File - Andrew Wheat

advertisement

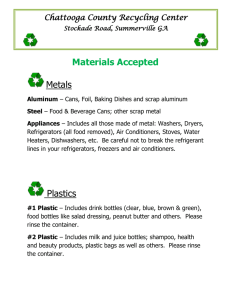

Metal Reusable vs. Plastic Water Bottles Senior Seminar By: Andrew Wheat Andrew Wheat Period 6 Plastic Water Bottles Since the existence of humans, people have tried many ways to transport water from its natural habitat. Some of the first people to do this were the Romans who invented aqueducts to carry water from its source into cities for drinking and cleaning. In small quantities, water was carried in vases, animal skin and hand woven materials. Nowadays, people have a growing need for water in personal quantities that is portable. Plastic was invented in the 19th century but was first used to replace common materials such as rubber, ivory, and shellac. The first plastic was made up of an organic matter that derived from cellulose. This matter is called celluloid and was created to replace ivory in billiards balls. Along with billiards balls this plastic is still used today as photography film. Before water was mass produced in bottles the only way to drink it was out of a glass. People wanted a way to drink it on the go. This is where the bottle became introduced. It is a durable material that could hold the water without having to worry about spilling it. Plastic water bottles were believed to be the most efficient way of packaging and selling water. Now, consumers are struggling to keep the plastic out of their homes. Plastic water bottles are made many different ways. Multi-use water bottles can be made from high-density polyethylene, low-density polyethylene, copolyester, or polypropylene. The only noticeable difference between these different types of plastic is how durable and flexible each one is. Copolyester and polypropylene bottles offer the greatest rigidity and durability. Once you have a liquid form of the plastic, Injection Stretch Blow Molding is introduced. The liquid plastic is poured into a cavity where a test tube shape is formed. Next, it is reheated and softened for step 2. In the second step, the test tube shape is filled with hot air with a lot of force causing the softened plastic to expand to the mold surrounding it. This process is known as Blow Molding. This process is most common due to the efficiency and production speed. Blow molding can produce thousands of plastic water bottles per day. One other way plastic water bottles are made is by a process called Thermo molding. In this process, plastic sheets are first heated until pliable. Then, these softened sheets are formed around a vacuum mold which sucks the plastic around the mold perfectly. There are many positives to using a plastic water bottle, but there are two sides to every story. Portability is one of the biggest reasons for the growing production of plastic water bottles. People nowadays are constantly on the go and need easy ways to stay hydrated. This is why humans don’t think twice when buying a cold water bottle from the store. Water bottles are easy to carry and easy to dispose of. Once you are done simply throw the bottle away and no longer do you have extra weight of an empty water bottle. Though the Food and Drug Administration (FDA) says that the chemicals used in plastics that make water bottles are safe, they don’t account for when the bottle is sitting in the sun under excessive heat. The longer a water bottle sits in the sun, the more chemicals seep into the water. One specific chemical called Bisphenol A mimics estrogen which has a negative health effect and can effect reproduction. When humans decide to dispose of their bottles they rarely think to recycle. They just want to get rid of the bottle causing unhealthy disposal. Littering or throwing in a normal waste receptacle is not good! Only 23% of all plastic water bottles is actually recycled. Over 38 billion water bottles are filling up landfills, and counting. In 2008 more than 2.4 billion pounds of plastic bottles were recycled. Either Recycle, Reuse, or Refuse plastic water bottles. These 3 R’s have created a movement to limit the amount of plastic that end up polluting the environment every single day. The average American consumed 1.6 gallons of bottled water in 1976. In 2006, that number jumped to 28.3 gallons. Recycled bottles provide an environmentally friendly source for making new products and replaces recycled material for new plastic. Recycled plastic bottles make hundreds of everyday products, including fleece jackets, carpeting and lumber for outdoor decking. Recycling one ton of plastics saves 7.4 cubic yards of landfill space. An island in Australia in called Christmas Island is home to one of the most polluted beaches in the world. Greta Beach accumulates hundreds of pounds of plastic pollution every week. Of all this plastic, 70% is water bottles. The reason for this pollution is failure to dispose of their waste properly. If each human consumer of bottled water recycle their bottles correctly beaches like this on Christmas island would be a lot more environmentally healthy. The water bottle industry had changed dramatically over the last decade due to the amount of pollution from plastic. Most of these changes include changes to the design of the bottle to reduce the amount of plastic used in production. Some companies have trimmed down as much plastic as possible scrapping any piece of plastic they can from their old design. These changes include making a smaller cap, thinner bottles, and smaller labels, all reducing amount of overall plastic used. In an effort to help the health of the environment, competition of plastic water bottles has increased in the last decade. Metal reusable water bottles are the biggest competition to plastic because they are the best alternative and last much longer. Along with durability they also do not effect the water in any way like plastic does. Metal bottles do not have the harmful chemicals leaking into the water such as Bisphenol A. Metal water bottles can be used for approximately four years and can substitute approximately 300 plastic water bottles per person per year. . The natural resources used to make a plastic water include oil based as well as plant based. You might not have thought that plastic ever came from a plant but it does. Although it is rare to put plant based plastic into production this form of plastic does exist. When it comes to large scale production of plastic such as water bottles you will find petroleum based plastic. They are extremely bad for the environment because most of what is produced ends up in landfills. It also isn't a very smart process since a lot of the goods made out of these plastics are containers that are used only one time, then thrown out therefore not needing the durability or shelf life that plastics have. There is a growing market for bioplastics. It is often used to describe plastics that biodegrade much faster than petroleum based plastics. These plastics are made out of things like corn and/or bagasse. Over 60 to 100 million barrels of oil are used in the producing plastic bags alone Americans purchase an estimated 29.8 billion plastic water bottles every year, of which nearly 8 out of 10 of those plastic bottles end up in landfills.