Stage Crew L2B Hall-MEWP Trainers Notes

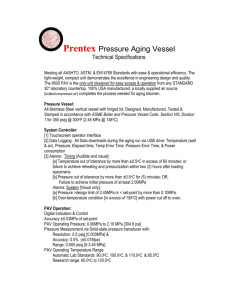

advertisement

Stage Crew L2 Hall-MEWP Trainers Notes Stage Crew Level 2 Hall-MEWP Training Trainers Notes Overview This training is aimed to make persons aware of the correct use and considerations of a simple mobile elevating work platform of the push-around-vertical type (static vertical) such as the one stored in the University Hall, as used in typical situations. Successful trainees will be able to use the hall MEWP unsupervised. Notes This training is aimed to be in-line with IPAF’s PAV course, so much so, that persons teaching this course should have a valid PAV class (or 1a with a PAV familiarisation) IPAF licence. This training is, however, aimed at the specific machine stored in the University Hall, used in 95% of likely conditions, so the training should not be assumed valid in other locations or on other machines, without an assessment by someone who is aware of this course, and who holds PAV. The working at height activities required for completion of this training are covered by the generic University of Surrey Students’ Union Working at Height risk assessment, and as such, trainees are required to read and understand it. Structure Short taught theory section Multiple-choice theory test (separate document) Practical pre-use Demonstration Practical Assessment (separate document) Theory 1 Relevant H&S Regulations o Provision & Use of Work Equipment Regulations (PUWER) 1998: Equipment must be in good working order, maintained and repaired, inspected at suitable intervals to ensure machine is safe to operate Employee must be authorised to use the equipment Employers must provide adequate training o Health & Safety at Work Act (HASWA) 1974: The employer must provide safe tools, plant and equipment T. Dyer (2011) Stage Crew L2 Hall-MEWP Trainers Notes o o The employee must not interfere with or misuse equipment provided for safety Management of Health and Safety at Work Regulations (MHSWR) 1999: Risk Assessments Competent persons Provide clear information and training to employees Therefore training must be provided, and risk assessments completed and followed o Manufacturers Manual o Only way to ensure equipment is being used properly is to follow the manual! o Safety precautions If the machine is broken – Do not use If any safety device is not functional – Do not use Machine must be level, only designed to work up and down, over its own footprint. Spirit level on machine Flooring should be checked to be solid, as machine is heavy and if broke through, could topple. Hall floor is usually ok. High voltage conductors should be avoided. None of these in the hall roof, but care should be taken with electrical items as machine is metallic All four outriggers must be deployed for the machine to lift. They can be used to level small differences Machine should not be moved while elevated Outriggers should not be adjusted or removed while elevated Do not climb on the handrails – much better to just tell the lift to get higher Platform is only rated to 113Kg. Do not exceed this. Think of extra equipment in the basket, or if you need to lift something while at height Do not attach ropes or lean objects on platform or mast, as may topple Always check area below lift before lowering, and area above lift before raising o Tech. Services WaH risk assessment o Requires persons to have completed L2 Working at Height, and specific training for the machine in use. For MEWPS this generally requires an IPAF licence – the only exception being the AWP-36 in the University Hall. o Harnesses, work positioning lanyards, high visibility jackets and hard hats are used as appropriate. Only hi-vis jackets and hard hats are appropriate in the Hall MEWP, and generally hi-vis jackets are not required as everyone is aware of the work, and visibility is good o There must be at least two persons present for any work at height o Types of MEWPs o 1a (PAV) – Static Vertical (Push Around Vertical) o 1b – Mobile Vertical (scissor lift) o 3a – Static Boom (Estates Picker) o 3b – Mobile Boom (Guilfest) 2 T. Dyer (2011) Stage Crew L2 Hall-MEWP Trainers Notes o Considerations o Weight of machine Weight is shared over the wheels and outriggers, but as the machine is in use, the weight can shift and increase in one point Floor surface must be able to take weight of machine (Hall floor seems to be fine) o Wind Not usually a problem inside, but should be considered if windy and windows are open Wind speed is measured with an anemometer. One in workshop o Side force PAV types of machines can cope with very low side loadings. So low that the AWP-36 has a side force of 0Kg. This is important if the work requires moving something at height or drilling into a wall etc. Another type of access may be more appropriate o Safety systems The machine has interlocks on the outriggers so if any one is missing, or not deployed, the lift function will be disabled Emergency stop buttons are at ground level and in the basket. They disable both lift and lower Emergency decent is at ground level. This requires no power and is hand operated Someone at ground level should be aware of how to operate the emergency stop and emergency decent, in case of emergency o Function enable For the machine to be raised or lowered from the basket, two actions are required. You must select direction and depress ‘function enable’. This helps prevent accidental operation o Familiarisation This training is only designed to cover the use of the Genie AWP-36 in the University Hall. It may be seen as relevant in other situations on similar machines, but a person holding IPAF PAV should make this assessment and ensure any extra machine familiarisation should be undertaken o Pre-use checks o The machine should be checked before each use, by each user o This is to ensure it is in safe condition, and all safety features are operational o A demonstration of this will be given o If anything is not correct, you should not use the machine, label what is wrong to alert other users, and report it to a person in charge Thorough checks o 6 monthly o As per LOLER/PUWER o Competent external person o 3 T. Dyer (2011) Stage Crew L2 Hall-MEWP Trainers Notes Theory Test The separate Theory Test should be handed out, and completed under exam conditions. The pass mark is 60% (9/15) Demonstration – Hall GENIE AWP-45 Start with machine in the ‘tipped’ position and explain how it needs to go through doorways Show how to correctly upright Correct use of outriggers Pre-use checks Walk around Thorough inspection report Cage bolts Hydraulic Fluid level (must be done while lowered due to single-sided-pressurised ram) Hydraulic Leaks Outrigger interlocks Emergency Decent Chains Synchronisation wires Practical Assessment User should demonstrate: Correct placement of machine for work (1) Correct deployment of outriggers (2) Correct levelling of machine (2) Correct use of PPE Correct use of all controls (5) Good observations (5) Marks will be deducted for each mistake as indicated by the numbers above. A pass requires fewer or equal to 11 deductions. 4 T. Dyer (2011)