Biodiesel from Coffee Grounds

advertisement

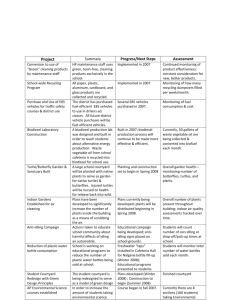

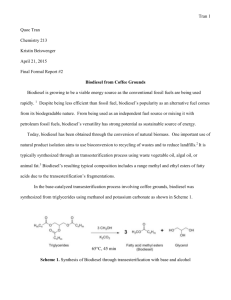

Ahmad Alhazeem Biodiesel from Coffee Grounds Introduction Natural products are products of natural origin including an entire organism that has not been processed, part of an organism, an extract of an organism or exudates and pure compounds isolated from plants, animals, or microorganisms1. There are a number of methods available for extraction and isolation of natural products from their various sources. In this experiment the natural product of biodiesel is isolated from coffee by a process that involves brewing the coffee, extracting the triglycerides and transesterification to yield the biodiesel. A lot of uses have been derived from natural products, especially plants, which mostly include in modern medicine and in the pharmaceutical industry1. The product of this experiment biodiesel, also known as fatty acid methyl esters, is obtained through transesterification of triglycerides with base and methanol. Biodiesel is the most widely accepted alternative fuel for diesel engines since it enhances biodegradability, reduces toxicity, improves lubricity and it is completely miscible with petroleum diesel2. There are many factors in which biodiesel can impact us where it can reduce trade deficit, create new jobs, contribute to reducing emissions to global warming, improve the quality of life by reducing the environmental and economic hazards, and help the farming community since the oil used to make biodiesel can be domestically grown3. 1 Ahmad Alhazeem The mechanism of the base catalyzed transesterification reaction of triglycerides to biodiesel is shown in Scheme 1. Methanol would first be deprotonated by the potassium carbonate base to form a methoxide ion, which is not shown in the mechanism. In the transesterification reaction, the carbonyl carbons of the triglycerides undergo a nucleophilic attack by the methoxide ions forming a tetrahedral intermediate. This intermediate would then proceed to form three equivalent molecules of biodiesel by rearrangement and another molecule that undergoes protonation to form glycerol. Scheme 1 2 Ahmad Alhazeem The purpose of this experiment is to isolate biodiesel from coffee by extracting the triglycerides first and then carrying out the synthesis of biodiesel through transesterification with base (potassium carbonate) and alcohol (methanol). Then characterize the content of the biodiesel obtained by IR, GC and GC-MS. Experimental Biodiesel. Coffee (75 g) was first brewed. The wet grounds were then spread onto some tinfoil and dried for 2 days in a 50 °C oven. After 2 days the dried coffee grounds (48 g), hexanes (150 mL) and a magnetic stir bar were placed in a 500 mL round bottom flask. The coffee/hexanes suspension was then refluxed with stirring at around 85 °C for 1.5 hours. After reflux the flask was first cooled to room temperature and the coffee grounds were separated from the hexanes using vacuum filtration where the liquid was kept. A stream of nitrogen was then used to isolate the pure/crude oil (2.855 g) which was later stored in a sealed container. Crude oil (2.855 g), methanol (0.623 g) and potassium carbonate (0.214 g) were placed in a round bottom flask and refluxed with stirring between 60-65 °C for 30 mins. When the reaction time ended, 1M acetic acid was slowly added until neutralization of the reaction mixture. Hexanes (10 mL) was later added to the flask and the solution was transferred to a large test tube. A solution of 90% methanol/water (5 mL) was then added where the layers were thoroughly mixed to allow them separate. A Pasteur pipette was used to extract the top hexanes layer where it was later dried over sodium sulfate. Evaporation of the hexanes from the solution eventually left with the final purified product of biodiesel (1.283 g, 44.9 %); IR (cm-1) 2922.5, 2853.0, 1741.6, 1459.8, 1436.0, 1169.3. GC (dichloromethane, 125 °C to 275 °C at 10 °C per min) RT (minutes) 13.67, 3 Ahmad Alhazeem 13.72, 15.34, 15.39, 15.61, 17.35; GC-MS (dichloromethane, 125 °C to 275 °C at 10 °C per min) RT 11.07 min, m/z 270; RT 12.72 min, m/z 294; RT 12.77 min, m/z 296; RT 12.98 min, m/z 298; RT 14.74 min, m/z 326. Results and Discussion The content of the biodiesel product obtained after the evaporation of hexanes was analyzed by IR, GC and GC-MS. The results of the IR analysis were compared with the expected values to verify the biodiesel product while the results of the GC and GC-MS analysis were used to calculate the composition of the biodiesel. The data was first analyzed using IR, which is shown in Figure 1. There are two peaks first seen at 2922.5 and 2853.0 cm-1which represent the alkane carbon-hydrogen bond expected at 2960-2850 cm-1. There is also two parts of the ester group that can be seen, which are the carbon-oxygen double bond expected at around 1735 cm-1 shown by a peak at 1741.6 cm-1 and the carbon-oxygen single bond expected at 1150-1060 cm-1 shown by a peak at 1169.3 cm-1. The last peaks that can be recognized are at 1459.8 and 1436.0 cm-1 that can either show the umbrella bend with an expected range of 1470-1430 cm-1 or the scissor bend with an expected range of 1490-1440 cm-1. The content of the biodiesel was also analyzed by GC followed by GC-MS. In the initial analysis of GC, the results shown in Figure 2 indicate that there are 6 components in biodiesel since there are 6 different peaks excluding the ones related to the solvent in the beginning. The 4 Ahmad Alhazeem peak at RT 15.34 min has the highest composition of 44.2% and the peak at RT 17.35 min has the lowest composition of 2.6%. Using the GC results, the data was further analyzed by GC-MS to identify the compounds of the different peaks using their mass spectrum where the results are shown in Figure 3. Unlike GC, there were 5 components that could be identified by GC-MS which were hexadecanoic acid, 9,12-Octadecanoic acid (Z,Z), 9-Octadecanoic acid (Z), Octadecanoic acid and Eicosanoic acid which are all methyl ester. The results show that 9,12Octadecanoic acid (Z,Z) has the highest composition of 40.4% and Eicosanoic acid has the lowest composition of 2.7%. Retention Time Area % Composition 13.67 6385 22.6% 13.72 3822 13.6% 15.34 12458 44.2% 15.39 2967 10.5% 15.61 1842 6.5% 17.35 726 2.6% Figure 2 5 Ahmad Alhazeem Component RT Area m/z % Composition Hexadecanoic 11.07 1969842 270 36.4% 12.72 2189506 294 40.4% 12.77 636143 296 11.8% 12.98 470446 298 8.7% 14.74 145777 326 2.7% acid 9, 12Octadecanoic acid (Z,Z) 9-Octadecanoic acid (Z) Octadecanoic acid Eicosanoic acid Figure 3 This isolation experiment has proved to be efficient in retaining the biodiesel from the crude oil through the transesterification reaction since it had a moderate yield of 44.9%. Some of the reasons that might not have made this yield higher are errors when calculating the amount of base and alcohol that need to be used, and when separating the layers of hexanes with glycerol where some of the hexanes layer was left behind. However the recovery of crude oil from the coffee grounds was low with 3.8% which was lower than usual since only 48g of coffee grounds was left after it was dried for a couple of days. This shows the extraction part of this experiment 6 Ahmad Alhazeem was not very efficient in obtaining the oil or that there isn’t much of triglycerides in the coffee grounds. Conclusion So in conclusion natural product isolation was used in this experiment to obtain the useful alternative fuel of biodiesel from coffee. The coffee grounds were first brewed and then left to dry for a couple of days. The dried coffee grounds were then used in extracting the triglycerides oil crude product. This crude oil was later used in carrying out the synthesis of biodiesel through transesterification with potassium carbonate and methanol where pure biodiesel was obtained as the final product. The content of the biodiesel was then analyzed by IR, GC and GC-MS to verify the identity of the biodiesel and determine its composition. The result of the IR analysis have shown that product is indeed biodiesel by having peaks matching with the expected values and the results of the GC with GC-MS analysis have shown that the biodiesel product has five different components that were identified. 7 Ahmad Alhazeem References: (1) Sarker, S., Latif, Z., Gray, A.; Natural Product Isolation, 2nd edition, Humana Press Inc., Totowa, NJ, 2006: pp 1-22. (2) Benjumea, P., Agudelo, J., Agudelo, A.; Basic Properties of Palm Oil Biodiesel-Diesel Blends, Fuel, Volume 87, Elsevier, Colombia, 2008: pp 2069-2075. (3) Ahmad, M., Khan, M., Zafar, M., Sultana, S.; Practical Handbook on Biodiesel Production and Properties, Taylor & Francis Group, FL, 2013: pp 1-8. 8