permeable pavements

advertisement

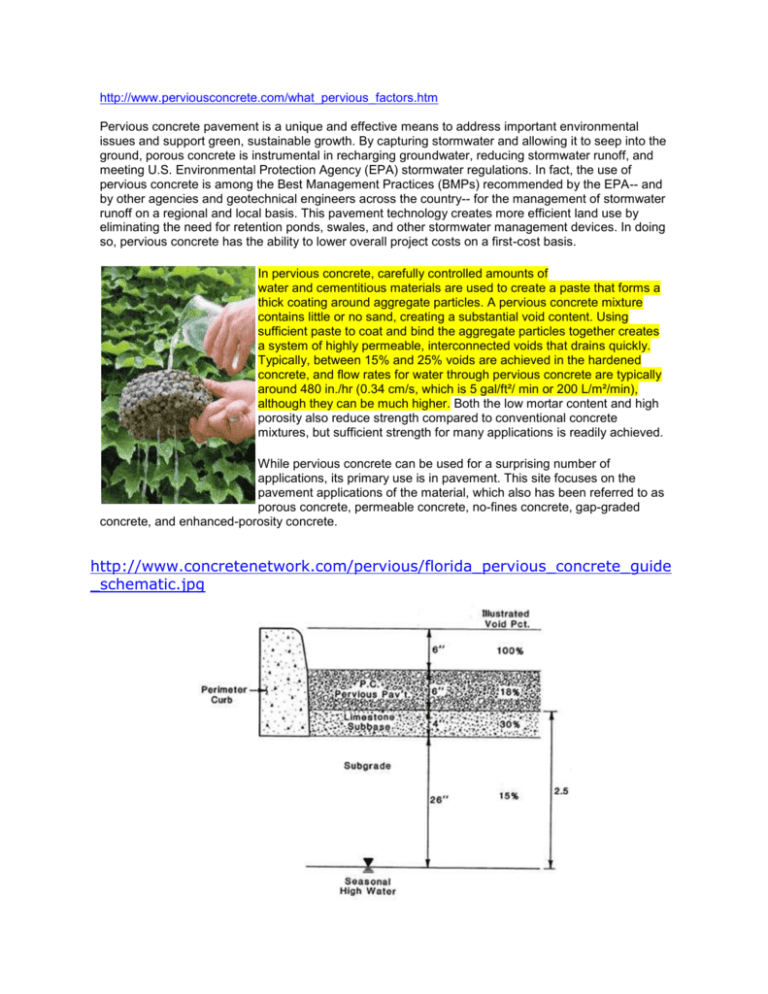

http://www.perviousconcrete.com/what_pervious_factors.htm Pervious concrete pavement is a unique and effective means to address important environmental issues and support green, sustainable growth. By capturing stormwater and allowing it to seep into the ground, porous concrete is instrumental in recharging groundwater, reducing stormwater runoff, and meeting U.S. Environmental Protection Agency (EPA) stormwater regulations. In fact, the use of pervious concrete is among the Best Management Practices (BMPs) recommended by the EPA-- and by other agencies and geotechnical engineers across the country-- for the management of stormwater runoff on a regional and local basis. This pavement technology creates more efficient land use by eliminating the need for retention ponds, swales, and other stormwater management devices. In doing so, pervious concrete has the ability to lower overall project costs on a first-cost basis. In pervious concrete, carefully controlled amounts of water and cementitious materials are used to create a paste that forms a thick coating around aggregate particles. A pervious concrete mixture contains little or no sand, creating a substantial void content. Using sufficient paste to coat and bind the aggregate particles together creates a system of highly permeable, interconnected voids that drains quickly. Typically, between 15% and 25% voids are achieved in the hardened concrete, and flow rates for water through pervious concrete are typically around 480 in./hr (0.34 cm/s, which is 5 gal/ft²/ min or 200 L/m²/min), although they can be much higher. Both the low mortar content and high porosity also reduce strength compared to conventional concrete mixtures, but sufficient strength for many applications is readily achieved. While pervious concrete can be used for a surprising number of applications, its primary use is in pavement. This site focuses on the pavement applications of the material, which also has been referred to as porous concrete, permeable concrete, no-fines concrete, gap-graded concrete, and enhanced-porosity concrete. http://www.concretenetwork.com/pervious/florida_pervious_concrete_guide _schematic.jpg Pervious Concrete Pavement is a water management system. Its bottom component is a soil base that will let water percolate through it to the aquifer below. This includes sandy and gravely soils. A layer of clay may require a system to allow water to seep through to the aquifer below which could include pipes, French drains or removing some clay. A capable site engineer's services are a valuable tool at this time. Below is a picture of a typical well draining soil. When such soil is not available, some times a crushed concrete or aggregate base is installed to store water under the pervious concrete paving. This allows the filtered water to slowly pass through the less cooperative soils by capillary seepage. Aggregate Base under Pervious Concrete being poured. In this case the aggregate prevents a build up of water in the pervious. This is extremely important during freeze-thaw conditions. For the system to function properly the correctly designed mixture must be loaded properly at the ready-mix plant, delivered promptly by a truck driver who is thoroughly trained in working with pervious ready-mix, and willing to thoroughly cooperate with the installation crew overseer. As the trucks arrive to discharge the pervious concrete, they should be accommodated by a properly leveled base set to correct elevations and thoroughly compacted. No deep ruts should be created by the truck tires. http://www.concreteincorporated.com/Portals/21/CONCEPTUAL%20DETAIL %20OF%20PERVIOUS%20CONCRETE.gif Base preparation includes testing existing undisturbed sub-soil for its ability to percolate. If the water table is at least 4 ft. below grade and septic fields work in the area, probably the permeability of the sub soil will be adequate. The base soil should be appraised by a site engineer. In a few cases this will involve taking test borings. Again we stress all organic materials such as roots, grass and trash must be thoroughly removed. Then a compactable, porous sub-base should be installed, and compacted with a vibratory compactor to a level of proctor level of approximately 92%. where sandy, compactable sub-soils are fould they may be converted into a base for pervious concrete. A properly compacted base will not be damaged by ready-mix trucks delivering the pervious concrete. If the soil is slow draining a base of crushed concrete, or other stable aggregate should be installed and compacted to a level of 95%. This is usually 6" thick or more. The Installed Base. While the engineered mixture is important there are other factors to consider such as: having a suitable base of soil, sand or crushed stone; having a drainable water table, sufficiently below the pavement is also important. Other factors are the proper preparation of an appropriate compacted, sub-base free of all organic matter, the correct concrete mixture, the designed mixing procedure, prompt placement, finishing and proper curing. Curing, really means hydration, a chemical process that requires the presence of moisture. To prevent evaporation, Pervious Concrete should be covered with polyethylene film for a week or more. The sub-base can consist of sand, crushed stone or a combination of drainable materials. If crushed stone is used the base can serve as a detention pond. Pervious concrete is usually delivered to the site in Ready Mix trucks and mixed at a specified mixing speed to result in 75 to 100 rotations of the mixing drum before discharge. After the closely controlled amount of water is added, one hour is usually the maximum time allowed for discharge. The batch must be placed, rolled, sprayed and covered quickly. This closely monitored process produces a pavement with unique characteristics. This allows it to recharge the aquifer beneath, to prevent puddles and to reduce drainage into storm sewers, streams and adjacent properties. Some of our competitors claim Pervious Concrete will allow 8 to 12 gallons per square foot per minute to pass through it. This will depend on the subbase and size and type of aggregate. Our tests with a 3/8" aggregate indicate that it will allow 3 to 10 gallons of water to pass through it per minute, compared to 2.5 to 4 gallons for Bahia grass. Larger aggregate in an appropriate mix design will drain better. In any event,1½" of rainfall, a good first flush, will represent .6234 gallons, almost five times the average three gallon minimum, if it fell within 60 seconds, an unusually heavy rainfall. How well it performs is almost always determined by what lies below it. Total percolation is mostly dependent upon base construction, aggregate size and existing soil and water table conditions. Pervious Concrete resists degradation from stress during curing. Curing is a chemical process called hydration during which molecular reactions between water and cement create a unique chemical bond which gives the Pervious Concrete unrecognized strength. Since the Pervious mixture dries with much less shrinkage than most other paving concretes, our experience has demonstrated that control joints are needed much less than with conventional concrete. Once cured it does not distort under traffic as does asphalt which often develops ruts and ripples under the hot sun, and the friction from vehicle tires. Because of its open cell structure, Pervious Concrete reduces the reflection of heat into the atmosphere. Unlike asphalt it also absorbs much less heat from the sun (50% to 75%). When it rains it does not heat the storm water runoff like asphalt, which eventually heats the bodies of water into which it is discharged. The rain water retained also cools the air above the concrete, because it acts like perspiration evaporating to cool your skin. When oil or grease drips on to pervious that same open cell structure enables volatiles to evaporate, and remaining solids to pass into the soil below, where microbial activity may consume or convert them. Because of the heavy, strong, Portland cement paste component, it forms strong molecular bonds that grow during hydration. Since most aggregate is porous it forms a mechanical bond as well and creates a pavement with greater strength and durability. If compaction by vibrating screed and rolling is not done quickly this mechanical bond will not be achieved and raveling will occur under traffic. The appropriate thickness for most pavements is 6". However thicker pavements may be designed for heavy loads. The skills of concrete engineers should be put to use in designing heavy use pavements. http://www.georgiastormwater.com/vol2/3-3-7.pdf 3.3.7.2 Pollutant Removal Capabilities As they provide for the infiltration of stormwater runoff, porous concrete systems have a high removal of both soluble and particulate pollutants, where they become trapped, absorbed or broken down in the underlying soil layers. Due to the potential for clogging, porous concrete surfaces should not be used for the removal of sediment or other coarse particulate pollutants. The following design pollutant removal rates are conservative average pollutant reduction percentages for design purposes derived from sampling data, modeling and professional judgment. Total Suspended Solids – not applicable Total Phosphorus – 50% Total Nitrogen – 65% Fecal Coliform – insufficient data Heavy Metals – 60% Pollutant removal can be improved through routine vacuum sweeping and high pressure washing, insuring a drainage time of at least 24 hours, pretreating the runoff, having organic material in the subsoil, and using clean washed aggregate (EPA, 1999). The cross-section typically consists of four layers, as shown in Figure 3.3.7-1. The aggregate reservoir can sometimes be avoided or minimized if the sub-grade is sandy and there is adequate time to infiltrate the necessary runoff volume into the sandy soil without by-passing the water quality volume. Descriptions of each of the layers is presented below: Porous Concrete Layer – The porous concrete layer consists of an open-graded concrete mixture usually ranging from depths of 2 to 4 inches depending on required bearing strength and pavement design requirements. Porous concrete can be assumed to contain 18 percent voids (porosity = 0.18) for design purposes. Thus, for example, a 4 inch thick porous concrete layer would hold 0.72 inches of rainfall. The omission of the fine aggregate provides the porosity of the porous pavement. To provide a smooth riding surface and to enhance handling and placement a coarse aggregate of 3/8 inch maximum size is normally used. Use GDOT No. 8 coarse aggregate (3/8 to No. 16) per ASTM C 33 or No. 89 coarse aggregate (3/8 to No. 50) per ASTM D 448. See the GCPA specifications (referenced). Top Filter Layer – Consists of a 0.5 inch diameter crushed stone to a depth of 1 to 2 inches. This layer serves to stabilize the porous asphalt layer. Can be combined with reservoir layer using suitable stone. Layer – The reservoir gravel base course consists of washed, bank-run gravel, 1.5 to 2.5 inches in diameter with a void space of about 40% (GADOT No.3 Stone). The depth of this layer depends on the desired storage volume, which is a function of the soil infiltration rate and void spaces, but typically ranges from two to four feet. The layer must have a minimum depth of nine inches. The layer should be designed to drain completely in 48 hours. layer should be designed to store at a minimum the water quality volume (WQ v). Aggregate contaminated with soil shall not be used. A porosity value (void space/total volume) of 0.32 should be used in calculations unless aggregate specific data exist. . Bottom Filter Layer – The surface of the subgrade should be an 6 inch layer of sand (ASTM C-33 concrete sand or GADOT Fine Aggregate Size No. 10) or a 2 inch thick layer of 0.5 inch crushed stone, and be completely flat to promote infiltration across the entire surface. This layer serves to stabilize the reservoir layer, to protect the underlying soil from compaction, and act as the interface between the reservoir layer and the filter fabric covering the underlying soil. Filter Fabric – It is very important to line the entire trench area, including the sides, with filter fabric prior to placement of the aggregate. The filter fabric serves a very important function by inhibiting soil from migrating into the reservoir layer and reducing storage capacity. Fabric should be MIRFI # 14 N or equivalent.