Stephen Errey

advertisement

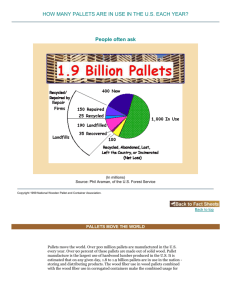

Stephen's Logistics Letter Tips, Advice And News To Improve Your Logistics UNITISATION - UGLY WORD, USEFUL CONCEPT Let me tell you, I wouldn't use a word like "unitisation" if there were any other. But unitisation is such a useful concept that I can't avoid it! And I'm sure you'll start using it too, once you learn how much time and money it can save you. So what's it all about? Well, let me take you back to the fundamentals of supply chain operations. If you're trying to improve your supply chain operations, you've got to look at activities which have the most effect. And that's got to include handling. Why is handling so crucial? Simply put, every time you handle something, you give yourself the opportunity to do something wrong, or to cause damage - and on top of that, you incur a cost. So, if you cut down the amount you handle your goods, then you're going to have happier customers (because not so much will go wrong) and a happier Finance Director (because you've cut your costs). This is where unitisation comes in. Obviously, you can't get rid of handling - after all, having a supply chain is all about moving things from one place to another. What we're talking about is making sure the way you handle your products suits what you have to do with them. And in particular, I'm thinking about the units of handling you choose. I guess the best way to explain to September 2013 you what I mean is to give you a few examples - good and bad. I'm sure you must have seen the way milk is stored in your local supermarket. A few years ago, it would always have been on a shelf in a chiller cabinet. Think about what that means - someone's spent time taking each carton off a pallet and putting it on the shelf. And while they're doing that, there's a chance they'll drop it, or put it in the wrong place, or make all sorts of other mistakes. These days, the chiller's designed to take a roll cage. So all the shelf stacker has to do is roll the cage into position - and the job's done. No wasted time, no damage, no mispicking. And you've probably seen the same kind of thing with other fast-moving products - drinks at Christmastime, for instance. On the other hand, it's not long ago I visited a warehouse where the pickers had to spend time - a lot of time - breaking the top layer of cases off their pallets and manually making up new pallets with the leftovers. All because their major customer wouldn't accept pallets of the size their production processes created. And I'm sure you can imagine the results of having to do that. Extra labour cost, of course - but also delayed shipments, poorly presented (and sometimes damaged) product. And occasionally mixed products on a pallet, if there had been a shift change in the middle of the repacking! So how can you make sure your unitisation suits your business? Well, first of all you've got to look at your whole supply chain. You can have a fantastically fast and efficient packaging line - but that doesn't help you, if two stages down your supply chain you've got to spend more time and money undoing everything it's done! Secondly, when you're doing this, it's really important to work back down the supply chain from your customers to production - and not the other way round. Find out what your customers want - and then design your units of handling back up from there. How many times have you found that your customers order in dozens, but everything's produced in tens - or the other way round! We all know that focussing on our customers is important - and here's a really good example of how you need that customer focus in all areas of your business. So, in a nutshell, what's the key message for you this month? Let's do something practical - have a look at how your orders are going out through your door, then have a look at how they're coming in. Now, how many times are you having to change their configuration on the way? If the answer's none, then that's great - and move on to something else! Otherwise, you've got something with great potential to go at!