Why We Buy Biodiesel - Iowa Renewable Fuels Association

advertisement

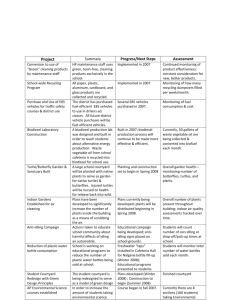

The Perils of Winter Biodiesel Blending Presentation to Iowa Renewable Fuels Association Michael Whitney Musket Corporation January 28, 2014 Topics • • • • • Why We Use Biodiesel Cold Weather and Quality Love’s/Musket Quality Protocols Labeling Transparency and D975 Incentives that Work Why We Buy Biodiesel 1. Biodiesel is Fuel • • • Quality Cost Ratability/scalability 2. RFS and State Incentives • • • Biodiesel is cheaper than diesel Drives competitiveness into our pricing Creates diversity of fuel supply We’re in the fuel business Cold Weather Challenges 1. Filter Plugging 1. 2. 3. 4. 5. Stranded truckers Driver downtime Missed loads – less biodiesel volume Higher maintenance costs Negative quality perceptions 2. Managing actual blend levels 1. ASTM D975 “up to 5%” 2. Calibrating blending systems 3. Handling preblends 3. Handling Issues 1. Insulated trailers 2. Hot load temps – temperature degradation 3. Additive Managing Cold Weather is an Industry Problem Improper Handling in Cold Weather Love’s Quality Program Quality Musket Spec ASTM D6751 < .4% < .8% < 200 seconds < 360 seconds Oxidation Stability > 6 Hours > 3 Hours Water < 300 ppm < 500ppm < .175% < .24% Monoglycerides Cold Soak Total Glycerine • • • Protect our brand on quality Protect our blending program Protect the industry A Quality Problem in Iowa is a Quality Problem Across the Country Love’s Quality Program • Every gallon of biodiesel comes from an approved plant that meets the Musket Spec • We visit and audit every plant for quality and compliance • We control blending accuracy and quality by taking supply directly to the stores where we blend it with diesel • We actively monitor the weather and proactively shut down blending • We look at not only where the truck fills up but where it could go • In Winter every diesel load that contains biodiesel must have cold weather additive “Up to 5%” - The ASTM D975 Dilemma • We don’t know how much we are getting • • • • We don’t know the quality of the biodiesel in the 5% • • Difficulty isolating potential biodiesel related quality issues Creates macro compliance issues on exports that damage RIN value • • • Makes it hard to be fully transparent to our customers State labeling and compliance issues Audit costs for FAME content testing of rack preblends Systematically weakens RIN value and blend margin Indirectly reduces producer margin Increases fuel cost to consumers • • • Forces us to reduce demand for biodiesel and fuel discount for blends above 5% Rack sellers price B5 at a clear ULSD value when there is not a clear ULSD option Degrades the value of product when shipping on a pipeline • Risk of blends above 20% invalidating engine warranties • New QAP rule Biodiesel Incentives that Work • Market oriented incentives that use achievable targets • RFS • Downstream tax incentives • IL, IA, TX • Mandates raises the cost of fuel and reduce supply availability • MN, OR, PA Policy makers are very focused on cost It is tricky to argue that something that is mandated must also be subsidized Questions?