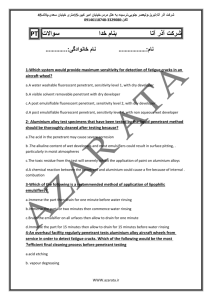

NDT100 - Penetrant Inspection

advertisement

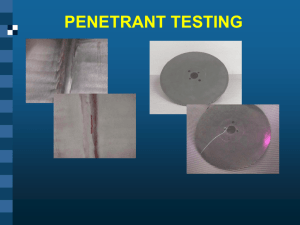

Course Standard XXX Liquid Penetrant Inspection Course Description In this course students will master the competencies associated with Liquid Penetrant testing at Level I and Level II. This course adheres to the standards developed by the American Society for Nondestructive Testing (ASNT) Laboratory work will parallel lecture materials from the classroom. Hours Credit 3 Prerequisite/Core requisite: Materials and Processes for NDT Inspection Course Guide Outcomes: The student will be apply all appropriate safety processes and procedures Competencies Identify safety processes associated with liquid penetrant testing Apply safety processes associated with liquid penetrant testing Outcomes: The student will be able to apply National Aerospace Standard (NAS410) to processes and procedures used in liquid penetrant testing Competencies Identify National Aerospace standard (NAS410) Identify the role of NAS410 in relation to aerospace industry and NDT Identify terminology associated with NAS410 Identify the NDT methods listed as common in NAS410 List the responsibilities identified by NAS 410 associated with various NDT certification levels List the qualifications identified by NAS 410 associated with various NDT certification levels Identify the training hours identified by NAS 410 associated with various NDT methods and certification levels Identify the experience hours identified by NAS 410 associated with various NDT methods and certification levels List the vision requirements identified by NAS 410 List the examination requirements identified by NAS 410 associated with various NDT certification levels Identify how NAS410 affects liquid penetrant method of NDT 10.17.08 Apply NAS410 standards to liquid penetrant NDT processes and procedures Outcomes: The student will be able to compare and contrast various types of liquid penetrant testing Competencies Introduction Discuss history of liquid penetrant inspection as an NDT method Discuss the purpose of liquid penetrant testing Identify the basic principles of liquid penetrant testing List the types of liquid penetrant testing Compare and contrast the types of liquid penetrant testing Identify the methods of personnel qualifications in relation to liquid penetrant testing Discuss unique aspects of applying liquid penetrant testing methods to the aviation industry Outcomes: The student will be able to demonstrate liquid penetrant processing techniques using aviation based projects and scenarios Processes Competencies Identify the process to prepare parts for liquid penetrant testing Identify lighting requirements for liquid penetrant testing Identify application process of penetrants to parts Identify removal process Identify the developer application and drying process Demonstrate effective procedures for application of liquid penetrant Identify process for inspection and evaluation of part subjected to liquid penetrant Demonstrate effective inspection and evaluation process using liquid penetrant Identify post cleaning processes Apply post cleaning processes Outcomes: The student will be able demonstrate various penetrant testing methods using aviation based projects and scenarios Methods Competencies Identify standards methods for penetrant testing including ASTM and ASME ( ASTME E 1208, 1209 and 210) Identify the characteristics for each standard Demonstrate each method Outcomes: The student will be able to utilize equipment and materials associated with liquid penetrant testing Equipment Competencies Identify equipment (testing units) associate with liquid penetrant Identify light required for testing equipment Identify light meters for testing equipment Identified materials utilized in liquid penetrant testing Utilize equipment and materials associated with liquid penetrant testing 10.17.08 Outcomes: The student will be able to select appropriate test for aviation based projects and scenarios Method selection Competencies Identify the limitations of each method Identify the advantages of each method Compare and contrast the various methods in order to select method appropriate for situation Outcomes: The student will be able to demonstrate the ability to perform liquid penetrant testing with multiple variables in aviation based scenario Impact of different factors Cracks Porosity Material forms Evaluation Indications Competencies Identify discontinuities inherent in various materials Identify the reasons for indications Identify the appearance of indications Identify amount of time the indications will take to appear Identify the persistence of the indications Identify the effects of temperature and lighting (white to UV) on the indications Identify the effects of metal smearing operations on the indications Demonstrate indications from time, persistence, temperature, lighting, metal smearing Identify the preferred sequence of penetrant inspection Indentify the methods for preparing parts for penetrant inspection Demonstrate methods for preparing parts for penetrant inspection Identify the factors which affect indications including type of penetrant used, prior processing and techniques used. Identify indications from cracks including those occurring during solidification, processing and service Demonstrate indications from cracks Identify indications resulting from porosity Demonstrate indications resulting from porosity Identify indications resulting from material forms including forgings, castings, plate, welds, extrusions Demonstrate indications resulting from various material forms Identify true indicators List false indicators List relevant indications List non relevant indications Identify methods for process control including controlling variables in the process and testing and maintenance of materials Suggested Resources List books, and other resources used here Nondestructive Testing Handbook 10.17.08 Air Force Technical Order 33B-1-1 Nondestructive Inspection Methods, Basic Theory 10.17.08