Water-Soluble Chloride Ion Content, % Figure 2 Effect of Particle

advertisement

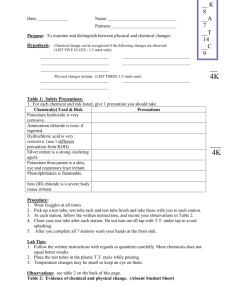

CONCETE 1 INTRODUCTION It has long been recognized that chloride ions play a major role in the corrosion of steel in concrete. The chloride ions may originate from the ingredients of the concrete mixture, or may diffuse through the hardened concrete. Most building codes attempt to control corrosion-induced deterioration by placing limits on the chloride ion content of the mix ingredients and by specifying the quality of the concrete and thickness of concrete cover appropriate to the exposure conditions. A number of the aggregates used in concrete in North America contain significant concentrations of chloride ions. This is particularly true in the case of the carbonate aggregates used in Southern Ontario. The chloride ion contents from some sources are sufficiently high to exceed the limits specified in the Canadian standard 'Concrete Materials and Methods of Concrete Construction' for prestressed concrete and, sometimes, for reinforced concrete. This paper expands upon an earlier paper1 and describes a series of laboratory investigations undertaken to investigate whether the chloride ions in the aggregate depassivate embedded reinforcement, the development of a test method to discriminate between 'available’ and 'unavailable' chloride ions, and the results of a field survey of the corrosion performance of bridge structures containing chloride- bearing aggregates. 2 CHLORIDE LIMITS IN CONCRETE Establishing limits for the chloride ion content of mix ingredients in concrete is very difficult for three reasons: i) Chloride ions are present naturally in many concrete ingredients and specifying a zero chloride ion content is therefore unrealistic. ii) There is no agreement on a test procedure which can be used to determine the chloride ions available to depassivate the steel. iii) The service environment often cannot be described with sufficient precision to determine the risk of corrosion. 2.1 Corrosion Threshold Concept Although a zero limit for chloride ions is impractical, neither is it necessary because it has been known for a long time that small concentrations of chloride ions in the concrete do not result in an unacceptable level of corrosion of embedded steel. This observation gave rise to the concept of the chloride corrosion threshold.2 The concept of a threshold implies that there exists a chloride ion concentration below which steel is 'safe' from corrosion and above which, an unacceptable level of corrosion may occur if other necessary conditions, principally the availability of oxygen and moisture, exist to support the corrosion reactions. The concept leads to the initiation-propagation model for corrosion damage3 but it must be remembered that the corrosion threshold value is not a constant value for all concrete mixtures. The quantity of chloride ions required to depassivate the steel depends on several factors, including the chemical composition of the cement2 the ratio of the concentration of hydroxyl ions to chloride ions,4,5 and the type of cation.6 The corrosion threshold value is also dependent on the method of testing for chloride ion content. 2.2 Test Methods Test methods for measuring the chloride ion concentration in concrete or concrete ingredients consist of two parts, extracting the chloride ion into solution and measuring the concentration of chloride ions in the solution. Once in solution, the chloride ion concentration is measured by a conventional titration using a standard silver nitrate reagent or by a suitable, calibrated ion-selective electrode. Test methods therefore differ principally in the method used to extract the chloride ions from the concrete and variations on two basic methods are in common use: digesting in nitric acid and dissolving in water. An alternative approach is to extract the pore water by applying high pressure to the concrete, though this method requires sophisticated equipment, and there is concern as to whether the fraction of pore water extracted is representative of the pore water as a whole. In North America, the standard acid-soluble test method is AASHTO T 260 'Sampling and Testing for Total Chloride Ion in Concrete and Concrete Raw Materials'.7 A representative sample is ground to pass through a 300 p.m sieve. The chloride ions are extracted by digestion in nitric acid and then measured by titration. A water-soluble test method, also specified in AASHTO T 260, is veiy similar to the acid-soluble method. However, the rate of dissolution in water is affected by the extraction time, the temperature of the water and the particle size, and these must be controlled carefully. As a consequence, the measured value is a function of the test method. The chloride ions are extracted by boiling in water for 5 minutes and are then allowed to stand at room temperature for 24 hours prior to analysis of the aqueous phase. The water-soluble test came into general use because the procedure was quicker than the acid extraction and it was thought (erroneously) that the result of the test gave the concentration of chloride ions available to support corrosion. Based on the work of Lewis,8 further studies at the Federal Highway Administration Laboratories in the early 1970s 9 showed that for hardened concrete subject to externally applied chlorides, the corrosion threshold was 0.20% acidsoluble chloride ions by mass of cement. The average ratio of water-soluble to acid-soluble chloride ions was reported to be 75 to 80%.10 although the original work11 indicates an average of 77% for chloride ions added at the time of mixing and 87% for chloride ions which permeated the hardened cement paste specimens. This work led to the introduction of a limit of 0.15% water-soluble chlorides for reinforced concrete in many North American codes. 2.3 Service Environment In many situations, both indoors and outdoors, the service environment cannot be described with sufficient precision to determine the risk of corrosion. If the concrete will be exposed to dry conditions, controlling the chloride ion content of the concrete may be unnecessary. At the other extreme, if the concrete will be exposed , to chlorides during service, it is logical to limit the chloride contents of the ingredients to the practical minimum. However, there is a wide range of service conditions between these extremes where the risk of corrosion is not only uncertain at the time of construction, but may change during the life of the structure. 3 AGGREGATES IN SOUTHERN ONTARIO The most common high-quality aggregates used in Southern Ontario are crushed dolomites from the Amabel and Lockport formations which form the cap rocks of the Niagara Escarpment. These rocks contain unusually large concentrations of chloride ions as a result of their deposition in a saline environment on the fringes of the Michigan Basin. The acid-soluble chloride contents of aggregates supplied to the Toronto area in the 1970s from the Amabel formation were found 12 to average 0.125% (average of 25 samples) and those from the Lockport formation averaged 0.080% (average of 5 samples). The corresponding water-soluble chloride contents were 0.041% and 0.026% respectively. The chloride contents of aggregates quarried from the Amabel formation in the Collingwood area were substantially higher. For many concrete mixtures, aggregates from both formations would contribute chloride ions at a concentration above the threshold value for corrosion if all the chloride ions were available to depassivate the reinforcement. Figure 1, which has been compiled from data in a 1977 report,12 compares the acid-soluble and water-soluble chloride contents of aggregates from 24 quarries and one pit in Ontario, of which 23 sources were either dolostones or limestones. The water-soluble chlorides were extracted by grinding the rock samples to pass through a 150 jim screen and then boiling the rock powders in water for five minutes. The ratio of water-soluble to acid-soluble chloride ions ranged from 0 for a number of limestones to 75% for a beach gravel. These data illustrate clearly that the ratio of water-soluble to acid-soluble chloride contents varies considerably for individual mix ingredients. 4 LABORATORY INVESTIGATIONS 4.1 Early Screening Tests Routine testing of concrete for chloride ion content was not undertaken until Water-Soluble Chloride Ion Content, % Figure 1 Comparison of Acid-Soluble and Water-Soluble Chloride Ion Contents of Commercial Aggregates from Southern Ontario the early to mid 1970s when the problems of corrosion-induced deterioration of highway structures were first recognized. It was at this time that the high chloride content of the dolomitic limestone aggregates was first documented. A simple test was conducted in the ministry's laboratories in 1975 on a sample of aggregate from the Amabel formation using particles in the 19 to 26 mm range. The stone was immersed in distilled water for a period of 90 days and the chloride ion content of the water was measured periodically. The measured chloride content was found to be 0.003% after one day and this did not increase over the 90 day period, indicating that the likely source of the chloride ions was the exposed particle surfaces and that chloride contained within the aggregate did not enter into solution. The rock in question was porous (about 2% absorption) and the pores were of a very large size but poorly interconnected. These findings diminished concerns that the aggregate might be contributing chloride ions to the concrete pore water. In a 1982 experiment, samples of different particle sizes of the same aggregate as in the 1975 test, ranging from retained on 19 mm to passing 53 iim, were prepared and immersed in water for one week. The samples were agitated periodically. After seven days, the chloride ion content of the water was determined and the results are shown in Figure 2. As the particle size decreased, the chloride ion content increased a n d the relationship was almost linear when plotted on a log/log graph. In other words, as the rock was crushed to expose a greater surface area, the measured chloride ion content increased. This means that the measured chloride ion content Water-Soluble Chloride Ion Content, % Figure 2 Effect of Particle Size on Measured Water-Soluble Chloride Ion Content is a function of the test method, specifically the preparation of a pulverized sample, and not a measure of the quantity of chloride ions available to depassivate the steel. In a further test series conducted in 1985,13 reinforced concrete slabs were cast which contained two aggregates with chloride ion contents of 0.136% and 0.197%. Some slabs also contained various dosages of admixed calcium chloride. Microcell and macrocell corrosion rates were measured under indoor and outdoor conditions. Only the slabs containing calcium chloride at higher levels than the corrosion threshold limit exhibited corrosion. These findings were confirmed by a visual examination of the reinforcement It was recognized that, when interpreting chloride data to assess the risk of corrosion, it was necessary to correct for the background chloride content of the concrete when using aggregates with high, but 'unavailable' chloride ion contents. A practice was established by the Ontario Ministry of Transportation of taking cores from sufficiently deep within the concrete to eliminate the effect of external sources of chloride.14 The chloride content of the concrete most distant from the exposed surface is taken as the 'background' value, provided it is in agreement with the historical value, and is then subtracted from all the measured values before making comparisons with the corrosion threshold value. This approach is not valid if chloride- based admixtures have been used in the concrete. However, the presence of such admixtures is usually evident from the abnormally high chloride values which do not diminish with distance from the exposed surface. The subtraction of the background value is a pragmatic approach which has been found satisfactory over a number of years. However, a test method which measures only those chloride ions available to initiate corrosion would be preferable, and research to develop such a test method was initiated in the early 1980s. The Research was conducted at Queen's University and funded by the Ontario Ministry of Transportation. 4.2 The Soxhiet Test Method The research which led to use of the Soxhiet method for extracting chloride ions from concrete has been described in detail elsewhere. 115 The initial work involved the investigation of several hot and cold water regimes for extracting chloride ions from concrete samples and constituent materials. Tests were conducted on concretes which contained chloride-bearing aggregates, admixed calcium chloride, and chlorides resulting from vacuum saturation of hardened concrete with a 3.5% solution of sodium chloride. The results showed that the Soxhiet apparatus was capable of discriminating between chloride ions available for depassivation of the steel, and those which were unavailable by virtue of being contained in the aggregates or chemically bound in the cement paste. The Soxhiet extractor consists of a heater, a lower flask, the sample compartment, and a condenser. The extractor contains approximately 100 ml of water in the lower flask. Heat is applied to this flask and vapour from the boiling water passes to the condenser, and the condensate collects in the sample compartment. The sample, consisting of pieces of concrete not larger than 13 mm in diameter, is contained in a porous holder. When the condensate reaches a critical height, the liquid is syphoned into the lower flask and the process repeats. The non-volatile components extracted from the sample accumulate in the lower flask, while each extraction involves fresh, hot distillate. The heat input should be sufficient to give about three extraction cycles per hour. Twenty four hours is normally sufficient to remove all the extractable chloride ions. As noted elsewhere,1 the Soxhiet method of extraction was not intended to replace the acid and water extraction methods because, where chloride ion contents are low, or background levels are small, the conventional methods are quicker, less expensive, and adequate. Even where high levels are recorded, engineering approximations, combined with local knowledge, often suffice. However, where uncertainty exists, or there is a need for a discriminating procedure, the Soxhiet method is very useful. Tests conducted in connection with the development of the Soxhiet method, using water extraction on pulverized samples of concrete, confirmed the effect of particle size on the measured value of chloride ion concentration illustrated in Figure 2. Larger differences in measured values were recorded as the particles were ground finer and finer. This explains why large differences in results can be obtained from duplicate tests, where in one case the powder may be finer than the other. 5 CODE REQUIREMENTS The 1990 edition of the National Standard of Canada Can/CSA-A23.1-M90 'Concrete Materials and Methods of Concrete Construction' introduced limits for the chloride ion content of concrete ingredients, through the following clause: The water-soluble chloride ion content by mass of the cementing material in the concrete before exposure shall not exceed the following values for the indicated applications: (a) for prestressed concrete, 0.06%; (b) for reinforced concrete exposed to a moist environment or chlorides or both, 0.15%; (c) for reinforced concrete exposed to neither a moist environment nor chlorides, 1.0%. Note: These limits may be exceeded if the Owner can be satisfied that no corrosion problems have occurred in the past in concrete structures made with similar materials and exposed to similar conditions'. The clause was not changed in the 1994 edition of the standard. The test method specified (CSA Test Method A23.2-4B) involves pulverizing the material to finer than a 315 fim sieve, boiling in water for 5 minutes, followed by standing for 24 hours. As an alternative, the code permits the measurement of the acid-soluble chloride content, although the same limits apply. The note to the clause was included in recognition of the long history of the use of chloride-bearing dolomitic limestone aggregates. Unless the note were invoked by the Owner, these aggregates could not be used in prestressed concrete. Aggregates from the Amabel formation could not be used in reinforced concrete exposed to a moist environment, or chlorides, in service, unless the proportion of cementing material were higher than that used in many commercial concretes. The introduction of the clause caused controversy in the aggregate and concrete industries. While casual observation suggested that there was no difference in the long-term corrosion performance of concrete structures containing chloridebearing and chloride-free aggregates, it was decided that the time was appropriate for a systematic investigation of field structures. 6 FIELD INVESTIGATION 6.1 Experimental Design A detailed investigation was performed on a small number of bridge structures which had been in service for at least 25 years. For each structure, the corrosion performance of components which had been exposed to deicing salts during service was compared with that of components not exposed to deicing salts. In this way, the service environments of the components were as similar as possible, except for the effect of an external source of chlorides. The condition surveys of the structures included a visual inspection of the concrete surface, a delamination survey by sounding, corrosion potential measurements (according to ASTM C-876-87), rate-of-corrosion measurements (using a commercial three-electrode, linear polarization instrument), and removal of cores for determination of chloride ion content and examination of the condition of the bars. 6.2 Test Sites The field investigations were conducted on the components of three bridges built between 1959 and 1968: Sixteen-Mile Creek Bridge, Credit River Bridge, and a Structure in the Highway 403/Highway 2 interchange. The concretes contained dolomitic limestone coarse aggregate with a high chloride content. The 'background' levels of chloride ions in the concretes varied from 0.046 to 0.074% by mass, as measured by the acid-soluble extraction procedure. 6.2.1 Highway 403/Highway 2 Interchange Structure. The Highway 403/Highway 2 Interchange structure is a four-span, voided, post-tensioned slab bridge built in 1968. The 'background' concentration of chloride ions in the concrete was found to be 0.074% by mass of the concrete. Cracking and rust staining were observed on the barrier walls and sidewalks, and also on those areas of the abutments exposed to surface run-off through leaking expansion joints. All the twelve spirally reinforced columns (each with a surface area of about 10 m2) were in good condition and there was no cracking, rust staining or delamination. The columns were not exposed to surface run-off but were exposed to light splashing from the traffic. Corrosion potential measurements were taken on a 10 m2 section on the west side of the north abutment and on the six columns located at the east and west sides of the bridge. The percentages of readings falling within each of the three ranges normally associated with passive, uncertain, and active corrosion activity are given in Table 1. The potential measurements indicated that the reinforcement in the columns was passive, whereas the steel in the abutment was corroding actively. Rate-of-corrosion measurements were performed at selected locations on two of the six columns. Table 2 shows the percentages of the measurements falling within the ranges associated with insignificant, little and moderate corrosion activity.16 The readings showed that there was insignificant or little corrosion activity in the columns. Severe corrosion was observed on the bars in the two cores removed from the north abutment The average chloride content at the level of the steel (with concrete cover of 45 mm) was found to be 0.252% by mass of concrete. The anticipated Test Table 1 Corrosion Potential Measurements - Hwy. 403/Hwy. 2 Interchange Structure Corrosion Potentials (mV vs. CS\ Location >-200 -200 to -350 <-350 Abutment 0 4 96 Column 1 100 0 0 Column 2 100 0 0 Column 3 100 0 0 Column 4 100 0 0 Column 5 96 4 0 Column 6 98 2 0 Table 2 Rate of Corrosion Measurements - Hwy. 403/Hwy. 2 Interchange Structure corrosion threshold level for the concrete was approximately 0.030% plus the background contribution of 0.074% by mass of concrete. There was no corrosion on the bars in the three cores removed from the columns. The chloride content of the concrete in these cores was similar to the background chloride level of the concrete, indicating that chloride ions from deicing salts had not penetrated the concrete to any significant degree. It is recognized that the absence of corrosion on the reinforcing bars is not sufficient proof that there is no corrosion activity because the cores could have been taken from the cathodes on the bars. The lack of corrosion is presented as corroborating the data from the corrosion potential, rate-of-corrosion, and chloride measurements. 6.22 Credit River Bridge. The Credit River Bridge is a seven-span reinforced concrete arch bridge built in 1961. The 'background' concentration of chloride ions in the concrete was found to be 0.046% by mass. Concrete patches and rust staining were visible at several locations on the deck soffit and piers as a result of corrosion caused by extensive leakage through the deck joints. The portions of the piers not exposed to surface run-off were generally in good condition. Corrosion potential readings taken from 10 m2 sections on two piers and arch beams are given in Table 3. The potential readings indicated that while approximately 30 to 75% of the readings taken from the piers were within the range of active corrosion, most readings on the arches were within the passive range, and none were in the range of active corrosion. Rate-of-corrosion measurements performed at selected locations on the piers and arches are shown in Table 4. The results show that the readings taken on the arch beams were associated with insignificant or little corrosion, whereas areas on all the other faces indicated moderate corrosion. Corrosion was observed on one of the two bars removed from the piers, and the chloride content at the level of the steel (with concrete cover of 65 mm) was found to be 0.110% by mass, which exceeds the anticipated corrosion threshold value of 0.076% by mass of concrete. The bars in the two cores removed from the arches were in good condition. The chloride ion content at the level of the steel was the same as the background level. Table 3 Corrosion Potential Measurements - Credit River Bridge Table 4 Rate of Corrosion Measurements - Credit River Bridge 6.2.3 Sixteen-Mile Creek Bridge. The Sixteen-Mile Creek Bridge is a fivespan composite section steel and concrete bridge built in 1959. Each of the four piers consists of three rectangular reinforced columns. The 'background' chloride concentration in the concrete was found to be 0.072% by mass. There was spalling and rust staining on the curbs of the deck. The south face of the south column of each pier exhibited spalling, cracking, and rust staining, as a result of exposure to surface run-off through open drainage. The other columns, which were not exposed to the surface run-off, were in good condition. Corrosion potential measurements, taken from different sections of one pier, are summarized in Table 5. The area of each test section was about 13 m2, and the two test areas on the base of the pier were directly below the south face and east face of the south column. The potential measurements showed that the steel in areas exposed to the surface run-off was corroding actively, whereas none of the readings in those areas located away from the surface run-off indicated active corrosion. Rate-of-corrosion measurements from the test sections on the north column and south column are given in Table 6. The results show that the readings taken from the north column were associated with little corrosion, but almost 90% of the readings on the south column indicated moderate corrosion. Table 5 Corrosion Potential Measurements - Sixteen-Mile Creek Bridge Table 6 Rate of Corrosion Measurements - Sixteen-Mile Creek Bridge Corrosion was observed on the bar in the core removed from the south column, and the chloride content at the level of the reinforcement (with concrete cover of 40 mm) was found to be 0.215% by mass of concrete. There was no corrosion on the bars in the two cores removed from the north and central columns. The concentration of the chloride ions from de-icing salts at the level of the steel was well below the anticipated corrosion threshold level. 7 CONCLUSIONS i) ii) iii) The high concentration of water-soluble chloride ions measured in the dolomitic limestone concrete aggregates used in Southern Ontario is a function of crushing of the aggregates as required by standard test procedures. A direct relationship exists between the measured chloride content and the fineness of the aggregate particles, because of the greater surface area exposed. The Soxhlet procedure was identified as an effective method of discriminating between those aggregates which will contribute chloride ions to the concrete and depassivate embedded steel, and those in which the chloride ions remain bound within the aggregate particles. A field investigation of bridge structures, which had been in service for over 25 years, revealed corrosion only in components where deicing salts had penetrated to the reinforcement. In no case had chloride ions contained in the aggregates initiated corrosion of the reinforcement. 8 REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. D. G. Manning, 'Reflections on Steel Corrosion in Concrete', American Concrete Institute, Detroit MI, 1992, SP-131, 321. ACI Committee 222, 'Corrosion of Metals in Concrete', J. American Concrete Institute, 1985, 82, 3. K. Tuutti, 'Corrosion of Steel in Concrete', Swedish Cement and Concrete Institute, Stockholm, 1982. D. A. Hausmann, 'Steel Corrosion in Concrete', Materials Protection, November 1967, 19. V. K. Gouda, 'Corrosion and Corrosion Inhibition of Reinforcing Steel I Immersed in Alkaline Solutions', Br. Corros. 1970, 5, (9), 198. С. M. Hansson, Th. Frolund and J. B. Markussen, 'The Effect of Chloride Cation Type on the Corrosion of Steel in Concrete by Chloride Salts', Cement and Concrete Research, 1985, 15, 65. 'Standard Method of Sampling and Testing for Total Chloride Ion in Concrete and Concrete Raw Materials', Test Method T 260-84, AASHTO, Washington, D.C., 1984. D. A. Lewis, 'Some Aspects of the Corrosion of Steel in Concrete', 'Proc. of First International Congress on Metallic Corrosion', Butterworths, London, 1962, 547. К. C. Clear and R. E. Hay, Time-to-Corrosion of Reinforcing Steel in Concrete Slabs, Vol 1, Effect of Mix Design and Construction Parameters', Report No. FHWA-RD-73-32, Federal Highway Administration, Washington D.C., 1973. К. C. Clear, 'Evaluation of Portland Cement Concrete for Permanent Bridge Deck Repair', Interim Report No. FHWA-RD-74-5, Federal Highway Administration, Washington D.C., 1974. H. A. Berman, 'Determination of Chloride in Hardened Portland Cement Paste, Mortar and Concrete', Report No. FHWA-RD-72-12, Federal Highway Administration, Washington D.C., 1972. C. Rogers and G. Woda, 'The Chloride Ion Content of Concrete Aggregates from Southern Ontario', Report EM-17, Ministry of Transportation and Communications, Downsview ON, 1977. В. B. Hope and А. К. C. Ip, 'Chloride Corrosion Threshold in Concrete', Report ME-87-02, Ontario Ministry of Transportation, Downsview ON, 1987. D. G. Manning and D. H. Bye, 'Bridge Deck Rehabilitation Manual, Part One: Condition Surveys', Report SP-016, Ontario Ministry of Transportation, Downsview ON, 1984. В. B. Hope, J. A. Page and J. S. Poland, 'The Determination of the Chloride Content of Concrete', Cement and Concrete Research, 1985, 15, 863.