Experimental analysis of jute fiber and polyurethane composite

advertisement

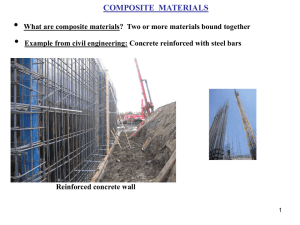

Experimental analysis of jute fiber and polyurethane composite Abstract— Natural fiber reinforced composites (NFRCs) are increasingly used in a variety of commercial applications, but there has been little theoretical, micromechanical modeling of structure/property relationships in these materials. Many of our modern technologies demand materials with unusual combination of properties such as high strength to weight ratio, high stiffness, high corrosion resistance, high fatigue strength, high dimensional stability etc. These can’t be met by conventional metal alloys. The scope of possible uses of natural fibers is enormous. Plenty of research work is done on natural fiber composites. But, woven jute fiber and bio based polyurethane resin matrix is not used for research studies. Literature review shows that composite made of combination of these constituents is not studied in order to know its properties. The present paper focus is on the experimental analysis and testing of untreated woven jute fiber and PUR composite. The tensile properties of natural fiber reinforced composites (NFRCs) are modeled using mathematical model. Mathematical model is used to investigate and predict the properties and fibre loads effect on mechanical properties. The combination of jute fibre with PU produced the material that is competitive to synthetic composites. Keywords— Jute Fiber, NFRC, PUR, Tensile strength I. INTRODUCTION Biocomposite is the composite having natural fiber and bio based resin matrix as its constituents. One of the limitations of biocomposites is the difficulty to predict the mechanical behavior due to the interface conditions between the natural fibers and the polymeric matrices. The elastic and tensile properties of NFRC can be experimentally determined or derived from a variety of mathematical models. In some cases, fiber aspect ratio, fiber volume fraction and fiber orientation are also included. In the present work, PU resin and woven jute fiber composite is subjected to experimental analysis. This paper outlines some of the recent reports published in literature on mechanical behavior of natural fiber based polymer composites with special emphasis on woven fiber reinforced polymer composites. The mechanical properties of a natural fiber-reinforced composite depend on many parameters, such as fiber strength, modulus, fiber content ,fiber length and orientation, in addition to the fiber-matrix interfacial bond strength. A strong fiber-matrix interface bond is critical for high mechanical properties of composites. A good interfacial bond is required for effective stress transfer from the matrix to the fiber whereby maximum utilization of the fiber strength in the composite is achieved. Modification to the fiber also improves resistance to moisture induced degradation of the interface and the composite properties. In addition, factors like processing conditions/techniques have significant influence on the mechanical properties of fiber reinforced composites. Mechanical properties of natural fibers, especially flax, hemp, jute and sisal, are very good and may compete with glass fiber in specific strength and modulus. A number of investigations have been conducted on several types of natural fibers such as kenaf, hemp, flax, bamboo, and jute to study the effect of these fibers on the mechanical properties of composite materials. Vasanta V Cholachagudda, Udayakumar P A, Ramalingaiah, presented ”Mechanical characterisation of Coir and rice husk reinforced Hybrid polymer composite’’[1]. They have chosen coir fiber as the major reinforcement and rice husk as an additional fiber to improve the mechanical property of polymer composite with vinyl ester as the base material prepared by hand layup process according to ASTM standards. Test specimens are prepared with different weight fractions of coir fiber at the optimization point of tensile test a small percentage of rice husks are added and tests were conducted and the improvement in mechanical properties Avtar Singh et al. [2]. Performed a Study of Mechanical Properties of Hybrid Natural Fiber Composite. Samples of several Jute-Bagasse-Epoxy & Jute-Lantana camara-Epoxy hybrids were manufactured using hand layup method were kept at 40%-60%. With increase of fiber loading capacity by 20%, the flexural strength value increases to 155.5MPa for Jute-bagasse and 310.9MPa for jute-lantana camara. The tensile strength of epoxy is 62-72 MPa wit 3-4 % elongation and with increase of fiber loading capacity by 20 % the tensile strength increases. Dixit S. and Verma P [3]. Studied The Effect of Hybridization on Mechanical Behavior of Coir/Sisal/Jute Fibers Reinforced Polyester Composite Material. Coir and jute reinforced polyester composite (CJRP), jute and sisal reinforced polyester composite (JSRP) were evaluated experimentally. The tensile and flexural properties of hybrid composites are markedly improved as compare to unhybrid composites. Water absorption behavior indicated that hybrid composites offer better resistance to water absorption. M. Porfiri and N. Gupta, [4] presented a paper on effect of volume fraction and wall thickness on the elastic properties of hollow particle filled composites and developed a modeling scheme to estimate elastic constant. Fiber content is the chosen parameter which affects the tensile properties of composite. M. Mohamed, S. Anandan, Z. Huo, V. Birman, J. Volz, K. Chandrashekhara [5] evaluated stiffness load carrying capacity of composite with thermoset polyurethane resin system as a matrix. MATERIALS AND PROCESSING A. Materials The materials used in the present research work are tabulated in TABLE I with their properties. Materials Jute Fiber Polyurethane Resin (Urecast 70) Hardener PU Specifications Fiber density:1.46 g/cc Single fiber length:120-150 mm Tensile strength: 393-800 MPa Density: 1.300 0.500 g/cc Viscosity at 27oC : 5000 500 mPa.s Curing time for Optimum properties : 6 hrs at RT and post cure at 80-90 o C – 4 hrs or 4-5 days at RT Flexural strength: 360-370 kg/ cm2 E Modulus: 4500 N / mm2 Impact strength notched : 2.6-3.0 kg/ cm2 Deflection at Break: 4.0 Adhesive Strength: 155 kg /cm2 Density: 1.220 0.100 g/cc Viscosity: 300 100 mPa.s TABLE I Specifications of the Materials Used in the Research B. Processing of Woven jute/Polyurethane Composite. First make some sample preparation calculation before preparing the woven jute fiber and PUR composite. Firstly Mould releasing agent is applied on inner surface of both mould plates. A rectangular mould of size 600x150x3mm is used for manufacturing of composite laminate. The calculated amount of resin with thoroughly mixed promoters, accelerators and hardener (PU resin: PU Hardener, 100:25 % by weight) and after 5-10 minutes it is made ready for pouring into mould with fibers. Resin is applied by using brush on the lower plate of mould. Woven fiber layer is then kept over resin layer. As per thickness required, number of layers is evaluated and alternatively fiber layers and resin are arranged. At last upper mould plate is kept over lower one and pressure is applied by fixed using C-clamps and bolts. It is then heated in a furnace at 600 for an hour. The setup for 24 hours to complete cure the laminate and once the laminate is completely cured then it’s ready for machining according to ASTM standard for testing, repeat the procedure by adding 32, 44, 50, 55% wt of jute fiber to the resin. Fig. 1 Composite laminate prepared using Hand layup process C. Sample Preparation Composite laminate of 150 mm X 300 mm X 3 mm were fabricated according to ASTM standards for mechanical tests. 1) Density of PU (δ) = 1.35 g/cm3 2) Volume of the mold (V) = 600x150x3mm =270000 mm3 = 270 cm3 3) Mass of resin (m) =Volume of mould x Density of PUR = cm3 x g/cm3 = 364.5g ≈ 365g. Samples % wt of Jute A B C D E F G 0 30 42 48 51 53 54 % of PUR resin Matrix 100 70 58 42 49 47 46 Mass of jute fiber (g) Mass of PUR resin (g) Total Mass (g) 0 75 105 120 127.5 132.5 135 250 175 140 125 122.5 117.5 115 250 250 250 250 250 250 250 TABLE II Samples Preparation Calculation for Woven Jute/PUR Composite The above samples are tested for mechanical properties that are tensile strength and tensile modulus (Modulus of elasticity, Young’s Modulus) according ASTM standards. III. MECHANICAL CHARACTERISATION Composite materials were subjected to various mechanical tests to measure strength, elastic constants, and other material properties. The results of such tests were used for two primary purposes: 1) engineering design (for example, failure theories based on strength, or deflections based on elastic constants and component geometry) and 2) quality control either by the materials producer to verify the process or by the end user to confirm the material specifications. A Universal Testing Machine (UTM) is an instrument used for the measurement of loads and the associated test specimen deflections such as those encountered in tensile, compression or flexural modes. It is used to test the tensile properties of materials (constituent and composite). Load cells and extensometers measure the key parameters of force and deformation as the samples were tested. The Universal Testing Machine set up is shown in Fig.2 (a) 1) Ultimate tensile strength = Maximum load in N in MPa.…………………….…… (1) C/s area 2) Young’s modulus (E) = Stress in GPa……….……………………………..…….……… (2) Strain 3) Stress (σ) = Load (l ) in N/mm2… ………………………………………………… (3) Area(b d ) 4) Strain = change in length / Original length…………………………………………………(4) C/s area in mm2 P = maximum load in N, b = width of the specimen in mm, d = thickness of the specimen in mm B. Tensile Test Report TABLE IV Tensile Strength of Woven Jute / Polyurethane Composite Samples A B C D E F % wt of Jute fiber 30 42 48 51 53 54 TS in MPa 18.545 21.383 33.025 33.29 33.71 36.52 53.52 66.585 69.043 78.727 82.1 87.11 Avg TS in MPa 19.964 33.1575 35.115 60.0525 73.885 84.605 Fig.3 (a) Variation of UTS with jute fiber loading Fig.2 Universal Testing Machine. (a) Universal testing machine set up and loaded tensile test specimens. A. Ultimate Tensile Strength Ultimate tensile strength, often referred to tensile strength is the maximum stress that a material can withstand while being stretched or pulled before fracture. The tensile test for the specimens was conducted according to ASTM D 638-03. The specimens of size 200 mm x19 mm x 3mm were tested with a span length of 200 mm in tensile mode at a cross head speed of 10 mm / min. Instantaneous values for load, deflection, stress and strain were gathered and plotted using software. The specimen used for the tensile testing, UTM gripper and strain gauge extensometer is shown in Fig. 2(b) Strain Gauge Gripper Fig.2 (b)-Strain gauge mounted on specimen B. Tensile Test Report Fig.3.2-Single fiber test Sr. No Sample Tensile Strength Identification (MPa) 1 No.1 79.16 2 No.2 98.04 3 No.3 78.82 TABLE V Ultimate Tensile Strength Of Single Jute fiber CONCLUSION The conclusion of the study of woven jute fiber and PUR composite is that there is significant increase in the tensile strength of the composite. Tensile strength of the composite increases but there is a variation in rate of rise of tensile strength and modulus (in tension) with increase in fiber loading. 1. With the addition of woven jute the tensile strength increases from 19.964 MPa at 32% fiber loading and there is sudden rise at 44% jute fiber. Tensile strength for this fiber content is 33.157 MPa. 2. There is a gradual rise in tensile strength Up to 50% of fiber loading. 3. There is a sudden rise in tensile strength at 53%. After 53% (up to 56%) slope of curve seems to remain constant. 4. It is observed from the curve that from rate of change of tensile strength from 32% to 50% is is greater than that of from 53% to 56%. Theoretically (as per mathematical models) slope for tensile property vs. Vf plot remains constant. Conclusion From experimental test results1. From 30-40% of Vf slope is constant and curve is seemed to be linear. 2. Rate of increase of tensile strength is lesser from 30-40% than that of from 48-51% 3. From 51-54% tensile strength is showing rapid rate of rise in value. 4. Tensile modulus curve is having constant slope for initial modulus values (i.e.-from 30-42% Vf) evaluated experimentally. 5. From Vf-42-50% rate of change of modulus slightly decreases. 6. From 50-54% rate of change of tensile modulus increases ACKNOWLEDGMENT I am thankful to the Department of Mechanical Engineering staff and also Prof. A.V. Salve , VIIT institute of technology, Prof. Y.S. Munde , Cummins college of engineering and co-author Mr. Sagar Kulkarni for their support to carry out this research work. REFERENCES [1] M. Porfiri and N. Gupta, “Effect of Volume Fraction and Wall Thickness on the Elastic Properties of Hollow Particle Filled Composites,” Composites Part B: Engineering, Vol. 40, No. 2, 2009, pp. 166173. doi:10.1016/j.compositesb.2008.09.002 [2] K. Hbaieb, Q. Wang, Y. H. J. Chia and B. Cotterell, “Modeling Stiffness of Polymer/Clay Nanocomposites,”Po-lymer,Vol.48,No.3,2007,pp.901-909. doi:10.1016/j.polymer.2006.11.062 [3] Avtar Singh Saroya and Vishvendra Meena, “Study of Mechanical Properties of Hybrid Natural Fiber Composite”, National Institute of Technology, Rourkela. [4] ”Mechanical characterisation of Coir and rice husk reinforced Hybrid polymer composite’’ Vasanta V Cholachagudda 1, Udayakumar P A 2, Ramalingaiah 3 [5] Dixit S. and Verma P, “The Effect of Hybridization on Mechanical Behavior of Coir/Sisal/Jute Fibers Reinforced Polyester Composite Material”, Research Journal of Chemical Sciences, www.isca.in, ISSN 2231-606, Vol. 2(6), 91-93, June 2012. [6] Bledzki AK, Jaszkiewicz A, Scherzer D. Natural fibre and biocomposites for technical applications. Bioplast Mag 2008;3(02):12–5. [7] Bledzki AK, Mamun AA, Faruk O. Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composite. Express Polym Lett 2007; 1:755–62. [8] Mathew P, Oksman K, Sain M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose. J Appl Polym Sci 2005; 97(5):2014–25. [9] Shibata M, Ozawa K, Teramoto N, Yosomiya R, Takeishi H. Biocomposites made from short abaca fiber and biodegradable polyesters. Macromol Mater Eng 2003; 288(1):35 43. [10] Einsiedel R. Cordenka reinforced PLA – advanced bio-derived composite material. In: Proceedings of annual technical conference (ANTEC), Orlando, Florida, USA; 2010. [11] http://www.ctan.org/tex-archive/macros/latex/contrib/supported/IEEEtran