machine j

advertisement

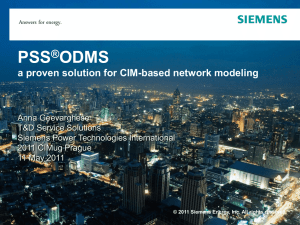

GENERATOR MODELS A) Generator Data for Round Rotor Units (GENROU):S.No Parameter Description Symbol as per PSSE 1 5 6 d-axis open circuit transient time constant (s) d-axis open circuit sub-transient time constant (s) q-axis open circuit transient time constant (s) q-axis open circuit sub-transient time constant (s) Inertia (MW.s/MVA) Speed damping (pu) H, Inertia D, Speed Damping 7 d-axis synchronous reactance (pu) Xd 8 9 10 q-axis synchronous reactance (pu) d-axis transient reactance (pu) q-axis transient reactance (pu) X'q Xq X'd X'q 11 12 sub-transient reactance (pu) X''d = X''q Leakage reactance (pu) X''d = X''q Xl 13 14 Saturation factor at 1.0 pu voltage Saturation factor at 1.2 pu voltage S(1.0) S(1.2) 2 3 4 T'do (> 0) T''do (> 0) T'qo (> 0) T''qo (> 0) PSS®E 33.5 Generator Model Data Sheets GENROU PSS®E Model Library 1.19 GENROU Round Rotor Generator Model (Quadratic Saturation) This model is located at system bus # IBUS, Machine identifier # ID, This model uses CONs starting with # and STATEs starting with The machine MVA is _ units = # K. Efd VT _ for each of MBASE. ZSORCE for this machine is on the above MBASE CONs J, Pm PMECH # EFD VOLT at Terminal Bus SPEED Speed ISORCE Source Current GENROU ETERM ANGLE _+j Value Description J T´do (>0) (sec) J+1 T´do (>0) (sec) J+2 T´qo (>0) (sec) J+3 Tqo (>0) (sec) J+4 H, Inertia Terminal Voltage Angle J+5 D, Speed damping J+6 Xd J+7 Xq J+8 X´d J+9 X´q J+10 Xd = Xq J+11 Xl J+12 S(1.0) J+13 S(1.2) Note: Xd, Xq, X´d, X´q, Xd, Xq, Xl, H, and D are in pu, machine MVA base. Xq must be equal to Xd. All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 1-44 PSS®E 33.5 PSS®E Model Library Generator Model Data Sheets GENROU STATEs # Description K E´q K+1 E´d K+2 kd K+3 kq K+4 speed (pu) K+5 Angle (radians) IBUS, ’GENROU’, ID, CON(J) to CON(J+13) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 1-45 PSS®E 33.5 PSS®E Model Library Generator Model Data Sheets GENSAL 1.21 GENSAL Salient Pole Generator Model (Quadratic Saturation on d-Axis) This model is located at system bus # IBUS, Machine identifier # ID, This model uses CONs starting with # and STATEs starting with # The machine MVA is MBASE. J, Pm PMECH EFD Efd VT K. _ for each of units = VOLT at SPEED Speed ISORCE Source Current GENSAL ETERM Terminal Bus ANGLE ZSORCE for this machine is on the above MBASE. CONs _+j # Value Terminal Voltage Angle Description J T´do (>0) (sec) J+1 Tdo (>0) (sec) J+2 Tqo (>0) (sec) J+3 H, Inertia J+4 D, Speed damping J+5 Xd J+6 Xq J+7 X´d J+8 Xd = Xq J+9 Xl J+10 S(1.0) J+11 S(1.2) Note: Xd, Xq, X´d, Xd, Xq, Xl, H, and D are in pu, machine MVA base. Xq must be equal to Xd. STATEs # Description K E´q K+1 kd K+2 q K+3 speed (pu) K+4 Angle (radians) IBUS, ’GENSAL’, ID, CON(J) to CON(J+11) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 1-47 EXCITER MODELS B) Exciter Data (IEEET1):S.No Parameter Description 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Symbol as per PSSE Voltage transducer time constant (s) AVR steady state gain (pu) AVR equivalent time constant (s) Max. AVR output (pu) Min. AVR output (pu) Exciter feedback time constant (pu) Exciter time constant (s) Stabilizer feedback gain (pu) Stabilizer feedback time constant (s) Switch Exciter saturation point 1 (pu) Exciter saturation factor at point 1 Exciter saturation point 2 (pu) Exciter saturation factor at point 2 PSS®E 33.5 PSS®E Model Library TR (sec) KA TA (sec) VRMAX or zero VRMIN KE or zero TE (>0)(sec) KF TF(>0)(sec) Switch=0 E1 SE(E1) E2 SE(E2) Excitation System Model Data Sheets CELIN 6.5 CELIN ELIN Excitation System This model is at system bus # _ IBUS, Machine identifier # _ ID, This model uses CONs starting with # _ J, and STATEs starting with # _ K, and VARs starting with # _ L. CONs # Value Description J TR1 J+1 TR2 J+2 TR3 J+3 J+4 J+5 TE2 J+6 Nominal full load EFD in IEEE pu1 J+7 KE2 J+8 TR4 J+9 T1 J+10 T2 J+11 T3 J+12 T4 J+13 T5 J+14 T6 J+15 K12 J+16 K2 J+17 p_PSS J+18 a_PSS J+19 Psslim J+20 K1 J+21 KIEC J+22 KD1 J+23 TB1 (>0) J+24 T11 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-13 PSS®E 33.5 Excitation System Model Data Sheets CELIN CONs # PSS®E Model Library Value Description J+25 LIMMAX_PID1 J+2 LIMMIN_PID1 J+27 K21 J+28 Spare J+29 Up+ J+30 Up- J+31 K3 J+32 T13 J+33 K4 J+34 T14 J+35 KETB J+3 TE J+37 Xp J+38 Ief max12 J+39 Ief max23 J+40 Ief min J+41 E1 J+42 SE(E1) J+43 E2 J+44 SE(E2) 1 Should be adjusted to the specific machine. 2 Corresponds to the ceiling of 1.6 pu. 3 This limit is actually disabled. STATEs K # Description Sensed Vt K+1 Uw K+2 Ub K+3 Efd K+4 Sensed lef K+5 PSS_first lag K+ PSS_second lag K+7 PSS_first washout K+8 PSS_second washout K+9 PSS_third washout All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-14 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets CELIN STATEs # Description K+10 PSS_third lag K+11 PID1_rate-lag K+12 PID1_integrator K+13 Spare K+14 PID3_integrator K+15 PID4_integrator K+1 Converter_lag VARs L L+1 # Description IEF, pu IEF_REF, pu IBUS, ’CELIN’, ID, CON(J) to CON(J+44) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-15 PSS®E 33.5 Excitation System Model Data Sheets CELIN PSS®E Model Library 0 p_PSS 2 F(s) = a_PSS[B(s)(1 - p_PSS) + V(s)(1 - |p_PSS - 1|)] 2 p_PSS 4 F(s) = a_PSS[B(s)(3 - p_PSS) + V(s)(1 - |p_PSS - 3|)] All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-16 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets CELIN EXCITER FIELD CURRENT REGULATOR THYRISTOR CONVERTER Vt Up+ 1ef min ref Up+ + 1efref + 1ef ' – 1 Vr KK 21 2 + KETB + 1 + sTE – Up- XP Vt Up– 1ef max 1 ref Vef XP Ief EXCITER FIELD CURRENT MINIMUM LIMITER +3.56KIEC 1 sT13 0 + 1e f min + + K3 +3.56KIEC 1ef ' – BRUSHLESS EXCITATION 1ef min ref 0 + EXCITER FIELD CURRENT MAXIMUM LIMITER – +0 1 sTE2 Efd 1 sT14 Ief –3.56KIEC 1ef max 1 + + + K4 1ef ' – SE + KE2 +0 1e f max 1 ref –3.56K IEC Ief 1 1 + sTR4 DT02_004 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-17 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets ESDC1A 6.16 ESDC1A IEEE Type DC1A Excitation System This model is located at system bus #_ IBUS, ECOMP Machine identifier #_ ID, This model uses CONs starting with #_ J, VOTHSG and STATEs starting with #_ K, VUEL and VAR #_ L. VOEL CONs # Value ESDC1A EFD Description TR (sec) J J+1 KA J+2 TA (sec) J+3 TB (sec) J+4 TC (sec) J+5 VRMAX or zero J+6 VRMIN J+7 KE or zero J+8 TE (>0) (sec) J+9 KF J+10 TF1 (>0) (sec) J+11 0.0 Switch J+12 E1 J+13 SE(E1) J+14 E2 J+15 SE(E2) STATEs K # Description Sensed VT K+1 Lead lag K+2 Regulator output, VR K+3 Exciter output, EFD K+4 Rate feedback integrator All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-39 PSS®E 33.5 Excitation System Model Data Sheets ESDC1A VAR PSS®E Model Library # Description L KE IBUS, ’ESDC1A’, ID, CON(J) to CON(J+15) VS EC (pu) + 1 – 1 + sTR VC + – VUEL 1 + sTC 1 + sTB HV Gate VREF / VRMAX KA 1 + sTA VRMIN + VR EFD – VFE 0 VF 1 sTE + KE + VX = EFD SE (EFD) VS = VOTHSG + VOEL sKF 1 + sTF1 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-40 PSS®E 33.5 Excitation System Model Data Sheets EXAC1A PSS®E Model Library 6.25 EXAC1A IEEE Modified Type AC1 Excitation System This model is located at system bus Machine identifier # # This model uses CONs starting with and STATEs starting with # # IBUS, ECOMP _ ID, XADIFD _ J, VOTHSG _ K. VUEL _ EXAC1A EFD VOEL CONs # Value Description J TR (sec) J+1 TB (sec) J+2 TC (sec) J+3 KA J+4 TA (sec) J+5 VRMAX J+6 VRMIN J+7 TE > 0 (sec) J+8 KF J+9 TF > 0 (sec) J+10 KC J+11 KD J+12 KE J+13 E1 J+14 SE(E1) J+15 E2 J+16 SE(E2) All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-60 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets EXAC1A STATEs # Description K Sensed ET K+1 Lead lag K+2 Regulator output K+3 VE K+4 Feedback output IBUS, ’EXAC1A’, ID, CON(J) to CON(J+16) VREF VS 1 – 1 + sTR VC VRMAX + + EC (pu) / + KA + 1 + sTA VR 1 + sTC 1 + sTB – VE 1 sTE – VRMIN EFD FEX 0 FEX = f(IN) VFE VF IN + sKF KCIFD IN = V E 1 + sTF + IN KE + SE If IN 0. F If IN 0.433 F If 0.433 < I < 0.75 N F If IN 0.75 F If IN > 1 F EX EX EX KD IFD = 1 = 1 – 0.577 I N = 0.75 – I 2 FEX = 1.7321 – I N EX EX = 0 VS = VOTHSG + VUEL + VOEL All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-61 PSS®E 33.5 Excitation System Model Data Sheets IEEET1 PSS®E Model Library 6.39 IEEET1 IEEE Type 1 Excitation System This model is located at system bus #_ IBUS, Machine identifier #_ ID, This model uses CONs starting with #_ J, VOTHSG and STATEs starting with #_ K, VUEL and VAR #_ L. VOEL CONs # ECOMP Value J IEEET1 EFD Description TR (sec) J+1 KA J+2 TA (sec) J+3 VRMAX or zero J+4 VRMIN J+5 KE or zero J+6 TE (>0) (sec) J+7 KF J+8 TF (>0) (sec) J+9 0 Switch J+10 E1 J+11 SE(E1) J+12 E2 J+13 SE(E2) STATEs # Description Sensed VT K K+1 Regulator output, VR K+2 Exciter output, EFD K+3 Rate feedback integrator VAR L # Description KE IBUS, ’IEEET1’, ID, CON(J) to CON(J+13) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-88 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets IEEET1 VE = SE × EFD VE + VREF 1 1 + sTR – + + VS KE VRMAX + EC (pu) + – KA 1 + sTA VR + 1 sTE EFD (pu) – VRMIN sKF 1 + sTF VS = VOTHSG + VUEL + VOEL Note: SE is the saturation function. All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-89 PSS®E 33.5 Excitation System Model Data Sheets IEEET2 PSS®E Model Library 6.40 IEEET2 IEEE Type 2 Excitation System This model is located at system bus #_ IBUS, Machine identifier #_ ID, This model uses CONs starting with #_ J, VOTHSG and STATEs starting with #_ K, VUEL and VAR #_ L. VOEL CONs # ECOMP Value J IEEET2 EFD Description TR (sec) J+1 KA J+2 TA (sec) J+3 VRMAX or zero J+4 VRMIN J+5 KE J+6 TE (>0) (sec) J+7 KF J+8 TF1 (>0) (sec) J+9 TF2 (>0) (sec) J+10 E1 J+11 SE(E1) J+12 E2 J+13 SE(E2) STATEs # Description Sensed VT K K+1 Regulator output, VR K+2 Exciter output, EFD K+3 First feedback integrator K+4 Second feedback integrator VAR L # Description KE All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-90 PSS®E 33.5 PSS®E Model Library Excitation System Model Data Sheets IEEET2 IBUS, ’IEEET2’, ID, CON(J) to CON(J+13) / VE = SE × EFD + VREF 1 – 1 + sTR + + KE VRMAX – + EC (pu) VE + KA 1 + sTA – VR + 1 sTE EFD (pu) VRMIN VS 1 1 + sTF2 sKF (1 + sTF1) VS = VOTHSG + VUEL + VOEL Note: SE is the saturation function. All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-91 PSS®E 33.5 Excitation System Model Data Sheets SCRX PSS®E Model Library 6.57 SCRX Bus Fed or Solid Fed Static Exciter This model is located at system bus # ECOMP IBUS, _ Machine identifier # _ ID, This model uses CONs starting with # _ J, and STATEs starting with # VOTHSG VUEL K. _ SCRX VOEL EFD XADIFD ETERM CONs # Value Description TA/TB J J+1 TB (>0) (sec) J+2 K J+3 TE (sec) J+4 EMIN (pu on EFD base) J+5 EMAX (pu on EFD base) J+6 CSWITCH1 J+7 rc / rfd2 1 Set C SWITCH = 0 for bus fed. Set CSWITCH = 1 for solid fed. 2 Set CON(J+7) = 0 for exciter with negative field current capability. Set CON(J+7) > 0 for exciter without negative field current capability. (Typical CON(J+7) = 10) STATEs K # Description First integrator K+1 Second integrator IBUS, ’SCRX’, ID, CON(J) to CON(J+7) VREF / E CSWITCH = 0 MAX CSWITCH = 1 1.0 Et + EC (pu) – 1 + TAs K 1 + T Bs 1 + TEs + Ebridge X LadIfd Negative Current Logic EFD EMIN VS VS = VOTHSG + VUEL + VOEL All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 6-130 GOVERNOR MODELS C) Governor Data (TGOV1):S.No Parameter Description 1 2 3 4 5 6 7 Symbol as per PSSE Permanent Droop Governor time constant Maximum valve position limit Minimum valve position limit time constant Reheater time constant Turbine Damping PSS®E 33.5 PSS®E Model Library R T1 (>0)(sec) V MAX V MIN T2 (sec) T3 (>0)(sec) Dt Turbine-Governor Model Data Sheets HYGOV 7.9 HYGOV Hydro Turbine-Governor This model is located at system bus IBUS, #_ Machine identifier #_ ID, This model uses CONs starting with #_ J, and STATEs starting with #_ K, and VARs starting with #_ L. CONs # SPEED Speed Value J HYGOV Description R, permanent droop J+1 r, temporary droop J+2 Tr (>0) governor time constant J+3 Tf (>0) filter time constant J+4 Tg (>0) servo time constant J+5 + VELM, gate velocity limit J+6 GMAX, maximum gate limit J+7 GMIN, minimum gate limit J+8 TW (>0) water time constant J+9 At, turbine gain J+10 Dturb, turbine damping J+11 qNL, no power flow STATEs # Description K e, filter output K+1 c, desired gate K+2 g, gate opening K+3 q, turbine flow PMECH VARs L L+1 # Description Speed reference h, turbine head R, r, and Dturb are in pu on generator MVA base. IBUS, ’HYGOV’, ID, CON(J) to CON(J+11) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-25 PSS®E 33.5 Turbine-Governor Model Data Sheets HYGOV VAR(L) + nref 1 1 + Tfs e – Speed + SPEED PSS®E Model Library 1 + Trs rTrs c 1 g 1 + T gs Velocity and Position Limits SPEED + Dturb R X – g – X q h 1 Tws q + At + PMECH – + 1 X qNL All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-26 PSS®E 33.5 PSS®E Model Library Turbine-Governor Model Data Sheets GGOV1 7.8 GGOV1 GE General Governor/Turbine Model This model is located at system bus # _ IBUS, Machine identifier # _ ID, This model uses CONs starting with # _ J, and STATEs starting with # _ K, and VARs starting with # _ L, and ICONs starting with # _ M. CONs J # Value SPEED GGOV1 PMECH PELEC Description R, Permanent droop, pu J+1 Tpelec, Electrical power transducer time constant, sec J+2 maxerr, Maximum value for speed error signal J+3 minerr, Minimum value for speed error signal J+4 Kpgov, Governor proportional gain J+5 Kigov, Governor integral gain J+6 Kdgov, Governor derivative gain J+7 Tdgov, Governor derivative controller time constant, sec J+8 vmax, Maximum valve position limit J+9 vmin, Minimum valve position limit J+10 Tact, Actuator time constant, sec J+11 Kturb, Turbine gain J+12 W fnl, No load fuel flow, pu J+13 Tb, Turbine lag time constant, sec J+14 Tc, Turbine lead time constant, sec J+15 Teng, Transport lag time constant for diesel engine, sec J+16 Tfload, Load Limiter time constant, sec J+17 Kpload, Load limiter proportional gain for PI controller J+18 Kiload, Load limiter integral gain for PI controller J+19 Ldref, Load limiter reference value pu J+20 Dm, Mechanical damping coefficient, pu J+21 Ropen, Maximum valve opening rate, pu/sec J+22 Rclose, Maximum valve closing rate, pu/sec J+23 Kimw, Power controller (reset) gain J+24 Aset, Acceleration limiter setpoint, pu/sec J+25 Ka, Acceleration limiter gain All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-19 PSS®E 33.5 Turbine-Governor Model Data Sheets GGOV1 CONs # PSS®E Model Library Value Description J+26 Ta, Acceleration limiter time constant, sec ( > 0) J+27 Trate, Turbine rating (MW)1 J+28 db, Speed governor deadband J+29 Tsa, Temperature detection lead time constant, sec J+30 Tsb, Temperature detection lag time constant, sec J+31 Rup, Maximum rate of load limit increase J+32 Rdown, Maximum rate of load limit decrease 1 If the turbine rating [CON(J+27)] is greater than zero, the input PELEC is converted in the model to per unit on turbine rating base, else PELEC is converted to per unit on machine base. STATEs # K Description Machine Electrical Power Measurement K+1 Governor Differential Control K+2 Governor Integral Control K+3 Turbine Actuator K+4 Turbine Lead-Lag K+5 Turbine load limiter measurement K+6 Turbine Load Limiter Integral Control K+7 Supervisory Load Control K+8 Acceleration Control K+9 Temperature Detection Lead-Lag VARs L # Description Load Reference L+1 Output of Load Limiter PI Control L+2 Output of Governor PID Control L+3 Low Value Select Output L+4 Output of Turbine Actuator L+5 Output of Turbine Lead-Lag L+6 Supervisory Load Controller Setpoint, Pmwset L+7 . . . L+19 Delay Table L+20 Dead Band All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-20 PSS®E 33.5 PSS®E Model Library ICONs Turbine-Governor Model Data Sheets GGOV1 # Value Description Rselect, Feedback signal for governor droop: 1 electrical power M 1 0 none (isochronous governor) -1 fuel valve stroke (true stroke) -2 governor output (requested stroke) Flag Switch for fuel source characteristic: M+1 0 0 fuel flow independent of speed 1 fuel flow proportional to speed R and DM in pu on Turbine MW base when Trate is specified and in pu on generator MVA base when Trate is not entered. IBUS, ’GGOV1’, ID, ICON(M) and ICON(M+1), CON(J) to CON(J+32) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-21 PSS®E 33.5 Turbine-Governor Model Data Sheets GGOV1 governor output PSS®E Model Library All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies 7-22 International. PSS®E 33.5 PSS®E Model Library Turbine-Governor Model Data Sheets GGOV1 Notes: a. This model can be used to represent a variety of prime movers controlled by PID governors. It is suitable, for example, for representation of: • gas turbine and single shaft combined cycle turbines • diesel engines with modern electronic or digital governors • steam turbines where steam is supplied from a large boiler drum or a large header whose pressure is substantially constant over the period under study • simple hydro turbines in dam configurations where the water column length is short and water inertia effects are minimal b. Per unit parameters are on base of the turbine MW base (Trate). If no value is entered for Trate, parameters are specified on generator MVA base. c. The range of fuel valve travel and of fuel flow is unity. Thus the largest possible value of Vmax is 1.0 and the smallest possible value of Vmin is zero. Vmax may, however, be reduced below unity to represent a loading limit that may be imposed by the operator or a supervisory control system. For gas turbines Vmin should normally be greater than zero and less than wfnl to represent a minimum firing limit. The value of fuel flow at maximum output must be less than, or equal to unity, depending on the value of kturb. d. The parameter Teng is provided for use in representing diesel engines where there is a small but measurable transport delay between a change in fuel flow setting and the development of torque. In the majority of cases Teng should be zero. e. The parameter Flag is provided to recognize that fuel flow, for a given fuel valve stroke, can be proportional to engine speed. This is the case for GE gas turbines and for diesel engines with positive displacement fuel injectors. Flag should be set to unity for all GE gas turbines and most diesel engines. Flag should be set to zero where it is known that the fuel control system keeps fuel flow independent of engine speed. f. The load limiter module may be used to impose a maximum output limit such as an exhaust temperature limit. To do this the time constant Tfload should be set to represent the time constant in the measurement of temperature (or other signal), and the gains of the limiter, Kpload, Kiload, should be set to give prompt stable control when on limit. The load limit can be deactivated by setting the parameter Ldref to a high value. g. The parameter Dm can represent either the variation of engine power with shaft speed or the variation of maximum power capability with shaft speed. If Dm is positive it describes the falling slope of the engine speed versus power characteristic as speed increases. A slightly falling characteristic is typical for reciprocating engines and some aeroderivative turbines. If Dm is negative the engine power is assumed to be unaffected by shaft speed, but the maximum permissible fuel flow is taken to fall with falling shaft speed. This is characteristic of single shaft industrial gas turbines. h. This model includes a simple representation of a supervisory load controller. This controller is active if the parameter Kimw is non-zero. The load controller is a slow acting reset loop that adjusts the speed/load reference of the turbine governor to hold the electrical power output of the unit at its initial condition value Pmwset. All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-23 PSS®E 33.5 Turbine-Governor Model Data Sheets GGOV1 PSS®E Model Library Pmwset is given a value automatically when the model is initialized and stored in VAR(L+6), and can be changed thereafter. The load controller must be adjusted to respond gently relative to the speed governor. A typical value for K imw is 0.01, corresponding to a reset time of 100 seconds. Setting K imw to 0.001 corresponds to a relatively slow acting load controller. i. The parameters Aset, Ka, and Ta describe an acceleration limiter. These parameters may be set to zero if the limiter is not active. j. The parameter db is the speed governor dead band. This parameter is in terms of per unit speed. k. Tsa and Tsb are provided to augment the exhaust gas temperature measurement subsystem in gas turbines. l. Rup and Rdown specify the maximum rate of increase and decrease of the output of the load limit controller (Kpload/Kiload). All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-24 PSS®E 33.5 PSS®E Model Library Turbine-Governor Model Data Sheets TGOV1 7.21 TGOV1 Steam Turbine-Governor This model is located at system bus #_ IBUS, Machine identifier #_ ID, This model uses CONs starting with #_ J, and STATEs starting with #_ K, and VAR #_ L. CONs # SPEED Value J TGOV1 PMECH Description R J+1 T1 (>0) (sec) J+2 VMAX1 J+3 VMIN1 J+4 T2 (sec)2 J+5 T3 (>0) (sec)3 J+6 D t1 1 V MAX, VMIN, Dt and R are in per unit on generator MVA base. 2 T /T = high-pressure fraction. 2 3 3 T = reheater time constant. 3 STATEs # Description K Valve opening K+1 Turbine power VARs L # Description Reference IBUS, ’TGOV1’, ID, CON(J) to CON(J+6) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-61 PSS®E 33.5 Turbine-Governor Model Data Sheets TGOV1 PSS®E Model Library VMAX Reference VAR(L) + 1 1 1 + T 2s R 1 + T 1s 1 + T 3s – + PMECH – VMIN SPEED Dt All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 7-62 STABILIZER MODELS D) PSS Data (PSS2A):S.No Parameter Description Symbol as per PSSE 1 Washout Time constant - Signal 1 TW1 (>0) 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Washout Time Constant - Signal 1 Lag Time Constant - Signal 1 Washout Time Constant - Signal 2 Washout Time Constant - Signal 2 Lag Time Constant - Signal 2 Gain - Signal 2 Gain - Signal 2 Ramp Tracking Filter Lead Time Constant Ramp Tracking Filter Lag Time Constant Lead Time Constant - Phase Comp. Block 1 Stabilizer Gain Lag Time Constant - Phase Comp. Block 1 Lead Time Constant - Phase Comp. Block 2 Lag Time Constant - Phase Comp. Block 2 Stabilizer Output Maximum Stabilizer Output Minimum TW2 T6 TW3 (>0) TW4 T7 KS2 KS3 T8 T9 (>0) KS1 T1 T2 T3 T4 VSTMAX VSTMIN PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets IEE2ST 3.2 IEE2ST IEEE Stabilizing Model With Dual-Input Signals This model is located at system bus # Machine identifier IBUS, # ID, This model uses CONs starting with # J, Inputs Based on ICON(M) and ICON(M+2) Values and STATEs starting with # K, and VARs starting with # L, and ICONS starting with # M. CONs # Value Description J K1 J+1 K2 J+2 T1 (sec) J+3 T2 (sec) J+4 T3 (sec)1 J+5 T4 (>0) (sec) J+6 T5 (sec) J+7 T6 (sec) J+8 T7 (sec) J+9 T8 (sec) IEE2ST VOTHSG Auxiliary Signal J+10 T9 (sec) J+11 T10 (sec) J+12 LSMAX J+13 LSMIN J+14 VCU (pu) (if equal zero, ignored.) J+15 VCL (pu) (if equal zero, ignored.) 1 If T equals 0, sT will equal 1.0. 3 3 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-5 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets IEE2ST STATEs # Description K First signal transducer K+1 Second signal transducer K+2 Washout K+3 First lead-lag K+4 Second lead-lag K+5 Third lead-lag VARs # Description L Memory L+1 Derivative of pu bus voltage, first bus L+2 Memory L+3 Derivative of pu bus voltage, second bus ICONs # Value Description ICS1, first stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) 3 generator electrical power on MBASE base (pu) M 4 generator accelerating power (pu) 5 bus voltage (pu) 6 derivative of pu bus voltage M+1 IB1, first remote bus number M+2 ICS2, second stabilizer input code M+3 IB2, second remote bus number IBUS, ’IEE2ST’, ID, ICON(M) to ICON(M+3), CON(J) to CON(J+15) Input Signal #1 / K1 1 + sT1 + sT3 1 + sT4 1 + sT5 1 + sT6 1 + sT7 1 + sT8 + Input Signal #2 K2 1 + sT2 LSMAX 1 + sT9 1 + sT10 Output Limiter VS = VSS if (VCU > VCT > VCL) VSS LSMIN VS = 0 if (VCT < VCL) VOTHSG VS = 0 if (VCT > VCU) All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-6 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets IEEEST 3.3 IEEEST IEEE Stabilizing Model This model is located at system bus # Machine identifier IBUS, # ID, This model uses CONs starting with # J, and STATEs starting with # K, and VARs starting with # L, and ICONs starting with # M. CONs # Value Input Based on ICON(M) Value IEEEST VOTHSG Auxiliary Signal Description J A1 J+1 A2 J+2 A3 J+3 A4 J+4 A5 J+5 A6 J+6 T1 (sec) J+7 T2 (sec) J+8 T3 (sec) J+9 T4 (sec) J+10 T5 (sec)1 J+11 T6 (>0) (sec) J+12 KS J+13 LSMAX J+14 LSMIN J+15 VCU (pu) (if equal zero, ignored) J+16 VCL (pu) (if equal zero, ignored.) 1 If T equals 0, sT will equal 1.0. 5 5 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-7 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets IEEEST STATEs # Description K 1st filter integration K+1 2nd filter integration K+2 3rd filter integration K+3 4th filter integration K+4 T1/T2 lead-lag integrator K+5 T3/T4 lead-lag integrator K+6 Last integer VARs # L Memory L+1 ICONs Description Derivative of pu bus voltage # Value Description Stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) 3 generator electrical power on MBASE base (pu) M 4 generator accelerating power (pu) 5 bus voltage (pu) 6 derivative of pu bus voltage IB, remote bus number 2, 5, 6 1, 2 M+1 1 ICON(M+1) may be nonzero only when ICON(M) is 2, 5, or 6. 2 If ICON(M+1) is zero, the terminal quantity is used. IBUS, ’IEEEST’, ID, ICON(M) and ICON(M+1), CON(J) to CON(J+16) / Filter Input Signal 1 + A5s + A6s2 (1 + A1s + A2s2) (1 + A3s + A4s2) 1 + sT1 1 + sT2 1 + sT3 1 + sT4 Output Limiter LSMAX KS sT5 1 + sT6 VS = VSS, if (VCU > VCT > VCL) VSS LSMIN VS = 0, if (VCT < VCL) VOTHSG VS = 0, if (VCT > VCU) All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-8 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS1A 3.7 PSS1A IEEE Std. 421.5-2005 PSS1A Single-Input Stabilizer Model The PSS®E model IEEEST can be used to simulate the PSS1A model. The correspondence between the IEEEST model CONs and the PSS1A parameters (shown in the block) diagram are as given in the table below. CONs PSS1A parameter (as shown in the PSS1A block diagram) IEEEST CON J A1 A1 J+1 A2 A2 J+2 A3 TR J+3 A4 0.0 J+4 A5 0.0 J+5 A6 0.0 J+6 T1 T1 J+7 T2 T2 J+8 T3 T3 J+9 T4 T4 J+10 T5 Tw J+11 T6 Tw J+12 KS KS J+13 LSMAX VSTMAX J+14 LSMIN VSTMIN J+15 VCU 0.0 J+16 VCL 0.0 IBUS, ’IEEEST’, ID, ICON(M), ICON(M+1), CON(J) to CON(J+16) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-15 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS2A 3.8 PSS2A IEEE Dual-Input Stabilizer Model This model is located at system bus # IBUS, Machine identifier ID, # This model uses CONs starting with # J, and STATEs starting with # K, and VARs starting with # L, and ICONs starting with # M. CONs J # Value Input Based on ICON(M) Input Based on ICON(M+2) PSS2A VOTHSG Auxiliary Signal Description Tw1 (>0) J+1 Tw2 J+2 T6 J+3 Tw3 (>0) J+4 Tw4 J+5 T7 J+6 KS2 J+7 KS3 J+8 T8 J+9 T9 (>0) J+10 KS1 J+11 T1 J+12 T2 J+13 T3 J+14 T4 J+15 VSTMAX J+16 VSTMIN All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-16 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS2A STATEs # Description K Washout, first signal K+1 Washout, first signal K+2 Transducer, first signal K+3 Washout, second signal K+4 Washout, second signal K+5 Transducer, second signal K+6 . . . K+13 Ramp Tracking Filter K+14 First lead-lag K+15 Second lead-lag VARs # L Description Memory L+1 Derivative of pu bus voltage, first bus L+2 Memory L+3 Derivative of pu bus voltage, second bus ICONs # Value Description ICS1, first stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) M 3 generator electrical power on MBASE base (pu) 4 generator accelerating power (pu) 5 bus voltage (pu) 6 derivative of pu bus voltage M+1 REMBUS1, first remote bus number ICS2, second stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) M+2 3 generator electrical power on MBASE base (pu) 4 generator accelerating power (pu) 5 bus voltage (pu) 6 derivative of pu bus voltage All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-17 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS2A ICONs # Value Description M+3 REMBUS2, second remote bus number M+4 M, ramp tracking filter M+5 N, ramp tracking filter Model Notes: Ramp Tracking Filter M0 N0 M N 8 If M = 0, then N is set equal to 0 To bypass: set M = N = 0 Washouts To bypass second washout, first signal: set Tw2 = 0 To bypass second washout, second signal: set Tw4 = 0 Transducers To bypass first signal transducer: set T6 = 0 To bypass second signal transducer: set T7 = 0 Lead-Lags To bypass first lead-lag: set T1 = T2 = 0 To bypass second lead-lag: set T3 = T4 = 0 IBUS, ’PSS2A’, ID, ICON(M) to ICON(M+5), CON(J) to CON(J+16) / VSTMAX Input Signal #1 sTw1 1 + sTw1 sTw2 1 + sTw2 + 1 1 + sT6 + N 1 + sT8 (1 + sT9)M + – KS1 1 + sT1 1 + sT3 1 + sT2 1 + sT4 VOTHSG VSTMIN KS3 Input Signal #2 sTw3 1 + sTw3 sTw4 1 + sTw4 KS2 1 + sT7 All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-18 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS2B 3.9 PSS2B IEEE 421.5 2005 PSS2B IEEE Dual-Input Stabilizer Model This model is located at system bus Machine identifier # # This model uses CONs starting with _ IBUS, ID. # _ J, and STATEs starting with # _ K, and VARs starting with # _ L, and ICONs starting with # _ M. CONs J # Value Description Tw1 (> 0) J+1 Tw2 J+2 T6 J+3 Tw3 J+4 Tw4 J+5 T7 J+6 KS2 J+7 KS3 J+8 T8 J+9 T9 (> 0) J+10 KS1 J+11 T1 J+12 T2 J+13 T3 J+14 T4 J+15 T10 J+16 T11 J+17 VS1MAX J+18 VS1MIN J+19 VS2MAX J+20 VS2MIN J+21 VSTMAX J+22 VSTMIN All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-19 PSS®E 33.5 PSS®E Model Library Stabilizer Model Data Sheets PSS2B STATEs # Description K Washout-first signal K+1 Washout-first signal K+2 Transducer-first signal K+3 Washout-second signal K+4 Washout-second signal K+5 Transducer-second signal K+6 . . . K+13 Ramp tracking filter K+14 First lead-lag K+15 Second lead-lag K+16 Third lead-lag VARs L # Description Memory L+1 Derivative of pu bus voltage-first bus L+2 Memory L+3 Derivative of pu bus voltage-second bus All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-20 PSS®E 33.5 PSS®E Model Library ICON # Stabilizer Model Data Sheets PSS2B Value Description ICS1, first stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) M 3 generator electrical power on MBASE base (pu) 4 generator accelerating power (pu) 5 bus voltage 6 derivative of pu bus voltage M+1 REMBUS1, first remote bus to be entered as 0 for input codes 1, 3, and 4. ICS2, second stabilizer input code: 1 rotor speed deviation (pu) 2 bus frequency deviation (pu) M+2 3 generator electrical power on MBASE base (pu) 4 generator accelerating power (pu) 5 bus voltage 6 derivative of pu bus voltage M+3 REMBUS2, second remote bus to be entered as 0 for input codes 1, 3, and 4. M+4 M, ramp tracking filter M+5 N, ramp tracking filter IBUS, ’PSS2B’, ID, ICON(M) to ICON(M+5), CON(J) to CON(J+22) / All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies International. 3-21 PSS®E 33.5 Stabilizer Model Data Sheets PSS2B PSS®E Model Library All material contained in this documentation is proprietary to Siemens Industry, Inc., Siemens Power Technologies 3-22 International.