47 billion gallons of potable water on our installations, which is equivalent to over 71,000 Olympic-sized swimming pools. The Army cares about our sizable sustainability bootprint because energy and water supply shortfalls represent a strategic vulnerability – increasing risk to our mission, our pocketbook, and our reputation. Ensuring energy and water security through increased efficiencies, distributed generation, and diligent management of resources reduces this vulnerability. Energy and water security reduces physical risk to our Soldiers, financial risk associated with rising energy prices, and reputational risk associated with mission failure. The Army also cares about continuing a legacy of leadership and innovation. That is why the Army is seizing the opportunity to lead the nation in implementing net zero solutions, through sustainable practices, starting with our people and our infrastructure. As the U.S. Army manages our large sustainability bootprint, we work to strike a balance between overlapping and sometimes competing objectives. For example, we are balancing our goal to increase energy security, surety, and reliability with goals to reduce fuel costs, foreign sources of energy, and environmental concerns. We are also striving to meet or exceed the performance targets established in U.S. Federal mandates. Installations and surrounding communities are experiencing increased power outages due to the impact of natural disasters and a vulnerable electrical distribution system. As depicted in the graph on the lower left, in the last ten years, we have seen over a four-fold increase in power interruptions on our Army bases. Earlier this summer, over 35 percent of the mainland United States was experiencing drought conditions. Appropriately managing our natural resources and complying with Federal mandates is a challenge that the Army has been addressing through technologies, policies, and initiatives, such as Net Zero. Through the principles of integrated design, the Net Zero strategy strives to bring the overall consumption of energy, water, and waste on our installations down to an effective rate of zero. The map identifies the locations of our 17 Net Zero pilot installations. The pilot installations volunteered to be a part of the Net Zero challenge and span diverse geographies, missions and functions. 2 As the Initiative progressed, it became clear that the Net Zero hierarchy, which is the framework for the Net Zero Strategy, applies differently to energy, water and waste. On the right, you see the alternate versions that were refined into subordinate hierarchies for each area of Net Zero. The hierarchies together articulate an overall approach that is not only consistent across installations, but also allows for unique solutions to emerge for each installation in accordance with their specific circumstance. Common to all hierarchies are Reduction and Awareness/Culture Change. In addition to the hierarchies, the definitions of Net Zero Energy, Water, and Waste also evolved. The Original Net Zero Energy Definition was to produce as much energy on site as the installation uses over the course of a year. The Net Zero Energy definition was clarified to emphasize the need to reduce overall energy use, increase efficiency, and implement recovery and co-generation opportunities, meeting the remaining energy demand with renewable energy The Net Zero Energy hierarchy focuses first on energy reduction through conservation, followed by energy efficiency. Once energy use is reduced as much as possible and energy efficient technologies have been implemented, the hierarchy dictates that energy recovery and cogeneration be investigated. Remaining energy loads are to be met with the use of on-site renewable energy sources. This approach enables a Net Zero Energy installation to produce as much renewable energy as it uses over the course of a year. Note that we do not START with renewable energy. The reason Reduction is at the top of the inverted triangle is because reducing the amount of energy consumed is the first step in any Net Zero effort. Renewable energy is the bottom, and smallest portion, of the inverted triangle. As mentioned, spanning all of the energy hierarchy steps are “Increased Energy Security” and “Awareness/Cultural Change.” Our installation energy managers understand that achieving a resilient, Net Zero installation requires a systems-of-systems, holistic approach. Holistic approaches to achieving Net Zero Energy include dramatic demand side energy use reduction; the right mix of energy generation technologies and strategies that also increase 3 energy security; building clusters served by smaller central utility plants and microgrids; and flexible implementation strategies to account for technology innovations and mission changes. As mentioned, the Net Zero Installations Directive expands the Net Zero Initiative beyond the pilot installations to all permanent Army installations. The intent is that all installations evaluate the feasibility of achieving Net Zero and then implement, to the maximum extent practicable and fiscally prudent, policies, procedures, and technologies that advance their Net Zero goals. Thus, the Army is journeying towards Net Zero as our installations take overarching actions to Initiate, Assess, Roadmap and Implement. Specific activities and actions taken to implement Net Zero include: 1) establishing your baseline, 2) assessing your potential, and 3) integrating results into existing programs. All activities and actions are based on collaboration. Establishing your baseline may involve completing an energy audit, conducting a water balance assessment or a material flow analysis and waste characterization study. It is important to state that we are working to make these actions a part of the “normal” actions each installation is required to take. Assessing your potential for future activities involves conducting a renewable energy audit, identifying water re-use opportunities, or identifying additional material re-use and waste diversion opportunities. Net Zero Roadmaps tie these efforts together by building a strategic frameworks from which the sites can implement initiatives to help drive them towards Net Zero. They include project lists and actions to meet a pilot installation’s Net Zero goals by fiscal year 2020. An example energy roadmap shows the sequencing of projects to reach Net Zero, with recommended: Energy efficiency improvements Opportunities for waste heat recovery and combined heat and power, and Renewable energy projects As the roadmaps are implemented, the installation should see a steady reduction in energy consumption, and a steady increase in renewable or alternative energy technologies. 4 Results are then integrated into existing master planning and management plans. Net Zero is the concept we use to move the ball forward. It does not replace our master plans and procedures – it is our end state goal. Implementation would not be feasible without internal and external collaboration. Internally, within the Army, the goal is for information learned at one Net Zero pilot installation to be shared with other Army installations. The Net Zero team at the Headquarter-level currently hosts monthly collaboration calls and periodic progress meetings with representatives from our energy, water, and waste pilot installations, their Commands, and those providing technical support. We have established cross-functional Net Zero teams to document and share information and stories to help the non-pilot installations and contingency bases begin their journeys toward Net Zero. Externally, the U.S. Army has partnered with: Other Federal agencies, such as the Environmental Protection Agency (EPA), and the Department of Energy; With industry through public-private partnerships, and With municipalities and communities -- to develop mutually beneficial solutions at the local and regional levels. Collaborating with Department of Energy laboratories helps us leverage their expertise and research skills to gather data for the energy assessments, water balance reports and roadmaps. As we operate in a financially constrained environment, the Army has significantly increased its use of public-private or third-party financing for energy and water projects. Utilities privatization is an example of a smart public-private partnership because utility operations are not a core military function and we know that, in many cases, the private sector can fix Army utility systems for less money than it would cost the Army. On the local level, Fort Hood in Texas is working with Habitat for Humanity to deconstruct old buildings to enable reuse of the buildings’ salvageable materials. 5 Capturing best practices from activities at our Net Zero pilot installations is a crucial step in institutionalizing Net Zero across the Army enterprise. Best practices for energy begin with conducting a thermal building envelop analysis. Infra-red thermography was completed on the largest buildings as well as the largest energy-using buildings at the pilot installations. This enabled installations to identify areas with heat loss, then target those areas for repairs. Other green building practices include daylighting and deep energy retrofits. Installing Energy Management Control Systems give the installation Energy Manager the ability to control any energy-consuming device that’s connected to the system. This also allows the Energy Manager to control those devices for demand reduction. Employing an energy efficiency specialist to work with existing staff to reduce energy consumption as well as the cost of energy at the installation is another best practice. A key to Net Zero Energy success is to pursue alternative or third-party financing, which are funding opportunities that fall outside of the Army’s budget. The primary mechanisms in the U.S. are Energy Savings Performance Contracts (ESPCs) and Utility Energy Service Contracts (UESCs). Under these contract vehicles, the Company or Utility provider uses its own funding to implement energy reduction projects. They are “paid back” for their investments through the energy savings realized from the project. For example, in 2012, the U.S. Army Corps of Engineers – Huntsville office awarded a $34 million task order contract to Johnson Controls to install wind power generation, solar photovoltaic systems, and other energy conservation measures at Fort Buchanan and 11 reserve centers in Puerto Rico. The overall projected project savings is greater than 37,800 MBtu and $2.6M per year. • Work in the task order includes air cooled chiller replacement; the installation of energy management controls system; heating, ventilation and cooling (HVAC) system upgrades and window/split air conditioning system retrofits; energy-efficient interior and exterior lighting, including upgrades to light-emitting diode (LED) street lighting; occupancy sensors; renewable energy including a 1.2 MW solar photovoltaic system, solar thermal water heating, and 825 kW wind power generation; water/sewer conservation and irrigation system; and retro-commissioning services that seek to improve how building equipment and systems function together. Finally, Energy Master Planning enables the integration of efficiency and renewable energy options that wouldn’t otherwise be feasible in a single building. Examples include the development of a Central Utility Plant to serve an entire Brigade complex. This approach is 6 easier to maintain and typically more cost effective than individual boilers for each building or longer distribution lines necessary to connect to only one installation-wide utility plant. [Transition to contingency bases] Over the past three years, we have learned that success in the Net Zero initiative relies on flexibility and adaptive management practices. Each installation is different but can apply best practices to its own set of needs and resources to become more sustainable. The same holds true for the contingency basing environment. The many reasons for pursuing Net Zero at permanent Army installations are also relevant to contingency bases. In addition to sustainability, Army operational energy, water, and waste affect a wide range of military capabilities – including maneuverability, communications, intelligence, surveillance, and reconnaissance. Energy and water dependence, as well as waste management, drives operational vulnerabilities in several activities, such as risk associated with long distance supply routes in barren and hostile terrain; and risk involved with lack of redundant, or backup, portable energy solutions. Now let’s take a look at how we are trying to increase mission effectiveness by applying the Net Zero Initiative to Contingency Bases. The examples in my presentation are taken from a recent study of a Net Zero pilot contingency base. Just as with permanent installations, the Net Zero approach begins with establishing your baseline usage. Establishing a baseline is important because it links energy, water, and waste data with base activities to help identify and prioritize opportunities for Net Zero actions. The example contingency base from our study meets all of its electricity requirements by using diesel electric generators that provide about 17 Megawatt (MW) of generation nameplate capacity. Connected to the power plant are ten to fifteen substations that distribute the electricity to a portion of the total base load. Several of these substations also have a 1 MW backup generator that only operates in the event the power plant is disrupted or lost, which represents addition capacity. In addition, about 200 spot generators are distributed throughout the camp to meet the remaining electricity needs. Because of the high ambient temperatures at this camp, the present operating practice is to limit electrical loading of the power plant generators to 70% of the generator’s nameplate rating. Consequently, the power plant has a generator nameplate capacity that is higher than operating capacity. 7 Because all of the electricity needs are met by liquid-fueled generators, the overall energy consumed for the base can be determined by calculating the amount of million British Thermal Units (MBtu) consumed. As seen in the top left graph, the study identified that minimum fuel consumption, about 100 thousand gallons (Kgals), occurred in February 2013 and maximum fuel consumption, about 270 thousand gallons (Kgals), occurred in July 2013. Monthly records for energy production from the power plant also indicate minimum electricity requirements of about 1,300 MW-hours occurred in February 2013 and maximum requirements of about 3,800 MW-hours occurred in July 2013. The takeaway is that climate is the biggest driver of monthly fuel consumption on the base, not fluctuations in population or number of days in each month. The bottom graph shows how variances in daily temperature align with power plant electrical loading, with blue representing energy production in February and red representing power plant production in July. Organizing fuel and water consumption, as well as waste generation, by activity establishes a camp-wide perspective for Net Zero assessment, planning, and implementation. An activities-based approach ensures that base camp systems are addressed in their entirety, not piecemeal. It also ensures that the organizations with primary responsibility for certain activities (for example military operations and training) will have primary responsibility for the impact that these activities have on energy, water, and waste. Thus, at the contingency base pilot, Activity Groups were established based on camp operations. The Activity Groups with the highest fuel use (as a percent of total, using February 2013 data) at are Billeting, Mission Support, and Utilities, as shown in the slide. Overall fuel use is fairly even amongst these, at 32%, 27% and 26%, respectively. This demonstrates that nearly all energy use is driven by these three Activities. Mission Support includes the ammunition supply point, storage, motor pools, convoy staging, explosive ordnance disposal operations and staging, warehouses, vehicle operations, wash rack, refueling shop, parking shed, maintenance shop, fire station, Petroleum, Oil and Lubricant operations, retail fuel, bulk fuel, and armament maintenance. Billeting includes the Logistics Support Area, all housing and support functions (parking, latrine units, self-serve laundry, lighting). Utilities activities include communications, power plant, water treatment facility, and wastewater lagoons. 8 In July, fuel use rose dramatically for all three of these Activity Groups, even more so for the Utilities Activity Group, which was found to have even higher per capita daily use in July than Mission Support. The takeaway is that climate controlled activity groups consume the most energy. HON Hammack, EPA NZ Communities Presentation, 25 Feb 2014 (Excerpts) With the time remaining, I would like to highlight work being done at specific Net Zero Pilot Installations. [Fort Hunger Liggett] I mentioned that NREL and PNNL are helping us to develop roadmaps for our Net Zero installations. The Fort Hunter Liggett Energy Roadmap concluded that this Army Reserve installation can achieve Net Zero Energy by 2020, through energy efficiency and renewable energy technologies. Due to the high cost of energy in California, the net zero solution can save the installation approximately $25 million over the 25-year analysis period. Energy efficiency savings are estimated to be around 40% of FHL’s baseline energy consumption. Sample recommended efficiency improvements include lighting retrofits, building envelope upgrades, and metering. The pie graph shows a summary of renewable energy project recommendations, which include solar photovoltaic, solar ventilation preheating, solar hot water, skylights, and ground source heat pumps. The photo on the right is a 1MW carport style PV system at FHL, which is currently being expanded to 3 MW. The carport solar array generates electricity for the installation while providing shade for the vehicles. PG&E, the installation’s utility provider, recently announced that it will upgrade transmission lines to the installation, opening the door for power to be fed onto the grid in times of overproduction. This reduces the installation’s need for energy storage, making net zero not only feasible, but also economical for Fort Hunter Liggett. [Oregon National Guard] The Oregon Army National Guard is a unique Net Zero Energy pilot because it is working on a state-wide effort to achieve Net Zero. 9 It quickly embraced the advantages of being energy secure and has extensively increased their energy efficiency. They have also been aggressively pursuing renewable and alternative energy options. The Oregon Army National Guard began by using Federal stimulus funds to install 500 solar panels in Christmas Valley, for a total installed capacity of 150.5 kW. The Phase 2 goal for the site is to have a 20 MW capacity by FY 2020. Camp Rilea, of the Oregon Army National Guard, has an existing 3 kW Wind project with an additional 2.2 MW proposal. This is an example of where we worked with NREL to conduct the renewable energy assessment. The Oregon Guard also completed the installation of geothermal and solar PV on its Ontario base, totaling 103 kW. HON Hammack, ASHRAE, NC, 11 March 2014 (Excerpts) Best practices and lessons learned are often turned into Army policy. In 2010, we updated our Sustainable Design and Development Policy for new construction and major renovations, requiring new vertical construction to achieve the Leadership in Energy and Environmental Design (LEED) Silver rating, and follow ASHRAE standard 189.1 as the baseline. In 2013 we updated it again to include: Siting new construction, preference shall be given to brownfields and other previouslydeveloped lands, proximity to existing supporting infrastructure (such as utilities), and connectivity to transportation modes/networks where feasible. All new construction and major renovations require building-level monitoring accomplished by smart meters installed to capture consumed utilities (for example, electricity, natural gas, water, and steam). For the mitigation of the heat island effect, roof design strategies are to consider the climatic regions and the thermal load of the building. For storm water management, projects will maximize the use of existing site topography including soils, flora, slope, and hydrology to minimize site disturbance including clearing and soil grubbing activities. To conserve the use of outdoor water, the Sustainable Design and Development Policy calls for the use of native plant species and the consideration of dry-scape architectural alternatives – as 10 well as the use of non-potable water. Invasive plants are not to be planted on sites and any existing invasive plants are to be removed. By the end of calendar year 2013, the Army had completed 360 LEED certified projects. Some projects have more than one building in them, so our LEED building count is over 500. Taking a balanced approach to site design, energy and water conservation, waste management and occupant comfort, these projects – along with the Army Sustainable Design and Development Policy – collectively help installations achieve Net Zero. Remember, it is a multi-pronged approach. Fort Carson, Colorado is one of two installations striving to be an integrated Net Zero Installation, achieving net zero for energy, water, AND waste. It has a long-standing sustainability program with 56 LEED certified buildings. For this reason, GSA chose Fort Carson for a case study on testing Federal green building performance. Our LEED Platinum buildings include: • Three buildings in Colorado: 2 at The Ft Carson, CO Wilderness Road Complex Brigade Battalion HQ building in 2012 and the Company Ops Center in 2013. And one for Colorado Army National Guard, their Windsor Readiness Center in 2013 • The Ft Bragg, NC Community Emergency Services building completed in 2012 • Alabama National Guard: Pelham Range Readiness Center (2012) Fort Bragg’s Community Emergency Services Station was certified LEED Platinum in March, 2012. The station reduces potable landscape water use by 50 percent and baseline indoor water use by 20 percent. The project improved its energy efficiency above baseline building performance rating by 31.5 percent and has 8 percent onsite renewable energy. It is constructed of 2.5 percent rapidly renewable materials and 50% Forest Stewardship Council-certified wood products. 75 percent of the occupied space has daylighting and 90 percent of the occupied space has quality views. The Fort Belvoir hospital in Virginia was certified LEED Gold in July 2012. It is the largest LEED gold certified hospital in the world at 1.27 million sq ft facility with 3 patient centers. We used evidence-based design to improve patient outcomes 11 27.6% less energy use than typical hospitals 20% reduction in potable water use 50% reduction in landscape water use 61.9% of site restored with native & adaptive plants Mr. Kidd, Yale, 2013 WHY does the Army care about sustainability? o Sustainability is about preserving CHOICE for the Army of the future. o By implementing sustainability principles and practices to achieve energy, water and waste objectives, the Army enhances mission effectiveness. For example, energy-informed operations provide operational edge, increase flexibility and reduce risk to our Soldiers. Sustainable installations becomes platforms of stability through resiliency, characterized by being highly efficient, having on-site power and water generation, smart infrastructure, and resource integration. Net Zero is a force multiplier. Now that we’ve discussed some of the success stories, let us take a closer look at WHAT IS ENABLING the Army to become sustainable. The Army is creating a culture that recognizes the value of sustainability, measured not just in terms of financial benefits, but benefits to maintaining mission capability, quality of life, relationships with local communities, and the preservation of options for the Army’s future. Army Leadership is taking both a top-down and bottom-up approach to achieve sustainability. o The Under Secretary of the Army is the Sr. Sustainability Official. o As high levels are setting the overall direction, the Net Zero pilot sites are identifying themselves for participation from the bottom up. The Army is obtaining buy-in from Sr. Leaders that sustainability objectives cut across the entire Army Enterprise. 12 o In FY12, the Army adopted energy security and sustainability objectives into the Army Campaign Plan (ACP). The elevation of energy security and sustainability objectives into a key strategy document during a fiscally constrained environment reflects the increased importance of sustainability in enhancing mission effectiveness. o The ACP asks Sr. Leaders to continue to speak about energy security, water security and sustainability as a driving force for culture change. o The launch of smart Operational Energy use campaign: The Power is In Your Hands (2012), supported by the SecArmy, CSA & SMA. o Incorporate sustainability-informed decision-making into schoolhouse curricula RDT&E: the Army is a deployment vector for new technologies: Back up The DoD’s vision of sustainability is “to maintain the ability to operate into the future without decline – either in the mission or in the natural and man-made systems that support it.” EO 13514 definition of sustainability: “Sustainability and sustainable mean to create and maintain conditions, under which humans and nature can exist in productive harmony, that permit fulfilling the social, economic, and other requirements of present and future generations of Americans.” 13