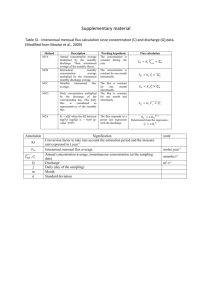

Supplementary Material_Dec2_2014

advertisement

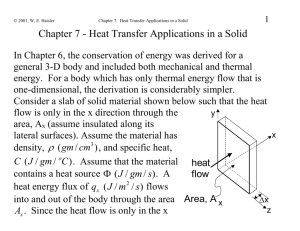

1 Supplementary Material Heat flux concentration through polymeric thermal lenses R.S. Kapadia and P.R. Bandaru Department of Mechanical Engineering, University of California, San Diego, La Jolla, CA 92093, USA Test Specimen Radiation Shield I. Temperature imaging and comparison with FEA simulations to obtain heat flux (Q) FLIR IR Camera Figure S1. Scheme for measuring temperature profiles along the surface of a thermal lens. A contactless method, employing an infrared (IR) camera (FLIR A15SC): Figure S1, was used for imaging the temperature profiles, as the typical use of RTDs (resistance temperature detectors) or heat flux sensors perturbs the heat flow. For high fidelity imaging, the images surfaces 2 were coated with a thin layer of lampblack acrylic paint (DecoArt Inc.) with an emissivity ~ 0.95. It was assumed that this layer is a reliable indicator of the temperature of the underlying polymer. Additionally, the radiative and convective losses from the other surfaces were reduced through coating of a low-emissivity (< 0.2) paint (LO/MIT-II, from Solec Energy Corp) and the use of shields placed close (< 5 mm) to the setup. The measured temperature profiles were correlated to those obtained from COMSOL, and Q was quantitatively deduced. The confidence in the obtained Q was increased through close correspondence with analytical estimates as well as through calibration by the use of simpler geometries. Additionally, the conservation of Q was always ensured, e.g., see Figure S2. The plots of Q in the figure represent the variation across four parallel and representative cross-sections corresponding to the PTL: Figure S2(a), and the CTL configurations: Figure S2(b). Figure S2. Simulated heat flux profiles along the (a) planar thermal lens (PTL), and the (b) concave thermal lens (CTL) were used for comparison with experiment and ensuring that the heat flux was conserved across various interfaces of the thermal lens. A high heat flux concentration is evident through the use of the CTL. While the computed area under the plots was constant at ~ 11.2 W/m for both the samples, the Q profiles clearly indicate the flux concentration in the CTL case. 3 II. Calibration of thermoelectric generators (TEG), used to transduce the concentrated thermal energy and heat flux (Q) to voltage Figure S3. A thermoelectric generator (TEG) used for transducing the thermal energy, obtained through heat flux focusing to electrical voltage. (a) The set up for the calibration, (b) The measured voltage as a function of the temperature difference (T) A TEG (Digikey, Laird Technologies, Model: 430701-501) was placed on a copper plate on a Peltier Cooler: Figure S1(a). Using two surface mount K-type thermocouples (precision fine wire 0.01” dia., from Omega Inc.), the temperature on the top of the TEG and the surface of the copper plate was monitored. By increasing the power to the Peltier cooler, the voltage generated was measured through a digital multimeter (Keithley 2700, cold-junction compensated) and plotted as a function of the temperature difference: Figure S3 (b). The data was fit to a slope of 14.5 mV / K, and has been used to convert the measured data of Figure 4(c) and 4(d). 4 III. Extraction of temperature values from TEG measurements and FEA simulations From the TEG measurements, the measured ratio of the temperature difference between the hot and the cold sides (ΔT) at the center and the side: ΔTcenter / ΔTside was ~ 1.43. Through comparison with FEA simulations, the equivalent ratio was found to be ~ 1.3. It was assumed that the cold side temperature was constant for all the three TEGs as they were in contact with the large conforming copper block (Figure 4 (a) and (c)). Alternately, it was noted, e.g., in Figure 4(a), that the TEGs (in the center, and the sides) were placed in contact with three nanocomposite layers, with an averaged center ~ 0.53 W/mK and side ~ 0.36 W/mK, the ratio of which is ~ 1.47.