Final Report Draft - University of Michigan

advertisement

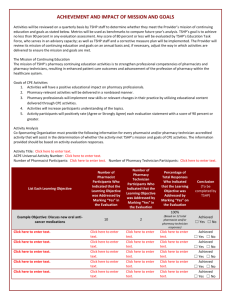

University of Michigan Health System Pharmacy Administration Department of Pharmacy Services Program and Operations Analysis Workflow Analysis of Discharge Island in Taubman Pharmacy Final Report Prepared for: Lindsey Kelley, Pharmacy Assistant Director Ambulatory Care Services, Taubman Pharmacy UH B2 D301, UMH Retail Pharmacy Shasta Branch, Staff Pharmacist UMH Taubman Pharmacy B2D400, Department of Pharmacy Services Corrie Pennington-Block, Lean Coach C.S. Mott Children’s Hospital and Von Voigtlander Women’s Hospital N14D11, CW Mott Administration Dale Jackson, POA Fellow Program and Operations Analysis 2101 Commonwealth, Suite A Dr. Mark P. Van Oyen, IOE Associate Professor Industrial and Operations Engineering 2853 IOE Prepared by: IOE 481 Project Team #4 Dylan Conlon Zachary Costello Fan Hong Amanda Lee Date: December 10th, 2013 Table of Contents Executive Summary ……………………………………………………………………. Data Collection and Analysis ….………………………………………………... Findings and Conclusions ……………………………………………………….. Recommendations ……………………………………………………………… 4 4 5 6 Introduction ……………………………………………………………………………. Background ……………………………………………………………………………. Key Issues ……………………………………………………………………………. Project Scope ……………………………………………………………………………. Data Collection …………………………………………………………………………. Takt Time ……………………………………………………………………. Phone Calls ……………………………………………………………………. Labor Analysis and Spaghetti Charts ……………………………………………. Data Analysis ...…………………………………………………………………………. Takt Time and Orders …………………………………………………………. Phone Calls ……………………………………………………………………. Labor Analysis and Spaghetti Charts ……………………………………………. Findings ……....…………………………………………………………………………. Takt Time and Orders …………………………………………………………. Phone Calls and Other Interruptions ……………………………………………. Labor Analysis and Spaghetti Charts ……………………………………………. Conclusions .......…………………………………………………………………………. Takt Time and Orders …………………………………………………………. Phone Calls and Other Interruptions …………….………………………………. Labor Analysis and Spaghetti Charts ……………………………………………. Recommendations ……..………………………………………………………………… Large-Scale ……………………………………………………………………. Small-Scale ……………………………………………………………………. Expected Impact ………………………………………………………………………... References ……………..………………………………………………………………… Appendices ………….………………………………………………………………… Appendix A ……………………………………………………………………. Appendix B ……………………………………………………………………. Appendix C ……………………………………………………………………. Appendix D ……………………………………………………………………. Appendix E ……………………………………………………………………. 7 7 8 8 8 8 9 9 9 9 10 10 10 10 12 13 15 16 16 16 17 17 18 19 20 21 21 22 24 25 26 ii List of Figures and Tables Figure 1: Incoming orders by time of day at the Discharge Island …...…………………. Figure 2: Total calls by position …………………………………………………………. Figure 3: Process time for each employee position ……………..………………………. Figure 4: Process time at each employee position with absent Filler Technician ………. 12 13 14 14 Table 1: Average order size at each island with prescription takt time …………………. 11 Order Entry Technician Spaghetti Chart ...………………………………………………. Order Entry Technician Stacked Chart ….………………………………………………. Filler Technician Spaghetti Chart ……………………………………………………..… Filler Technician Stacked Chart …………………………………………………………. Checking Pharmacist Spaghetti Chart …..………………………………………………. Checking Pharmacist Stacked Chart ……………………………………………………. Triage Pharmacist Spaghetti Chart ………………………………………………………. Triage Pharmacist Stacked Chart ...………………………………………………………. 26 27 28 29 30 31 32 33 iii EXECUTIVE SUMMARY The Taubman Outpatient Pharmacy relocated in April 2013. With the new location, the pharmacy has been experiencing long lead times, which are increasing the order backlog and decreasing employee and customer satisfaction. The purpose of this project is to provide the pharmacy with a detailed analysis of the current state and provide solutions for reducing the lead time and backlog for patient orders and increase overall employee and patient satisfaction. Employees of the pharmacy are concerned that the current layout and processes within the pharmacy are inefficient and unnecessary movement and actions of each employee are increasing backup of orders that must be completed by the end of the day. The current layout of the pharmacy includes three “Islands.” The focus of this project is the detailed operation of the Discharge Island. Once an order is received, the Order Entry Technician processes the order, sending it to a Filler Technician who retrieves the correct amount of medication from inventory. The prescription is then processed through the Checking and Triage Pharmacists, who double check the medicine through a process called “medication reconciliation.” Hour-long lunch shifts begin at staggered times for the employees, so the island is never completely vacant. Issues with backlog arise during this time. Additionally, the priorities of each prescription often contribute to backlogs and delays. For standard discharge prescriptions, priority is given to the orders for patients with the closest upcoming discharge time. Data Collection and Analysis The team’s data collection and analysis processes covered three topics: takt time, phone calls, and labor analysis. Takt Time To determine the takt time (rate of order arrivals) of each island, the pharmacy provided the team with order data for a normal Monday-to-Saturday week, totaling 679 orders, including the order size and arrival time. Information was collected for all three islands to confirm the busiest island is indeed the Discharge Island. The order arrival time and size data was stratified by island and day of the week. The student team determined the order takt times, average order size, individual prescription takt time, and total prescriptions. This data was used in conjunction with the labor analysis to compare the takt time with the process time for each employee. The takt time provided the student team with a baseline that assisted in determining process bottlenecks. Phone Calls The student team also collected data regarding employee distraction, which was largely attributed to incoming and outgoing phone calls at the Discharge Island. Phone calls were observed for arrival time, duration, employee position, incoming/outgoing, and reason. Through direct observation, the student team recorded 258 phone calls. Analysis was conducted in Excel and stratified by either day of the week, arrival time, reason for call, and/or position. The student team determined average phone call duration and the 4 percentage of each hour that is consumed with an employee on the phone, as well as which employee processes the most phone calls. These calculated values assisted the team in identifying a source of potential process waste. Labor Analysis and Spaghetti Chart The team’s observation of the pharmacy process resulted in a labor analysis and creation of spaghetti charts. Each member of the student team viewed each of the four positions at the Discharge Island (Order Entry Technician, Filler Technician, Checking Pharmacist, and Triage Pharmacist) to determine each position’s task types, task completion times, and movements throughout the workstation and environment. After 90 total hours of observation, spaced over eight weeks, the team had sufficient data for analysis. The collected data through the labor analysis of the Discharge Island’s positional tasks was stratified by position. The student team calculated the average times for each task, providing the student team with a standard completion time for each position’s commonly repeated task. These averages were used to create stacked bar charts and were synchronized with the spaghetti charts to identify the largest wastes in movement and help the team develop recommendations to ensure each position’s tasks were completed within the takt time. Findings and Conclusions The data analysis of the takt time and orders, phone calls, and labor analysis and spaghetti charts helped the team form conclusions from the data to assist in creating recommendations. Takt Time and Orders The overall takt time of the Discharge Island was calculated to be 9 minutes and 43 seconds, as compared to 9 minutes 12 seconds, and 173 minutes 20 seconds for the Non-Discharge and Transplant Islands, respectively. The Discharge Island is confirmed to be the busiest of the three islands, claimed by comparing the average order sizes with their takt time, and considering the number of prescriptions handled per day. Much of the backlog experienced can be attributed to understaffing throughout the day, with the most impact during the staggered lunch hours of the Discharge Island employees. On average, the hour between 9:30 AM and 10:30 saw the greatest influx of orders. The Transplant Island experienced the highest average order size with over 9 prescriptions per order, followed by 3.1 and 1.6 prescriptions per order from the Discharge and Non-Discharge Islands, respectively. The Discharge Island handled 165 prescriptions from 54 orders per day, whereas the other islands handled much less per day: 92 prescriptions from 57 orders at the Non-Discharge Island, and 33 prescriptions from 4 orders at the Transplant Island. Accounting for the arrival, lunch, and departure schedules, 186 orders, or 57.8% of all orders arrived when the island was understaffed. 5 Phone Calls The Discharge Island averaged 12.17 phone calls per hour. The average duration of the calls was 59.74 seconds, but varied depending on the reason of the phone call. Out of the 258 phone calls observed, 59 regarded the order status. Of the total calls that the Filler Technician, Order Entry Technician, and Triage Pharmacist handled, order status calls accounted for 37%, 25%, and 23% of all calls, respectively. Order completion phone calls accounted for 28% all calls observed. With the frequent arrival of phone calls, pharmacists were interrupted from their current work, or they worked less efficiently throughout the call. A significant portion of calls are adding zero value to the order filling process because there is no pertinent information received. Additionally, obtaining insurance information is one of the largest inhibitors of order completion. This is outside of the project’s scope, but reevaluating the check in process so the pharmacy is supplied with the required insurance information will significantly decrease the lead time, order backlog, and overall organization within the pharmacy. Labor Analysis After completing the labor analysis, the team compared each position’s average process time with the order takt time of the Discharge Island. The student team found that all four employees of the island complete their processes for each order well within the takt time of each order. However, when a staff member is absent from the Discharge Island, the staff member may be replaced by someone else within the pharmacy, but if a replacement is not available, the remaining staff on Discharge Island will have to absorb the missing staff members job duties. Therefore, the actual individual process completion time is often greater than the takt time, since the Discharge Island operates at less than full staff for several hours throughout the day. With each task defined as value-adding (necessary actions) or non-value-adding (waste within process), the student team found that the Discharge Island Process is 19.96% value-adding. Also, the spaghetti charts outline the physical movements of the employees throughout the pharmacy workspace. Overlaying each position’s spaghetti chart indicates no areas of heavy traffic, and movement for each employee remains efficient, with no extra walking or reaching evident in their movements. Recommendations After the data was collected and analyzed, the student team derived ways to reduce lead times and backlogged prescriptions. Because there are several phone calls – many of which that add zero value to completing the prescription – these phone calls need to be greatly reduced or possibly even eliminated. An easy, quick implementation would involve the installment of a ‘no order status calls policy’ throughout the hospital. This policy would eliminate 28% of the calls that require the pharmaceutical staff to postpone their required duties. Also, redistributing the job duties or adding a Rotating Technician among the staff members of the Discharge Island will reduce unevenness, and thus reduce backlog when one of the island positions is vacant. A large-scale recommendation would be the installation of an automated order database and tracking system that will monitor each order through completion. Ideally, this system will be able to notify the hospital staff who would normally be calling the pharmacy to check the order status. 6 Introduction The Taubman Outpatient Pharmacy within The University of Michigan Health System supplies prescriptions for transplant, non-discharge, and discharge patients for all three main Ann Arbor Hospitals: C.S. Mott Children’s Hospital, the University Hospital, and the Cardiovascular Center. A recent change in the pharmacy’s location has provided an opportunity to analyze the current substandard operations. A student team from the University of Michigan College of Engineering’s Industrial and Operations Department has been recruited through the IOE 481 course to analyze these operations. Specifically, the area within the pharmacy that is the designated location for discharge prescriptions, the Discharge Island, is experiencing long lead times and frequently backlogged orders, according to time studies previously performed by the student team’s lean coach. According to Taubman’s staff, pharmaceutical employees are working overtime to successfully complete the orders. To solve these issues, the Pharmacy Assistant Director has requested the IOE 481 student team to determine inefficiencies with the current layout of the pharmacy. To successfully do this, the student team determined the order takt time for all three islands within the pharmacy, performed a detailed labor analysis of the discharge island, and identified any potential waste of time or resources. Once sufficient analysis was completed, the student team formed recommendations to reduce lead time, backlogged prescriptions, and increase employee and patient satisfaction. This document discusses the methods for data collection and analysis, the findings and conclusions made from the data, and recommendations for the pharmacy to implement. Background The Taubman Outpatient Pharmacy relocated in April 2013. With the move, a new layout in the pharmacy was implemented; since the implementation of the new layout and relocation, representatives of the pharmacy have been experiencing long lead times for patient orders, which are increasing the order backlog and decreasing employee and customer satisfaction. The pressing issue to be remedied is the long lead time for each order. Employees of the pharmacy are concerned that the current layout and processes within the pharmacy are inefficient. The unnecessary movement and actions of each employee are slowing work progress, creating an increasing backup of orders that must be completed by the end of the day. The current layout of the pharmacy includes three “Islands” through which all types of prescriptions are filled. The focus of this project is the detailed operation of the Discharge Island. Currently, the process at the discharge island involves four employees: two Pharmacy Technicians and two Pharmacists. Once a prescription order is received, the Triage Pharmacist then prepares and compiles the necessary information needed, giving it to the Order Entry Technician who processes the order and sends it to a Filler Technician who retrieves the correct amount of medication from inventory. The prescription is then processed through the Checking Pharmacist, who double checks the accuracy of the filler prescriptions. At this point the order has been completed, and the patient can come to the pharmacy to receive their prescriptions. Throughout the day, the duties of each employee at the Discharge Island are shifted as they attend external meetings, address issues that arise, or leave for lunch. The hour-long lunch shifts begin at staggered times for the employees, so the island is never completely vacant. The new 7 lunch schedule was implemented in August of 2013, and has been in effect for four months. Still, issues with backlog arise during this time, especially when one of the remaining three employees must leave his or her post to address another matter, or a backup is unavailable. In addition to employee schedules and interruptions, the priorities of each prescription often contribute to backlogs and delays. For standard discharge prescriptions, priority is given to the orders for patients with the closest upcoming discharge time. For example, a patient being discharged at 11:00 am will have his or her order filled before a patient being discharged at 11:45 am. The pharmacy employees report that they are not always given enough notice to meet these time constraints. Key Issues To summarize, the main issues of concern within the pharmacy include: 1. Lengthy lead times of completing patient orders 2. Order backlog increase at busier times in the day 3. Employee dissatisfaction due to overtime hours and stressful, high-pressure situations 4. Patient complaints due to long waiting times Project Scope This project focused on improving the efficiency of the Discharge Island in the pharmacy. Information that influences the work efficiency of Discharge Island was collected and analyzed, including the pharmacy layout, the working process, responsibilities of each employee, as well as their daily schedule. The takt time and order information for all three islands within the pharmacy, however, work analysis for the Transplant Island or Non-Discharge Island are not included in the project scope. The pharmacy inventory analysis, prescription writing and anything before the orders arrive through the pneumatictube station are out of project scope as well as any process after the prescription has been filled and is ready for pickup. Data Collection With the assistance of the project coordinators, the team developed a data collection plan to reduce the lead time and backlog of orders at the Discharge Island. The plan included determining the order interarrival times (takt time) for each of the three islands in the pharmacy. Next, the team conducted a detailed labor analysis for each employee at the Discharge Island, including the creation of spaghetti charts to determine the standard movements required to complete the employee’s process. The student team began collecting data with a general observation of the pharmacy processes during normal operating hours, spanning over eight weeks for a total of 90 hours. Accuracy of the data was ensured by comparing each observer’s data against the others and looking for anomalies. Takt Time To determine the takt time of each island, the team gathered data provided by the pharmacy that included the arrival time of each order for a normal Monday-to-Saturday week, as seen in Appendix A. Also provided on these documents was the order size, or the number of prescriptions within each order. The data was supplied in several forms, including aggregated 8 charts and individual order routing slips. A total of 679 orders were included in the analysis, including 18, 339, and 322 orders from the Transplant Island, the Non-Discharge Island, and the Discharge Island, respectively. Phone Calls Because the student team was observing a fairly inconsistent process, the student team also collected data regarding pharmaceutical process “noise,” which essentially refers to employee distraction. After the student team had a sufficient overall understanding of the process, the noise was largely attributed to incoming and outgoing phone calls from the Discharge Island. After realizing phone calls are the main contributor to distraction, phone calls were recorded for the following attributes: arrival time, duration, employee position, incoming/outgoing, and reason. In total, 258 phone calls were recorded through direct observation by all members of the student team. Labor Analysis and Spaghetti Charts Observation of the pharmacy process resulted in the student team performing a labor analysis and creating spaghetti charts. To understand the overall workflow of the pharmacy, the team observed each hour of the day (9am-6pm) at least twice, as well as observing for some time on each day of the week (Monday-Friday) at least twice. This coverage gave the team a complete view of the pharmacy operations and how the process may change throughout the day and week. Also, each member of the student team viewed each of the four positions at the Discharge Island (Order Entry Technician, Filler Technician, Checking Pharmacist, and Triage Pharmacist) to determine each position’s task types, task completion times, and movements throughout the workstation and pharmacy environment. After 90 total hours of observation, spaced over eight weeks, the team had sufficient data for analysis. Data Analysis To analyze the data collected through on-site observation, the student team conducted a takt time analysis, a phone call analysis, a labor analysis, extracting data from observations and spaghetti charts. All members of the student team compiled their data in a clean, non-aggregated form (for easier manipulation) within Microsoft Excel. Once collected, each team member’s data was compared to the others’ data to identify discrepancies or statistical outliers. If any such measurements were found, they were eliminated from the final analysis. Takt Time and Orders Microsoft Excel was used to perform the takt time and order analysis. The data (supplied by the pharmacy) regarding order arrival times was stratified by island and day of the week. The student team utilized the embedded Excel functions to determine the following: Patient order takt times Average prescriptions per patient order Individual prescription takt time Total prescriptions handled This data was used in conjunction with the labor analysis to compare the takt time with the process time for each employee. The takt time provided the student team with a baseline that 9 assisted in determining process bottlenecks. More information on the data collected regarding takt time can be found in Appendix A. Phone Calls Phone call analysis was conducted in Excel and stratified by either day of the week, arrival time, reason for call, and the position within the Island that handled the call. The reason of the phone calls was separated into one of the 8 categories that were established by the student team, found in Appendix B. Using embedded Excel functions, the student team determined a variety of averages and percentages integral for developing recommendations. Most importantly, the percentage of each hour that is consumed with an employee on the phone, which employee position processed the most phone calls, and the most prevalent phone call reasons were determined. These calculated values helped the team in identifying sources of process waste. Labor Analysis and Spaghetti Charts Deriving information from the labor analysis and spaghetti charts was completed through Microsoft Excel. The collected data through the labor analysis of the Discharge Island’s positional tasks was entered into a spreadsheet, stratified by employee position at the island. The student team used embedded Excel functions to calculate the average times for each task. These averages provided the student team with a standard completion time for each position’s commonly repeated task, and were used to create stacked bar charts, creating a visual representation of each position’s time allocation. The stacked bar charts were synchronized with the spaghetti charts to identify the largest wastes in movement. The student team plotted the stacked charts against the takt times for the Discharge Island allowing the team to develop recommendations to eliminate process unevenness, and ensure all process times remain less than the takt time. Also, the student team analyzed each position using the spaghetti charts to find any movement wastes or heavy traffic areas within the pharmacy. The layout of the pharmacy in Appendix C, supplied by the pharmacy employees, was used to create the spaghetti charts. Findings This section covers the findings from the data analyzed using the methods previously described. Included are the results of the takt time and order analysis, the phone call analysis, and the labor analysis. The main points explain that the Discharge Island handles 165 prescriptions per day, more than the other two Islands. Also, most of the phone calls observed are either order status or order completion calls. The labor analysis shows the Filler Technician processes are the most time-consuming, while the Triage Pharmacist processes are the least time-consuming. Takt Time and Orders The full takt time and order analysis results can be found in Appendix A. The overall takt time of the Discharge Island was calculated to be 9 minutes and 43 seconds, as compared to 9 minutes 12 seconds, and 173 minutes 20 seconds for the Non-Discharge and transplant islands, respectively. The Transplant Island experienced the highest average order size with over 9 prescriptions per order. This large order size is countered by the long takt time of the Transplant Island compared to the other islands. The project clients had previously indicated that the Discharge Island was the location of the pharmacy with the largest workload, however no previous analysis was 10 conducted to confirm this. The student team collected order information for all three islands to confirm the busiest island is indeed the Discharge Island, supported by data seen in Table 1. Table 1 below shows the average order size for each island, and how it compares to the takt time, achieving a new metric: the prescription takt time, which is a better indicator of workload. Table 1: Average order size at each island with prescription takt time Island # Rx per Day (SD) Order Takt Time Order Size # Rx (SD) Rx Takt Time Transplant 27.33 (20.0) 173 min 20 s 9.11 (8.7) 19 min 2 s Non-Discharge 92 (23.2) 9 min 12 s 1.63 (1.2) 5 min 39 s Discharge 165 (58.6) 9 min 41 s 3.07 (3.0) 3 min 9 s Data collected 10/21/2013 – 11/9/2013 (n = 679 orders) The Discharge Island handles the most prescriptions per day. As seen in the table above, the average order size and order takt time can be used to calculate the prescription takt time. The prescription takt time can be used as a more specific indicator of differences in average workload between the islands. Similarly, the number of prescriptions handled per day provides insight into the workload at each island. Through the observed Monday - Saturday period, the Discharge Island handled 165 prescriptions from 54 orders on a daily basis, whereas the other islands handled much fewer per day: 92 prescriptions from 57 orders at the Non-Discharge Island, and 33 prescriptions from 4 orders at the Transplant Island. By stratifying the orders by day of the week, most orders arrive at the Discharge Island on Thursday and Friday. The busiest recorded day, Thursday, saw 64 orders, resulting in a takt time of 8 minutes 26 seconds, whereas the lightest day, Monday, only saw 45 orders, resulting in a takt time of 12 minutes. Separating all orders by time of day, the hour between 9:30 AM and 10:30 saw the greatest influx of orders, averaging over 9 orders at this time each day. This hour span is the peak time of order arrivals at the Discharge Island; orders throughout the rest of the day steadily decline until the close of the pharmacy at 6 PM. This data is shown in Figure 1 below. 11 Incoming Orders 6 5 4 3 2 1 8 - 830 830 - 9 9 - 930 930 - 10 10 - 1030 1030 - 11 11 - 1130 1130 - 12 12 - 1230 1230 - 13 13 - 1330 1330 - 14 14 - 1430 1430 - 15 15 - 1530 1530 - 16 16 - 1630 1630 - 17 17 - 1730 1730 - 18 18 - 1830 1830 - 1900 0 Time of Day Data collected 10/21/2013 – 11/9/2013 (n = 679 orders) Figure 1: Incoming orders by time of day at the Discharge Island Most orders arrive between 9:30 AM and 10:30 AM. Figure 1 above shows that many orders arrive before 10:00 AM, when the island first becomes fully staffed. The number of orders diminishes throughout the day, with no orders arriving after 6:00 PM when the Pharmacy Closes. Additionally, knowing the arrival, lunch, and departure schedules of both the pharmacists and technicians at the Discharge Island, the team found that 186 orders, or 57.8% of all orders within the observed week arrived when the island was understaffed. Understaffing happens early in the morning before all workers arrive, midday when the workers take staggered lunch breaks, or in the evening when some workers leave before others. A detailed daily schedule for each position can be found in Appendix D. It is important to note that employees from other islands within the pharmacy are sometimes available to cover for the vacant Discharge Island employee when there are several orders not ready in time. However, as seen through the general observation time, a replacement is often not available, and the position will remain vacant throughout the scheduled time. Phone Calls and Other Interruptions There was 12.17 phone calls per hour, which includes both incoming and outgoing calls. The average duration of the calls was 59.74 seconds, but varied dependent on the reason of the phone call. This data can be found in Appendix B. When taking a short-duration call, where the employee would spend less than 1 minute on the phone, the employee would stop his or her current task to complete the call before resuming the current task. However, when answering a call that lasted 3 or more minutes, the employee continued working on the tasks at hand while on the phone. The type and duration of phone calls vary by position, with each employee handling en unequal percentage of all phone calls. This data is shown in Figure 2 below. 12 Data collected 10/1/2013 – 11/7/2013 (n = 258 calls) Figure 2: Total Calls by Position The Filler Technician handles the majority of all phone calls at the Discharge Island. As Figure 2 shows, the Filler Technician handles nearly half of all phone calls at the Discharge Island. The Order Entry Technician and Triage Pharmacist handle nearly 1 quarter of calls each, with the Checking Pharmacist handling the least phone calls at 10 percent. A significant portion of the phone calls in the pharmacy are people calling in to receive a status on their order. Out of the 258 phone calls observed, 59 of these were about the order status. Of the total calls that the filler technician, order entry technician, and triage pharmacist handle, 37%, 25%, and 23% are order status calls, respectively. Another potential source of wasted time was the pharmaceutical staff – specifically the filler technician and triage pharmacist – calling the designated department to notify the staff that the patient’s order is complete. These order completion calls account for 28% of all phone calls at the Discharge Island. A more detailed breakdown of the phone calls can be found in Appendix B. In addition to phone call distraction, pharmaceutical staff in Discharge Island are sometimes interrupted by the need to complete social work, which entails contacting doctors, insurance companies, or other departments in the hospital to check the insurance information on the patients’ cases to discharge the patient. Social work and other insurance-related tasks range in duration from 5 minutes to several hours or, on occasion, across several days. Labor Analysis and Spaghetti Charts Upon the completion of the labor analysis, the team compared each position’s average process time with the order takt time of the Discharge Island. The student team found that all four employees of the island complete their individual processes for each order well within the takt time of each order. This claim is expressed in Figure 3 below. 13 Total Time (Full Strength) Data collected 10/31/2013 – 11/7/2013 Figure 3: Process time for each employee position At full strength, all employees complete their position’s tasks within the order takt time. As seen in Figure 3, each position’s tasks are completed in less time than the orders arrive, which is represented by the red dashed line at the top of the graph. However, the situation in the chart above is for a fully staffed island. During lunch time at the Discharge Island, employees stagger their 1-hour breaks from 12:00 noon to 3:30 PM. A full lunch break schedule can be seen in Appendix D. If little to no pending orders were at the Discharge Island, one or more remaining technicians or pharmacists would absorb the duties of the absent technician or pharmacist. If several pending orders were at the Island, a technician or pharmacist from another island would temporarily move to the Discharge Island, and take over the duties for the absent worker. If one or more positions are vacant at the island, the total process time for each employee will increase with the added duties of the absent worker. For example, when the Filler Technician is absent, their duties will be shared between the Order Entry Technician, the Checking Pharmacist, and the Triage Pharmacist. A visual representation of this situation is shown in Figure 4 below. Here, the total process time of the Checking Pharmacist is above the takt time, indicating a backup is likely to occur at that position, further delaying orders and increasing order lead time. 14 Total Time (Without Filler Technician) Data collected 10/31/2013 – 11/7/2013 Figure 4: Process time at each employee position with absent Filler Technician With the Filler Technician absent, tasks are distributed to the remaining employees. Additionally, the process time stacked bar charts for each employee can be found in Appendix E. Each stack is separated by task, positioned in order, first task on the bottom, and final task on top. Each task is defined as value-adding (VA), non-value adding (NVA), or semi-value-adding (SVA). These terms indicate whether or not the process adds value to the product (the patient order’s prescriptions). Overall, the Discharge Island Process is 19.96% value-adding. Another result of the labor analysis comes from the linking of the spaghetti charts for each position to the task list and process times. A spaghetti chart, task list, and process time chart for each position can be found in Appendix E. The spaghetti charts outline the physical movements of the employees throughout the pharmacy workspace. These can be used to find areas of the pharmacy with heavy traffic, where one employee’s movements may interfere with another’s movements. Fortunately, overlaying each position’s spaghetti chart indicates no areas of heavy traffic, and movement for each employee remains efficient, with no extra walks or reaches evident in their movements. Conclusions This section covers the conclusions derived from all data analysis methods considering the findings from labor analysis, phone call analysis, and takt time analysis. Overall, the Discharge Island is confirmed to be the busiest island, handling the most prescriptions per day. Phone calls are the largest source of distraction for all employees. The labor analysis indicates that most backlog is attributed to vacancies throughout the day at the Discharge Island. 15 Takt Time and Orders: The Discharge Island is the busiest Island Despite the takt time from the Non-Discharge Island being shorter than that of the Discharge Island, the Discharge Island is confirmed to be the busiest of the three islands. This claim was made by comparing the average order sizes of the three islands with their takt time, and considering the number of prescriptions handled per day. Also, the time of day when most orders arrive (9:30-10:30 AM) is before lunch, and nearly 60% of daily orders arrive during times when one or more positions at the Discharge Island is vacant. Therefore, much of the observed order backlog can be attributed to understaffing. Understaffing means that all tasks normally distributed between four employees are now covered by only two or three workers, which can cause long order lead times and backlog, especially on the busiest days of the week, Thursday and Friday. Phone Calls and Other Interruptions: Phone calls are the largest source of distraction Per hour, 12.17 phone calls are handled by the discharge Island, averaging 56.82 seconds per call. With the arrival of phone calls, pharmacists were interrupted from their current work, or they worked less efficiently. Some of these phone calls provide the staff with a piece of valuable information (i.e. insurance information, order specifications, etc.), but a significant portion of these calls are adding zero value to the order filling process. Additionally noticed through observation, obtaining insurance information is one of the largest inhibitors of order completion. This is outside of the project’s scope, but reevaluating the checkin process so the pharmacy is supplied with the required insurance information will significantly decrease the lead time, order backlog, and overall organization within the pharmacy. Labor Analysis and Spaghetti Charts: Backlog forms from vacancies at the Discharge Island As seen in the Figure 3 above, each position’s tasks for each order are completed in less time than the orders arrive. That is, the backlog and long lead times are not a product of the workflow within the fully-staffed Discharge Island, rather from times of the day when the island is not fully-staffed, or from out-of-scope issues, such as insurance or social work. Since the schedule in Appendix D indicates that the Discharge Island is not fully staffed for over half of the day, issues with backlog and long lead times can arise from tasks not being evenly distributed among the remaining employees. Between three and five times per day, a high priority order arrives at the Discharge Island. When this order reaches them, each of the pharmacists and technicians in the Discharge Island would stop their current work to begin handling the high priority order. When an order with a compound prescription arrived, extra time was taken for the filler pharmacist to repeat walking between the inventory and the island and again to fill the complex prescription. Some of other special cases occurred within the order entry portions of the Discharge Island process, such as prior authorization, insurance check, and social work, which increased the lead time even though the prescription was already filled. 16 Recommendations Based on the results of the student team’s general observation and data collection and analysis, recommendations have been formulated to help the Taubman Outpatient Pharmacy reduce lead time and order backlog. Both a large-scale change recommendation and several small-scale recommendations were developed, giving the pharmacy options to consider with varying costs, implementation times, and expected impacts. Large-Scale Recommendation: Order database with tracking system A sustainable, yet costly and difficult-to-implement solution would be the installation of a tracking system that will monitor the order for completeness. Ideally, this system will notify the patient’s care provider, which includes nurses, doctors, clerks or anyone calling the pharmacy to check the order status. The goal of this system is to eliminate all order status calls, as well as the order completion calls placed when the order is ready for pickup, which make up 56.1% of the total calls. This system will assign a tracking number to each order that the nurses from the hospital floor will be able to access throughout the order’s time within the pharmacy. At each step, the employee will use one of the computers (or portable tablet) to “check-in” the order at their position, which will update the status of the order across the entire database. The order will be checked in at the following points: 1. At the point of order retrieval from the pneumatic tube station A worker will enter the number into the system or scan a barcode. This order will enter the “current orders” queue, where it will remain until it is completed This process will replace the current A.C.P. log at the Discharge Island, and create a searchable, editable, and permanent database of orders The order record will still have the same information, including the arrival time, discharge time, and number of prescriptions 2. At the beginning of order entry The Order Entry Technician will indicate that the technician has begun the order entry work 3. At the beginning of the filling process Once the Filler Technician receives the order to begin filling, the technician will update the status of the order 4. At the beginning of the checking process The Checking Pharmacist will indicate that the order has begun the checking process 5. At the completion stage of the order, when it is ready for pickup Upon indicating that the order is complete and ready to be picked up, a worker at the pharmacy will enter the co-pay information, which will be included in the relay message to the corresponding floor of the hospital where the patient is located 17 6. At order pick-up Once the patient has picked up and paid for their order, the order will be removed from the “current orders” queue, where it will be stored in the permanent database. As Alexis Garrobo indicated in the article from the Tribune Business News, having a tracking system gives an “element of control” to the viewers of the tracking system, which in this case are the care providers. Many of the order status calls are to see if the order was received by the pharmacy, so implementing a tracking system allows the care providers to immediately check whether the placed order was indeed received. Letting the nurses know the status of all orders they may be concerned with will allow them to “...monitor the changes instead of waiting to be notified” [1]. Small-Scale Recommendations The large amount of phone calls, many of which add zero value towards completing the prescription, needs to be greatly reduced or possibly even eliminated. One way to reduce the order status calls is to simply educate the care providers on how the process within the pharmacy works. Another option involves the installment of a ‘no order status calls policy’. This policy would eliminate 28% of the order status calls that require the pharmaceutical staff to postpone their required duties. To counter the increased job process time when the Discharge Island is not operating at full staff, the Filler Technician tasks should be more evenly distributed between the Triage and Checking Pharmacists. Specifically, designating the “Receive/Log Order” task to the Triage Pharmacist will make the job requirements more evenly distributed. Assigning the Triage Pharmacist as the primary phone call handler will also make the job requirements more evenly distributed. Currently, when the Filler Technician goes to lunch, the Checking Pharmacist takes over the roles of filling orders in addition to checking them immediately afterwards. This method reduces the effectiveness of a different employee performing the checking of the prescriptions. As a result, the student team recommends that one pharmacist, either the Checking or Triage Pharmacist, fill the order, and the other pharmacist checks the orders. The leveling of tasks would result in an average takt time of 6.1 minutes per position, which is significantly less than the current 9.7 average takt time. Even with potential positional vacancies, the average job task time per position would be 8.15 minutes with one vacancy and 12.23 minutes with two vacancies. These times show that leveling of duties will speed up the entire order completion process. Because the Discharge Island is operating at less than full capacity for 56% of the day, adding a rotational Technician would reduce the number of understaffed hours, which will greatly reduce prescription backlog. Most importantly, the rotating technician would be present at the Discharge Island during lunch breaks (12:00 – 2:00 pm) effectively eliminating the two hours of understaffing at the Filler Technician and Order Entry Technician positions, which have the longest processing time. 18 Expected Impact The recommendations will improve the overall flow of orders at the Discharge Island. The backlog and lengthy lead times of the orders are also expected to decrease, or possibly be eliminated. The workload of each pharmacist in Discharge Island will be balanced, which will also lead to less high-pressure situations. With reduced backlog, the work left for the next day will be reduced and the daily work will become better organized. The environment of pharmacy will become more harmonious which will make the employees and patients feel more comfortable, and increase overall satisfaction. 19 References [1] Garrobo, A. (2008, Feb 10). Hospital gets patient tracking system. McClatchy – Tribune Business News. Available: http://search.proquest.com.proxy.lib.umich.edu/docview/465936886?accountid=14667 20 Appendix A: Takt/Order Time Analysis Orders received: Collected 10/21/2013 – 11/9/2013 (n = 679 orders) NonTransplant Discharge Discharge Monday 2 55 45 Tuesday 1 71 57 Wednesday 6 67 54 Thursday 4 59 64 Friday 5 66 61 Saturday 0 21 41 TOTAL 18 339 322 Before 9 9-10 10-11 11-12 12-1 1-2 2-3 3-4 4-5 5-6 After 6 NonTransplant Discharge Discharge 2 8 33 0 47 53 2 44 40 2 38 49 3 41 30 3 34 28 2 30 34 3 34 33 1 30 15 0 23 7 0 10 0 Takt Time (Min) Orders Per Hour Order Size Rx Takt Time Rx Per Hour Takt Time NonTransplant Discharge Discharge 173.33 9.20 9.69 0.35 6.52 6.19 9.11 1.63 3.07 19.02 5.65 3.15 3.15 10.62 19.04 173m 20s 9m 12.21s 9m 41.37s 679 Discharge, average per day 5.50 8.83 6.67 8.17 5.00 4.67 5.67 5.50 3.00 1.40 0 21 Appendix B: Phone Call Analysis Phone Calls: Collected 10/1/2013 – 11/7/2013 (n = 258 calls) Phone Calls by Position Position Checking Pharmacist Filler Technician Order Entry Technician Triage Pharmacist Total Calls 25 115 63 55 Average Duration (s) 74.11 56.16 60.15 48.53 In Out Percentage 9 58 36 26 14 38 14 23 9.69 44.57 24.42 21.32 Time on Phone Per Order 11.38 52.35 28.68 25.04 Phone Calls by Reason Reasons Cancellation Order Completion Insurance No Answer Order Change Order Status Page Response Question Total In 1 1 59 0 21 8 2 9 9 9 59 57 3 3 56 43 Out 0 58 13 1 0 2 0 13 CP % 0.00 16.95 4.76 0.00 0.00 1.69 33.33 12.50 FT % OE % 100.00 0.00 47.46 1.69 38.10 52.38 0.00 100.00 22.22 55.56 59.32 20.34 33.33 0.00 33.93 30.36 TP % 0.00 33.90 4.76 0.00 22.22 18.64 33.33 23.21 Average Duration 150.00 23.96 117.71 17.50 81.00 47.71 40.00 67.21 Phone Call Reason by Position and Reason Reasons Cancellation Order Completion Insurance No Answer Order Change Order Status Page Response Question CP (s) 0.00 50.00 5.00 0.00 0.00 5.00 5.00 35.00 FT (s) 1.06 29.79 8.51 0.00 2.13 37.23 1.06 20.21 OE (s) 0.00 2.08 22.92 4.17 10.42 25.00 0.00 35.42 TP (s) 0.00 41.67 2.08 0.00 4.17 22.92 2.08 27.08 22 Appendix B: Phone Call Analysis (continued) Phone Calls by Position without ‘Order Status’ Calls Position Total Calls CP FT OE TP 24 80 51 44 Average Duration 76 57.55 65.73 49.30 In Out Percentage 9 24 24 15 13 37 14 23 12.06 40.20 25.63 22.11 Time on Phone/order 11.89 39.65 25.27 21.81 Calls recorded by time of day Call Start times Calls Recorded 9:00 - 12:00 97 12:01 - 3:00 65 3:01 - 6:00 39 23 C: Pharmacy Layout 24 D: Pharmacy Staffing Schedule Time 8:00 AM 8:30 AM 9:00 AM 9:30 AM 10:00 AM 10:30 AM 11:00 AM 11:30 AM 12:00 PM 12:30 PM 1:00 PM 1:30 PM 2:00 PM 2:30 PM 3:00 PM 3:30 PM 4:00 PM 4:30 PM 5:00 PM 5:30 PM 6:00 PM 6:30 PM Average Patient Average Orders Prescriptions Triage Order Checking Received per Received per Pharm. Entry Tech. Filler Tech. Pharm. day day 2.50 14.83 3.00 9.33 Arrive Arrive 3.67 9.83 5.17 14.83 Arrive Arrive 4.00 9.17 2.67 6.33 4.00 12.33 4.17 10.33 Lunch 2.00 10.00 Lunch Lunch 3.00 5.67 Lunch Lunch 2.17 8.67 Lunch 2.50 11.50 3.67 11.00 Lunch 2.00 6.00 Lunch 3.83 13.33 1.67 2.67 1.67 2.17 0.83 1.50 Leave 0.83 4.00 0.33 1.50 Leave 0.00 0.00 Leave 0.00 0.00 25 Appendix E: Labor Analysis (Spaghetti Charts, Detailed Job Elements, Stacked Charts) Order Entry Technician Spaghetti Chart: 26 Appendix E: Labor Analysis (continued) Order Entry Technician Detailed Job Elements: 1. Data Entry a. Fill out required data fields in computer software from data on orders *If there is missing insurance information then proceed to 2. *If there is missing information for a drug, proceed to 4b. 2. Third-party communication a. Alphanumeric page to UMHS affiliates for no insurance, prior authorization, or prescription edits b. Call insurance companies if insurance is rejected c. Instant message social work (guest assistance) 3. Printing and Script Arrangement a. Prints prescription labels b. Folds labels and prescription c. Places in basket 4. Walking (4s) a. Delivers completed order to filler technician. Typically, the order entry technician will place the basket on top of the order tech’s desk, but if information needs to be conveyed to the filler technician then they will walk to the filler technician and deliver the order as well as any other necessary information. b. Retrieves drug from inventory if NDC is not known 5. Phone Calls a. Responses to alphanumeric pages b. Discusses order information with care provider Order Entry Technician Stacked Chart: 600 500 ⑤ Phone Calls (NVA) 400 ④ ⑤ ③ ② 300 200 ④ Walking (NVA) ③ Printing/script arrangement (NVA) ① ② Third party communication (SVA) ① Data Entry (SVA) 100 0 Order Entry Technician 27 Appendix E: Labor Analysis (continued) Filler Technician Spaghetti Chart: 28 Appendix E: Labor Analysis (continued) Filler Technician Detailed Job Elements: 1. Walk to tube station (11s) 2. Receive/log order a. Open tube and extract contents b. Time stamp contents 3. Walk to Island (11s) a. Enter order information into handwritten log 4. Set workstation a. Select appropriate container b. Match container with each prescription c. Prepare labels for application 5. Walk through inventory shelves to retrieve items (27.8s) Each prescription is in a different location within the inventory shelves. The Filler Technician will only walk to the appropriate locations. 6. Fill prescriptions a. Measure correct drug amount b. Fill and seal containers c. Apply container labels d. Pass to Checking Pharmacist 7. Phone calls a. Answer incoming order status and question calls b. Make order completion calls Filler Technician Stacked Chart: 600 ⑦ 500 ⑦ Phone Calls (NVA) 400 ⑥ ⑥ Fill Prescriptions (VA) 300 ⑤ Walk to inventory (NVA) ④ Set Workstation (NVA) 200 100 0 ⑤ ③ Walk to island (NVA) ④ ② Receive/Log Order (SVA) ③ ① ② Filler Technician 29 Appendix E: Labor Analysis (continued) Checking Pharmacist Spaghetti Chart: 30 Appendix E: Labor Analysis (continued) Checking Pharmacist Detailed Job Elements: 0. Receive order materials from Filler Technician 1. Walk to computer (3.4s) 2. Walk to Island (3.4s) Repetitions of walking between computer and island workspace happen normally once for each prescription in the order. 3. Check prescriptions a. Check the prescriptions in the basket for accuracy If an issue arises, consult with Triage Pharmacist, proceed to step 4. b. Pack the items into pick-up bag c. Deposit bag into center of island, ready for pick-up 4. Walk to Triage (3.5s) This walk occurs only when an issue with an order arises, where the Checking Pharmacist consults the Triage Pharmacist, who may contact the patient’s care provider. 5. Walk to front desk (5.4s) This walk occurs only when the patient receiving the order is waiting in the lobby, and the order must be placed behind the front desk for pickup. 6. Phone calls Checking Pharmacist Stacked Chart: 600 500 400 ⑥ Phone Calls (NVA) ⑥ 300 ⑤ ④ ⑤ Walk to front desk (NVA) ④ Walk to triage (NVA) ③ Check Prescriptions (SVA) ② Walk to island (NVA) 200 ① Walk to computer (NVA) ③ 100 ② 0 ① Checking Pharmacist 31 Appendix E: Labor Analysis (continued) Triage Pharmacist Spaghetti Chart: 32 Appendix E: Labor Analysis (continued) Triage Pharmacist Detailed Job Elements: 1. Printing a. Pull up and check order prescription information - “digis” b. Print digis 2. Walk to printer (6s) 3. Walk to Island (6s) a. Order and paperclip materials 4. Walk to Order Entry (4.4s) a. Deposit materials 5. Phone Calls a. Out to patient’s care provider to solve issued found by Checking Pharmacist Triage Pharmacist Stacked Chart: 600 500 400 ⑤ Phone Calls (NVA) ④ Walk to order entry (NVA) 300 ③ Walk to island (NVA) ② Walk to printer (NVA) ① Print (NVA) 200 ④ ⑤ 100 ③ ② ① 0 Triage Pharmacist 33