The Modelling of scrubbers and AG mills - The Gibson Group

advertisement

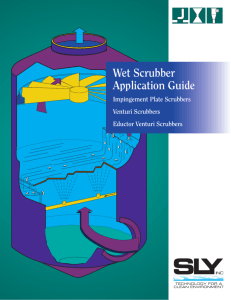

The modelling of scrubbers and AG mills. ABSTRACT The minerals industry has focused a lot of attention to the modelling of SAG mills, ball mills, crushers and HPGR’s. Less attention has been placed on the modelling of AG mills and scrubbers. This paper reviews the differences between scrubber and AG mill modelling and highlights the similarities with a view to comminution circuit design. The diamond industry is particularly exposed to the use of scrubbers and AG mills. Engineering practitioners need to be comfortable with the analysis and should not shy away from considering scrubbers for small scale copper and gold plants, treating soft oxide ores. The paper differentiates scrubber and AG mill modelling in a similar way, to which overflow ball mills and grate discharge ball mills are analysed. 500 – 1,000 kW Scrubbers suited to small scale (100-300 t/h) operations. They are not cost intensive and therefore attractive to circuit designs that require high capacity and low capex. Larger scrubbers up to 2500 kW have the capability of very high throughput in excess of 1500 t/h. KEYWORDS Modelling, scrubbers, AG mills M J. Daniel Process Consultant Citic SMCC Pty Ltd Brisbane Australia Phone: +61447550042