CRITICAL HEAT FLUX

advertisement

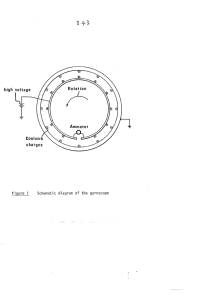

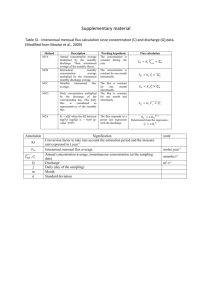

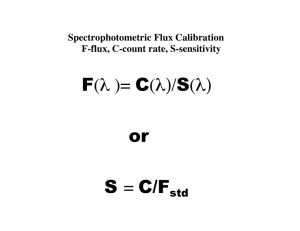

CRITICAL HEAT FLUX Lewis Kiely College of Management and Technology Introduction • What is Critical Heat Flux? • Why is it important? • What I am doing College of Management and Technology Heat Flux • Heat flow between two mediums • A metal element and water as a coolant • Water removes heat from surface • Different boiling regimes occur Single Phase Vapour Drop Flow Annular Flow with Entrainment Annular Flow Slug Flow Bubbly Flow Single Phase Liquid College of Management and Technology College of Management and Technology Critical Heat Flux and Nuclear Reactors • Reactors designed to avoid CHF • To avoid CHF, point of CHF needs to be predicted • Predicted using empirical correlations and look up tables • Correlations are not very accurate College of Management and Technology Previous Work • Heated elements in pool • Elements broke as too hot • New design: cut out from brass block • Heated surface should not melt as heat dissipates into surrounding plate. College of Management and Technology College of Management and Technology Previous Set Up • Brass block surrounded by a polythene block with flow channel • Two cartridge heaters in brass block controlled by temperature controller. College of Management and Technology Previous Set Up • Surface temperature, temperatures of the water entering and leaving the channel are recorded on a computer using a data logger College of Management and Technology 1000 900 Heat Flux (kW/m 2) 800 700 600 500 400 300 200 100 0 0 20 40 60 80 Surface temp (degC) College of Management and Technology 100 120 140 Problems With Original Design • Polythene block starts to soften and deform at ~120°C • Perspex window turns cloudy when in contact with boiling water for an extended period of time (~20mins) • Wide channel flowing into a small pipe disrupts flow of water • Channel can only be viewed from front • It leaks! College of Management and Technology New Design • Allow side view as well as front view of channel • More heat resistant materials used, allowing higher temperature - achieving Critical Heat Flux! • Larger outlet, reducing unintentional flow restriction • No more leaks! College of Management and Technology College of Management and Technology New Design-The Problems • Material chosen to replace polythene block, Tufnol, is not possible to machine on site • Machineable ceramic also investigated, but very expensive! • Channel will require more heat resistant material, such as glass College of Management and Technology Current State • Plate on brass block has been extended • End pieces of channel made • Glass for channel needs to be cut and channel formed College of Management and Technology Acknowledgements Dr Paul Chard-Tuckey - Supervisor, group manager Simon Jewer - Line manager Dr Ian Giles - UDS project manager, DE&S, Abbey Wood in Bristol Samantha Morris- Placement coordinator Terry McCarthy - Lab assistant Dr Steve Andrews - Placement tutor Jamieson Lock - Co-placement student College of Management and Technology Any Questions? College of Management and Technology