File - Quoc Tran`s E

advertisement

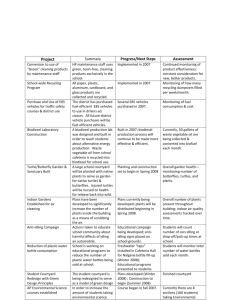

Tran 1 Quoc Tran Chemistry 213 Kristin Beiswenger April 21, 2015 Final Formal Report #2 Biodiesel from Coffee Grounds Biodiesel is growing to be a viable energy source as the conventional fossil fuels are being used rapidly. 1 Despite being less efficient than fossil fuel, biodiesel’s popularity as an alternative fuel comes from its biodegradable nature. From being used as an independent fuel source or mixing it with petroleum fossil fuels, biodiesel’s versatility has strong potential as sustainable source of energy. Today, biodiesel has been obtained through the conversion of natural biomass. One important use of natural product isolation aims to use bioconversion to recycling of wastes and to reduce landfills.2 It is typically synthesized through an transesterification process using waste vegetable oil, algal oil, or animal fat.3 Biodiesel’s resulting typical composition includes a range methyl and ethyl esters of fatty acids due to the transesterification’s fragmentations. In the base-catalyzed transesterification process involving coffee grounds, biodiesel was synthesized from triglycerides using methanol and potassium carbonate as shown in Scheme 1. 65°C, 45 min Scheme 1. Synthesis of Biodiesel through transesterification with base and alcohol Tran 2 The synthesis begins with the base catalyst deprotonating the hydrogen off the methanol group to form a nucleophilic methoxy group. The methoxy group then performs a backside attack on the carbonyl group of the triglycerides to form a tetrahedral intermediate. The electrons on negatively charged electrons shift back down to reform the double bond and break off a fatty acid methyl ester. Finally, the negatively charged oxygen on the initial triglyceride deprotonates methanol. The course of this nucleophilic attack, electron shift, bond fragmentation, and deprotonation repeats until glycerol, fatty acid methyl esters converted, and potassium carbonate is reformed. The course of this mechanism is demonstrated in Scheme 2.3 Tran 3 Scheme 2. Mechanism of Base Catalyzed Transesterification of Triglycerides and Fatty acid methyl esters. The purpose of this experiment is to synthesize biodiesel from spent coffee grounds using a basecatalyzed transesterification process. Since coffee grounds are used abundantly around the world, this experiment will test the efficiency in converting the natural waste to a possible green energy source. It will target high coffee waste generation sources such as Starbucks in hopes for possible commercial Tran 4 production of biodiesel.4 The first part of the experiment will isolate crude oil or triglycerides from the spent coffee grounds. Upon IR spectroscopy analysis of the triglycerides, the percent recovery of crude oil from the mass of coffee grounds will be calculated. The expected percent recovery of this oil based on the coffee grounds is about 15%.4 The isolation of the crude oil will be followed by the actual transesterification and purification of triglyceride oil to the biodiesel where there is an expected 100% yield The final product’s fatty acid methyl esters will be characterized with IR spectroscopy and GC/GC-MS data. The presence of the fatty acid methyl acids found in biodiesel will indicate the success of making biodiesel from spent coffee grounds. Experimental Triglycerides. Spent coffee grounds (50 g) were added to hexanes (150 mL). The reaction mixture was stirred and refluxed at 65°C for 1.5 hours. After cooling to room temperature, vacuum filtration was performed to isolate the liquid from the solid coffee grounds. The liquid was evaporated to afford a brown-yellow and sticky liquid (2.2026 g, 4% IR (ATR) υmax (cm-1) 2921.4, 2853.0, 1742.3, 1459.0, 1372.6, 1159.0. Biodiesel. Triglycerides (2.2026 g, 7.342 mmol) and potassium carbonate (0.165 g) were dissolved in methanol (10 mL). The reaction mixture was mixed and refluxed at 60°C -65°C for 45 minutes. Upon cooling to room temperature, the pH level of mixture was monitored upon adding acetic acid to neutralize any potassium carbonate. The neutral reaction mixture was separated by adding hexanes (10 mL) and 90% methanol/water (10 mL) with a liquid/liquid extraction in a reaction tube. The hexane layer was dried over sodium sulfate and evaporated to afford a slimy green and brown liquid (2.25 g, 24%) IR (ATR) υmax (cm-1) 2921.4, 2853.0, 1741.9, 1458.0, 1371.2, 1161.0; GC (phenyl methylpolysiloxane, 125°C to 275°C at 10°C per min) RT 7.9 min, 8.3 min, 9.5 min, 9.6 min, 9.8 min, Tran 5 9.9 min, and 11.5 min; GC-MS (phenyl methylpolysiloxane, 125°C to 275°C at 10°C per minute) RT 14.74 min, m/z 326; RT 12.98, m/z 298; RT 12.71 min, m/z 294; RT 11.07 min, m/z 270. Results, Discussion, and Conclusion In this experiment, biodiesel was synthesized via a transesterification reaction with triglycerides in the coffee’s isolated crude oil. The target product of biodiesel was purified using liquid/liquid extraction and characterized by IR and GC/GC-MS. In converting the crude oil to biodiesel, potassium carbonate was chosen as the base catalyst in this transesterification reaction. Potassium carbonate’s very basic properties allow it to deprotonate the hydrogens off methanol to form a nucleophilic methoxy group. This deprotonation initiated of the overall reaction to fragment various fatty acid methyl esters. As consequence of potassium carbonate’s basic nature, acetic acid was needed to neutralize the overall reaction mixture before the work-up of the biodiesel. By adding this acid, the reaction was stopped as the potassium carbonate could not continue to deprotonate the methanol. Over the course of this experiment, reaction mixtures were stirred and refluxed with a flask and reflux condenser. Rather than using a heat source and open beaker, refluxing hexanes and methanol was chosen to heat the reaction mixture. Refluxing permitted the boiling of the reaction mixture for long periods of time without loss of volume of the solvents or damaging the crude oil or biodiesel. In isolating biodiesel away from glycerol in the liquid reaction mixture, the purification technique of liquid/liquid extraction used hexanes 90% methanol/water to create an organic layer with the biodiesel and an aqueous layer with glycerol. Based on the polarities fatty acid methyl esters and glycerol, 90% methanol/water was used because it was easily able separate glycerol due to its hydrogen bonding interactions. The nonpolar hexanes were able to then take the less polar biodiesel into the top Tran 6 organic layer. This liquid/liquid extraction was performed in a reaction tube rather than a separatory funnel because small amounts of biodiesel were expected to be formed. Biodiesel was formed as a sticky greenish-brown liquid in a 24% yield. Furthermore, the percent recovery of the crude oil from the 50 grams of coffee grounds gave a 4% recovery. The functional groups of the product were characterized by IR and the purity was analyzed using GC/GC-MS. When characterizing the product, the IR analysis (Figure 1 and Figure 2, Supplemental Information) reflects very similar spectra for both the starting material of triglycerides and product of biodiesel. Since glycerol was separated during the liquid/liquid extraction, the absence of the hydroxyl functional group in the biodiesel’s spectra (Figure 2) helped confirm the product had similar functional groups with triglycerides. For example, the carbon-hydrogen scissor bend at 1459 cm-1 and methyl umbrella bend at a 1342 cm-1 indicates the similar types of bonding on the long carbon chains on triglycerides and fatty acid methyl esters. Additional carbon-hydrogen stretches at 2921 cm-1 represents the alkene carbon-hydrogen bonding. .Both the starting material and biodiesel also contain the key ester carbonyl groups that are found at 1742 cm-1. The signals at about 1160 cm-1 is indicative of a carbonoxygen stretch in the ester structures. While the IR analysis for the starting material and product suggest similar functional groups between the structures, it does not help confirm that the two materials are different. To distinguish difference, GC/GC-MS identified the range of fatty acid methyl esters in the product. The GC was able to express the number of components in the overall composition of biodiesel, while the GC-MS helped deduce the actual components. Table 1 shows the possible number of components and Table 2 summarizes the types of fatty acid methyl esters found in the product below. The four components found in the biodiesel include methyl arachisate, stearic acid, linoleic acid, and palmitic acid. Tran 7 Retention Time % (min) Area Composition 7.953 55721 28.50 8.298 11824 6.05 9.524 75892 38.82 9.563 19066 9.75 9.758 12002 6.14 9.874 16046 8.21 11.455 4928 2.52 Table 1. GC Data Component Methyl Arachisate Stearic Acid Linoleic Acid Palmitic Acid Retention Time (min) Area 14.74 145777 12.98 470446 12.71 2189506 11.07 1969842 Table 2. GC-MS Data m/z 326 298 294 270 % Composition 3.1 9.9 45.8 41.2 In conclusion, the base-catalyzed transesterification of biodiesel was successfully with on overall yield of 24%. From characterizing the functional groups using the IR spectra to determining its purity using GC/GC-MS data, biodiesel’s composition was determined. Since the percent yield is based on the purification of crude oil, liquid/liquid extraction could have been improved on. To increase the percent yield, a number of factors including changing the solvent of hexanes to a slightly higher polarity could have helped force more biodiesel into the organic layer. Perhaps changing the ratio between the solvent used to make the organic layer vs. the solvent used to make the aqueous layer could have been even higher. . Additionally, making sure that all the biodiesel was transferred carefully from glassware could also impact the over percent yield as well. In performing a larger scale experiment in synthesizing a substantial amount of biodiesel, a separatory funnel should be used for accurate mixing and collections in the future. Tran 8 References (1) K. Ramachandran, T. Sunganya; N. Nagendra Ghandi, Renewable and Sustainable Energy Reviews. 2015, 22, 410-418. (2) L. Casas; Y. Hernández; C. Mantell; N. Casdelo; E. Martinez de la Ossa, Journal of Chemistry. 2015, 2015, 1-9. (3) U. Schucahardt; R. Sercheli; R. Matheus Vargas, Journal of the Brazilian Chemical Society. 1998, 9, 199-210. (4) E. Moreira Santos; A. Paula de Carvalho Teixeira; F. Gontija da Silva, Fuel. 2015, 150, 408-414. (5) N. Kondamudi; S. Mohaptra; M. Misra, Journal of Agriculutral and Food Chemistry. 2008, 56, 11757-11760. Tran 9 Supplemental Information (Note: The notebook pages with the handwritten procedure, data, observations, and calculations sections are to be attached at the end.) Figure 1. IR of Triglycerides Figure 2. IR of Biodiesel Figure 3. GC of Biodiesel Figure 4. GC-MS of Biodiesel