Composite Materials in 21 st Century with Prospects in

advertisement

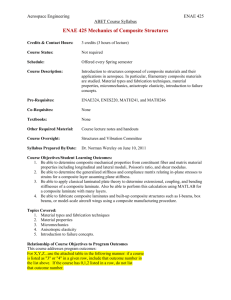

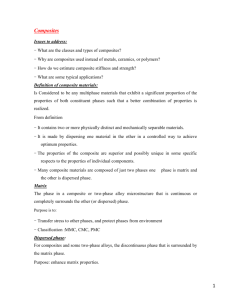

Composite Materials in 21st Century with Prospects in Nanotechnology and Digital Manufacturing A. Haque, Associate Professor Department of Aerospace Engineering & Mechanics The University of Alabama Tuscaloosa, Al-35406, USA This talk focuses progress in the field of composite materials with current practices and challenges in design, manufacturing and sustainability of composite technology. A brief history of composites and their applications in transportation vehicles, civil infrastructures, sport goods, electronics, biomedical devices, safety and protection tools and house hold appliances will be discussed. The performance of composites with traditional engineering materials will be highlighted. The commercial aspects of composite technology with future growth and prospects particularly in developing countries will be described. Recently, nanotechnology and digital manufacturing are considered to be emerging fields that are investigated for improving performance of composites and rapid manufacturing of prototype composite parts. The development of regenerated cellulose fibers using ionic liquid method are studied considering sustainability of composite technology. The reinforcing materials such as one dimensional carbon nanotube, carbon nanofiber and two dimensional graphene nanosheet and nanoclay materials are used in short fiber and continuous fiber reinforced composites for improved mechanical, thermal and electrical properties. A multiscale modeling approach using molecular dynamic simulation, peridynamics, finite element method and micromechanics based formulations are used in predicting properties of nanocomposites. The results are compared with experimental data. An improved material properties are observed in nanocomposites in comparison to neat polymers. Currently, large scale MD simulation and integrating MD simulation data dynamically to a continuum model is a challenge. Digital manufacturing such as laser sintering(LS) and fused deposition melting (FDM) show promises in manufacturing prototype composite parts using 3D printing technology. The composite filaments with micrometer and nanometer scaled reinforcing materials are manufactured for in order to use as a feedstock in FDM. The compatibility of this composite filaments are investigated in manufacturing 3D printed composite components using FDM. The properties of 3D printed materials are compared with conventional materials. The results show promises for 3D printing in manufacturing prototype composite parts. The out of plane reinforcement and scalability in 3D printing are seen to be current challenge in digital manufacturing.