Job Posting

advertisement

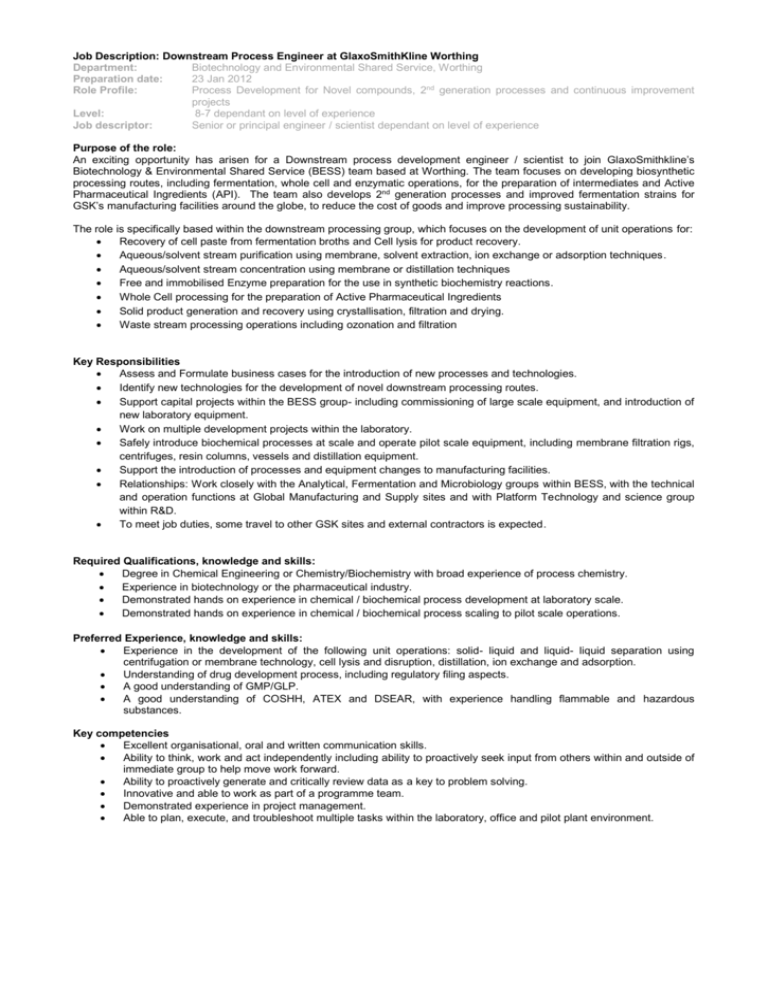

Job Description: Downstream Process Engineer at GlaxoSmithKline Worthing Department: Biotechnology and Environmental Shared Service, Worthing Preparation date: 23 Jan 2012 Role Profile: Process Development for Novel compounds, 2nd generation processes and continuous improvement projects Level: 8-7 dependant on level of experience Job descriptor: Senior or principal engineer / scientist dependant on level of experience Purpose of the role: An exciting opportunity has arisen for a Downstream process development engineer / scientist to join GlaxoSmithkline’s Biotechnology & Environmental Shared Service (BESS) team based at Worthing. The team focuses on developing biosynthetic processing routes, including fermentation, whole cell and enzymatic operations, for the preparation of intermediates and Active Pharmaceutical Ingredients (API). The team also develops 2nd generation processes and improved fermentation strains for GSK’s manufacturing facilities around the globe, to reduce the cost of goods and improve processing sustainability. The role is specifically based within the downstream processing group, which focuses on the development of unit operations for: Recovery of cell paste from fermentation broths and Cell lysis for product recovery. Aqueous/solvent stream purification using membrane, solvent extraction, ion exchange or adsorption techniques. Aqueous/solvent stream concentration using membrane or distillation techniques Free and immobilised Enzyme preparation for the use in synthetic biochemistry reactions. Whole Cell processing for the preparation of Active Pharmaceutical Ingredients Solid product generation and recovery using crystallisation, filtration and drying. Waste stream processing operations including ozonation and filtration Key Responsibilities Assess and Formulate business cases for the introduction of new processes and technologies. Identify new technologies for the development of novel downstream processing routes. Support capital projects within the BESS group- including commissioning of large scale equipment, and introduction of new laboratory equipment. Work on multiple development projects within the laboratory. Safely introduce biochemical processes at scale and operate pilot scale equipment, including membrane filtration rigs, centrifuges, resin columns, vessels and distillation equipment. Support the introduction of processes and equipment changes to manufacturing facilities. Relationships: Work closely with the Analytical, Fermentation and Microbiology groups within BESS, with the technical and operation functions at Global Manufacturing and Supply sites and with Platform Technology and science group within R&D. To meet job duties, some travel to other GSK sites and external contractors is expected. Required Qualifications, knowledge and skills: Degree in Chemical Engineering or Chemistry/Biochemistry with broad experience of process chemistry. Experience in biotechnology or the pharmaceutical industry. Demonstrated hands on experience in chemical / biochemical process development at laboratory scale. Demonstrated hands on experience in chemical / biochemical process scaling to pilot scale operations. Preferred Experience, knowledge and skills: Experience in the development of the following unit operations: solid- liquid and liquid- liquid separation using centrifugation or membrane technology, cell lysis and disruption, distillation, ion exchange and adsorption. Understanding of drug development process, including regulatory filing aspects. A good understanding of GMP/GLP. A good understanding of COSHH, ATEX and DSEAR, with experience handling flammable and hazardous substances. Key competencies Excellent organisational, oral and written communication skills. Ability to think, work and act independently including ability to proactively seek input from others within and outside of immediate group to help move work forward. Ability to proactively generate and critically review data as a key to problem solving. Innovative and able to work as part of a programme team. Demonstrated experience in project management. Able to plan, execute, and troubleshoot multiple tasks within the laboratory, office and pilot plant environment.